Aluminum alloy engine cylinder block casting waste removal device and removal method

An engine block and casting waste technology, which is applied in the field of aluminum alloy engine block casting waste removal devices, can solve the problems of high equipment cost, many production line downtimes, and increased management items.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042]The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

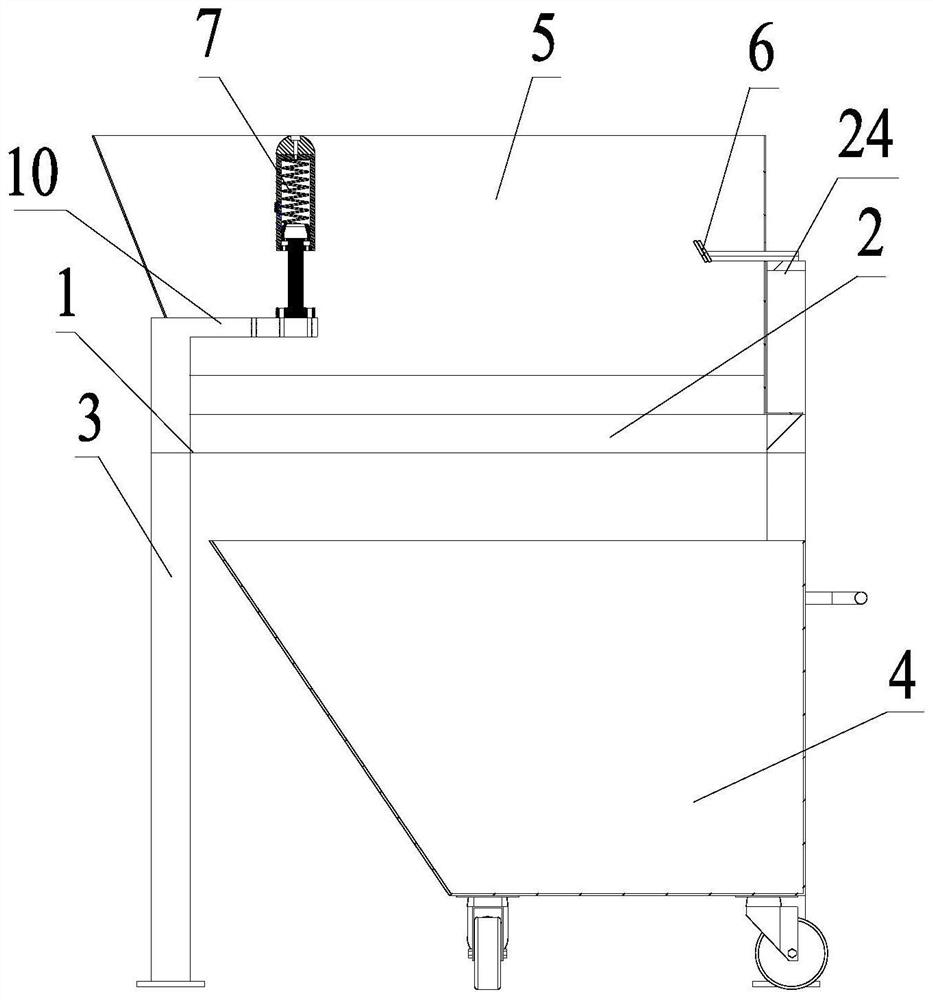

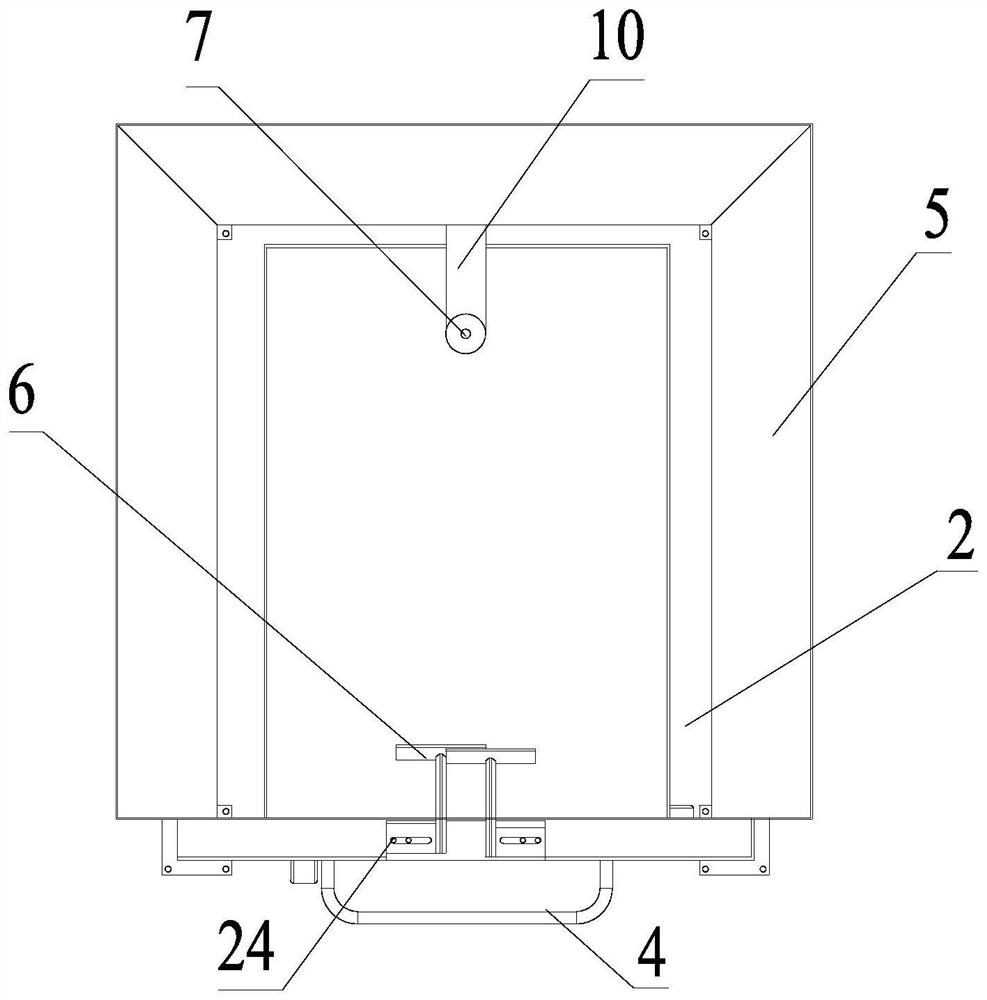

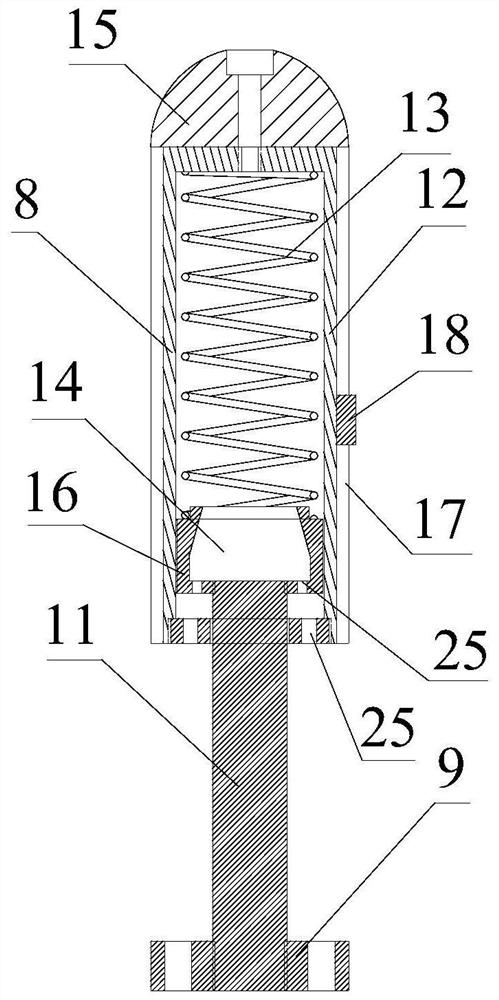

[0043] Such as figure 1 and figure 2 As shown, the aluminum alloy engine block casting waste removal device of the present invention includes a fuselage frame 1, and the fuselage frame 1 includes a horizontal quadrilateral fuselage frame 2 and four supporting feet 3 respectively located below the four corners of the fuselage frame 2 , the bottom of the fuselage frame 2 is provided with a movable waste collection vehicle 4, the top of the fuselage frame 2 is provided with a conical hopper 5, the outlet at the bottom of the hopper 5 matches the fuselage frame 2, and the fuselage frame 2 is provided with a slag The package impact plate 6 and the material handle impact pile 7, the slag package impact plate 6 and the material handle impact pile 7 are located in the hopper 5 and respectively located at both ends of the hopper 5, and the sl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com