Application of crystalline silicon micro-powder

A crystalline silicon and micropowder technology, which is applied in manufacturing tools, printed circuit manufacturing, grinding/polishing equipment, etc., can solve the problems of unstable large abrasive particles and high metal foreign matter content, and achieve low metal foreign matter content, low electrical conductivity, High whiteness effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] Example 1, the use of a crystalline silicon micropowder: the use is to use the crystalline silicon micropowder as an abrasive for roller brush grinding of printed circuit boards.

[0017] The mass percentage content of described crystalline silicon micropowder is: SiO 2 ≥99.0%, Al 2 o 3 2 o 3 ≤0.04%, CaO≤0.1%, MgO≤0.1%; water content≤0.1%; magnetic substance≤10.0ppm.

[0018] The particle size distribution of the crystalline silica powder is: D10=4.3±0.3 μm, D50=23.5±3.0 μm; D90=60.0±5.0 μm.

[0019] The whiteness of the crystalline silica powder is 50-95, the pH is 5.0-7.0, the specific gravity is 2.60, and the hardness is 6.5-7.0.

[0020] The electrical conductivity of the crystalline silica powder is 1-30µS / cm.

[0021] Prepared by conventional methods.

Embodiment 2

[0022] Example 2, the use of a crystalline silicon powder: the use is to use the crystalline silicon powder as an abrasive for roller brush grinding of printed circuit boards.

[0023] The mass percentage content of described crystalline silicon micropowder is: SiO 2 ≥99.0%, Al 2 o 3 2 o 3 ≤0.04%, CaO≤0.1%, MgO≤0.1%; water content≤0.1%; magnetic substance≤10.0ppm.

[0024] The particle size distribution of the crystalline silica powder is: D10=4.46 μm, D50=21.66 μm, D90=56.39 μm, D100=120.23 μm.

[0025] The whiteness of the crystalline silica powder is 50-95, the pH is 5.0-7.0, the specific gravity is 2.60, and the hardness is 6.5-7.0. The electrical conductivity of the crystalline silica powder is 1-30µS / cm.

Embodiment 3

[0026] Embodiment 3, using the crystalline silicon micropowder of the present invention and volcanic ash, corundum to make the comparative experiment of abrasive and its result:

[0027] 1. Chemical composition, see table 1 below:

[0028] Table I

[0029]

[0030] Crystalline silica powder metal oxide is much lower than volcanic ash.

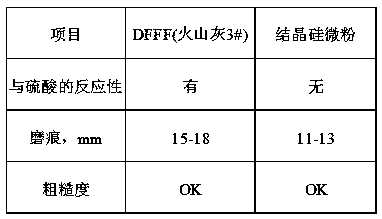

[0031] 2. Physical and chemical properties, see Table 2 below:

[0032] Table II

[0033]

[0034] Compared with volcanic ash, crystalline silica powder has slightly larger specific gravity, lower electrical conductivity and higher whiteness.

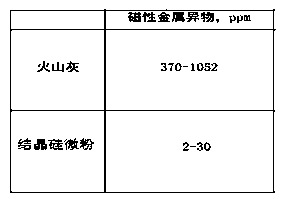

[0035] 3. Metal foreign matter, see Table 3 below:

[0036] Table three

[0037]

[0038] The magnetic metal foreign matter of crystalline silica powder is obviously less than that of volcanic ash.

[0039] 4. Particle size distribution, see Table 4:

[0040] Table four

[0041]

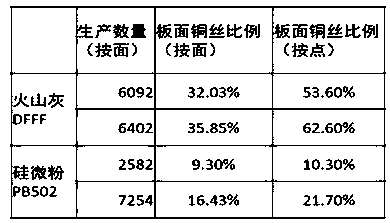

[0042] 5. Comparison of use effect - the proportion of copper wire on the board surface, see Table 5:

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

| Whiteness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com