Under-seed device for crystal growth

A technology of crystal growth and seed crystal, applied in the direction of crystal growth, single crystal growth, single crystal growth, etc., can solve the problem of easy falling off of the glue layer, and achieve the effect of simplifying the placement and fixing process of the seed crystal and reducing the heat loss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

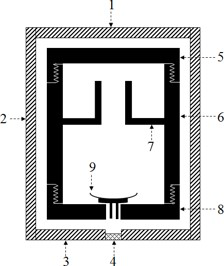

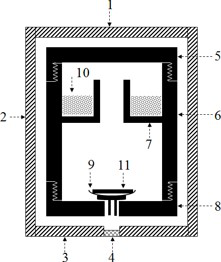

[0043] Embodiment 1: Growth of 3-inch high-purity SiC crystal

[0044] Unscrew the upper cover 5 and the lower bottom support 8 of the crucible structure, insert the wafer support frame 9 with a funnel-shaped structure with a platform inner diameter of 3 inches, put SiC powder 10 in the annular groove 7 on the inner wall of the crucible, and A seed crystal 11 with a diameter of 3 inches is put into the funnel-shaped wafer support frame 9, and the top cover 5 and the bottom bottom support 8 of the crucible structure are screwed on. The top cover 1 of the heat preservation structure, the middle cylinder 2 of the heat preservation structure, the bottom cover support 3 of the heat preservation structure, and the gasket 4 of the bottom of the heat preservation structure are tightly wrapped outside the crucible structure. The device of the present invention is placed in a closed chamber. Specifically, in the implementation process of silicon carbide crystal growth, usually under th...

Embodiment 2

[0046] Embodiment 2: Growth of 4-inch conductive silicon carbide crystal

[0047] Unscrew the upper cover 5 and the lower bottom support 8 of the crucible structure, insert the wafer support frame 9 with a funnel-shaped structure with a platform inner diameter of 4 inches, put silicon carbide powder 10 in the annular groove 7 on the inner wall of the crucible, Put the seed crystal 11 with a diameter of 4 inches on the funnel-shaped wafer support frame 9, and screw on the top cover 5 and the bottom bottom support 8 of the crucible structure. The top cover 1 of the heat preservation structure, the middle cylinder 2 of the heat preservation structure, the bottom cover support 3 of the heat preservation structure, and the gasket 4 of the bottom of the heat preservation structure are tightly wrapped outside the crucible structure. The device of the present invention is placed in a closed chamber. Specifically, during the implementation process of silicon carbide crystal growth, by...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com