Preparation method of carboxylated cellulose nanofiber hydrogel

A carboxylated cellulose and nanofiber technology, applied in electrophoretic plating, coating, electrolytic coating, etc., can solve the problems of poor electrical conductivity, achieve high porosity and moisture content, simple and fast preparation process, and excellent reaction conditions mild effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] Step 1): prepare a carboxylated cellulose nanofiber suspension with a mass percentage concentration of 0.25%, for use;

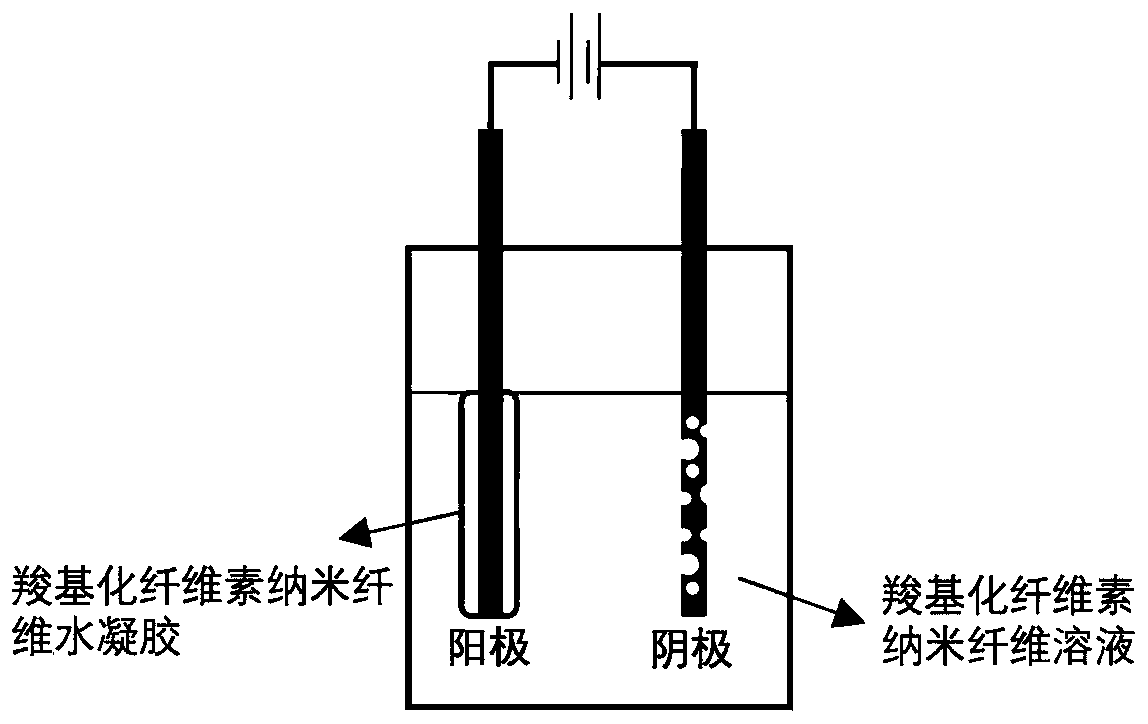

[0045] Step 2): prepare a stainless steel needle with a diameter of 1.5 mm as the anode material and a platinum wire with a diameter of 0.5 mm as the cathode material, which are used as the anode and cathode of electrophoretic deposition respectively;

[0046] Step 3): Immerse the anode material and the cathode metal material into the carboxylated cellulose nanofiber suspension, the insertion depth is 6mm, the spacing is 20mm, a constant current direct current is applied, the current value is 0.25mA, and the nanofiber is carried out. electrophoretic deposition, the deposition time is 120min;

[0047] Step 4): After the deposition, the carboxylated cellulose nanofiber hydrogel was obtained on the stainless steel needle anode.

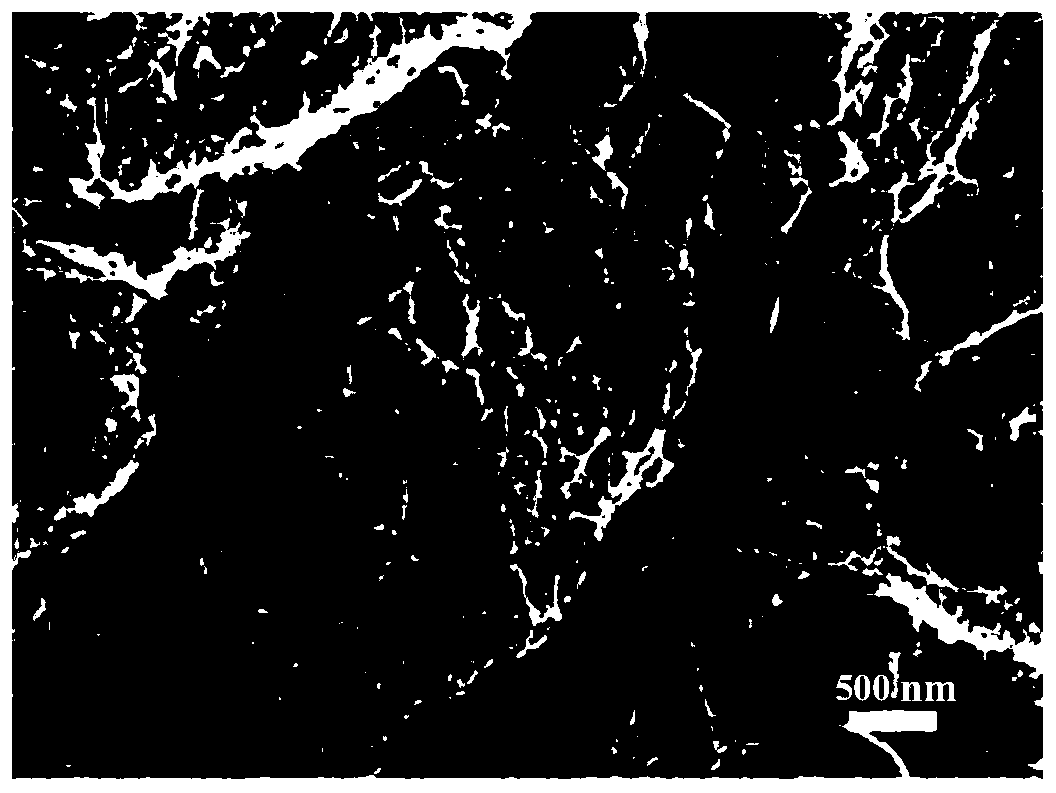

[0048] The carboxylated cellulose nanofibrous hydrogels obtained on the anode can reach a diameter of 1.2 cm (see Figure 2-...

Embodiment 2

[0050] Step 1): prepare a carboxylated cellulose nanofiber suspension with a mass percentage concentration of 0.25%, for use;

[0051] Step 2): prepare an iron wire with a diameter of 1.5 mm and a purity of 99.99% as the anode material and a platinum wire with a diameter of 0.5 mm as the cathode material, which are used as the anode and cathode for electrophoretic deposition, respectively;

[0052] Step 3): Immerse the anode material and the cathode metal material into the carboxylated cellulose nanofiber suspension, the insertion depth is 10mm, the spacing is 20mm, a constant current direct current is applied, the current value is 0.25mA, and the carboxylation is carried out. Electrophoretic deposition of cellulose nanofibers with a deposition time of 120 min;

[0053] Step 4): After the deposition, the carboxylated cellulose nanofiber hydrogel is obtained on the iron wire anode.

[0054] The carboxylated cellulose nanofiber hydrogel obtained on the anode is a carboxylated c...

Embodiment 3

[0056] Step 1): prepare a carboxylated cellulose nanofiber suspension with a mass percentage concentration of 0.1%, for later use;

[0057] Step 2): prepare a copper sheet with a size of 20mm×50mm×0.2mm and a purity of 99.99% as the anode material and a platinum sheet with a size of 15mm×20mm×0.1mm as the cathode material, respectively as the anode and cathode of electrophoretic deposition;

[0058] Step 3): Immerse the anode material and the cathode metal material into the carboxylated cellulose nanofiber suspension, the insertion depth is 15mm, the spacing is 15mm, a constant current direct current is applied, the current value is 1.0mA, and the carboxylation is carried out Electrophoretic deposition of cellulose nanofibers with a deposition time of 60 min;

[0059] Step 4): After the deposition, the carboxylated cellulose nanofiber hydrogel is obtained on the copper sheet anode.

[0060] The carboxylated cellulose nanofiber hydrogel obtained on the anode is a carboxylated ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com