Method for denitrifying flue gas by using rotary activated carbon denitrator

A denitrification device and activated carbon technology, applied in the field of flue gas denitrification, can solve the problems of not too high denitrification efficiency and poor adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

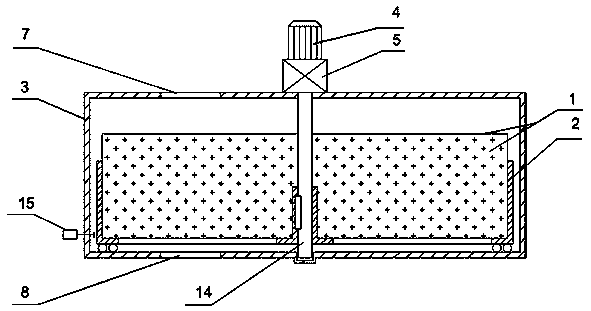

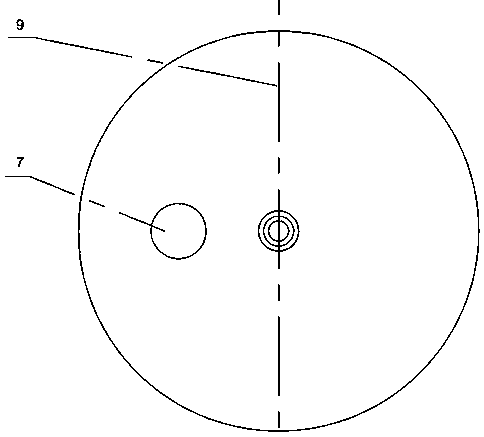

[0064] In conjunction with each accompanying drawing, the present invention is described in detail:

[0065] A steel pipe with a diameter of DN125 is used to quote the sintering flue gas from the sintering workshop of a steel factory. After measurement, the parameters of the initial flue gas are: flue gas temperature 135-137°C, flue gas velocity 3.6m / s, humidity 0.03%, NO content 178-193mg / m 3 , NO2 content 5-13mg / m 3 , the total content of nitrogen oxides is 191-212mg / m 3 , the oxygen content is 15.2%.

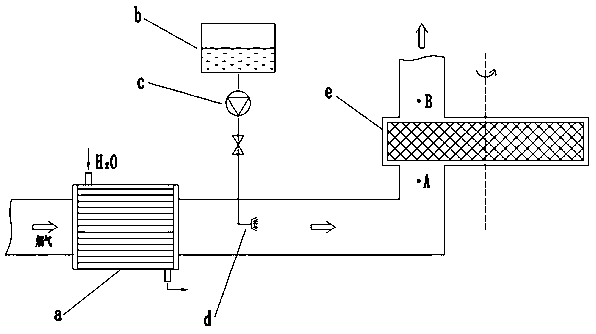

[0066] The flue gas first enters the shell-and-tube heat exchanger a, the heat exchange medium is cold water, the water goes through the shell side, and the flue gas goes through the tube side; after adjusting parameters such as water volume and water temperature, the temperature of the flue gas exiting the heat exchanger a is about 55°C; After the heat exchanger a, there is a sprayer d in the flue gas pipe, and the nozzle of the sprayer d atomizes the hydrogen peroxide, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com