Water-soluble chitosan derivative and preparation method thereof

A technology of water-soluble chitosan and chitosan derivatives, which is applied in the field of water-soluble chitosan derivatives and its preparation, can solve the problems of chitosan being insoluble in water, etc., and achieve the effect of expanding the application field

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

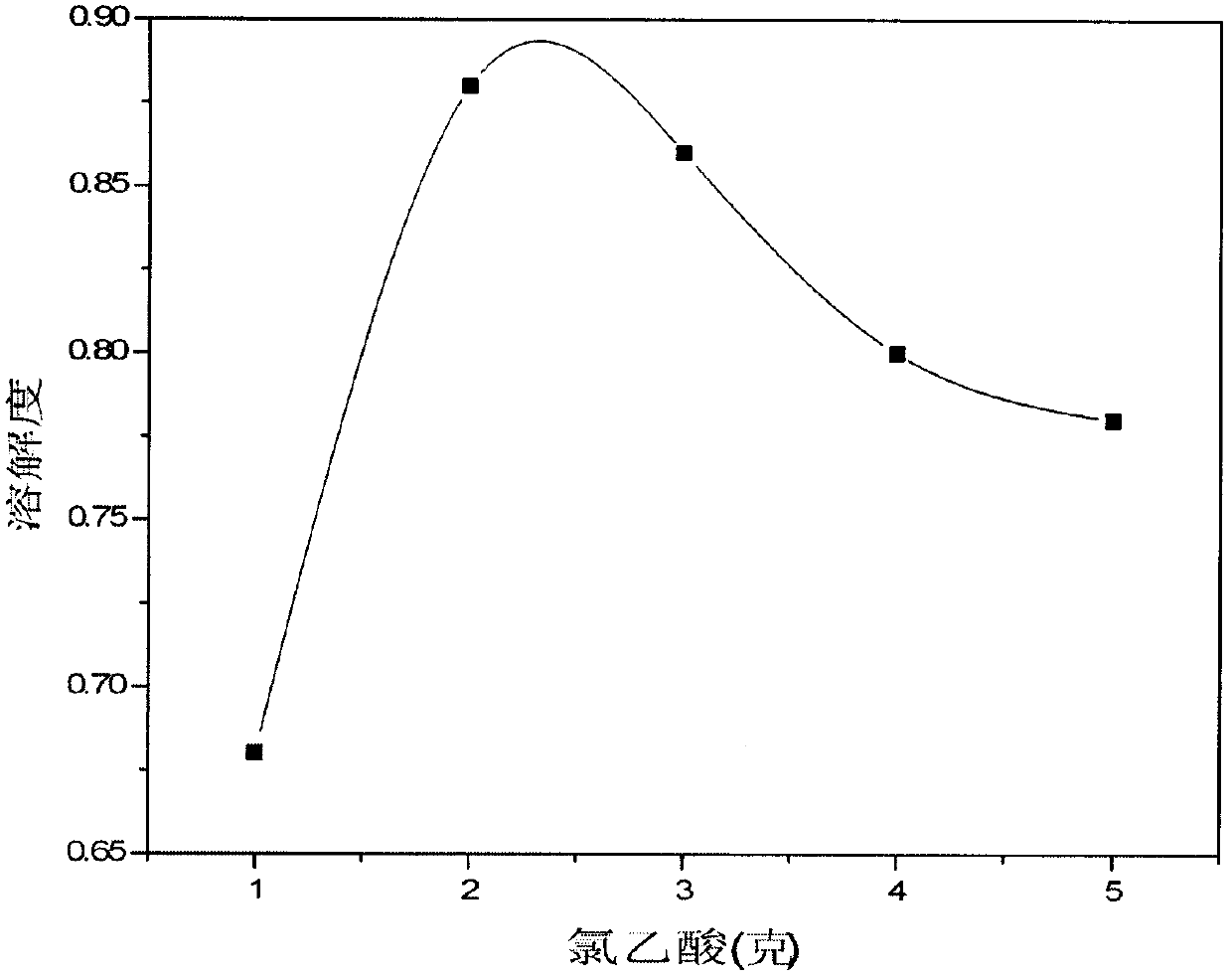

[0013] Weigh 5 parts of chitosan, each 1 gram, and disperse them in 5 three-necked bottles each containing 10 milliliters of isopropanol, place on a magnetic stirrer and stir and swell at room temperature for 30 minutes, then add dimethylformamide 5 milliliters, then add 25 milliliters of 40% NaOH solution, after stirring at room temperature for 3 hours, weigh chloroacetic acid respectively, make chitosan and chloroacetic acid mass ratio be 1: 1, 1: 2, 1: 3, 1: 4. 1:5, respectively added to the above reaction solution, and then transferred to a water bath at 60°C to reflux at a constant temperature for 8 hours, then poured into a beaker and cooled. Take a small amount of solution to see if it can be completely dissolved, if not, continue the reaction until it is completely dissolved. After the reaction is complete, add glacial acetic acid to the solution to adjust the pH value to 7.0, wash with absolute ethanol and acetone solution three times, filter with suction, stir and di...

example 2

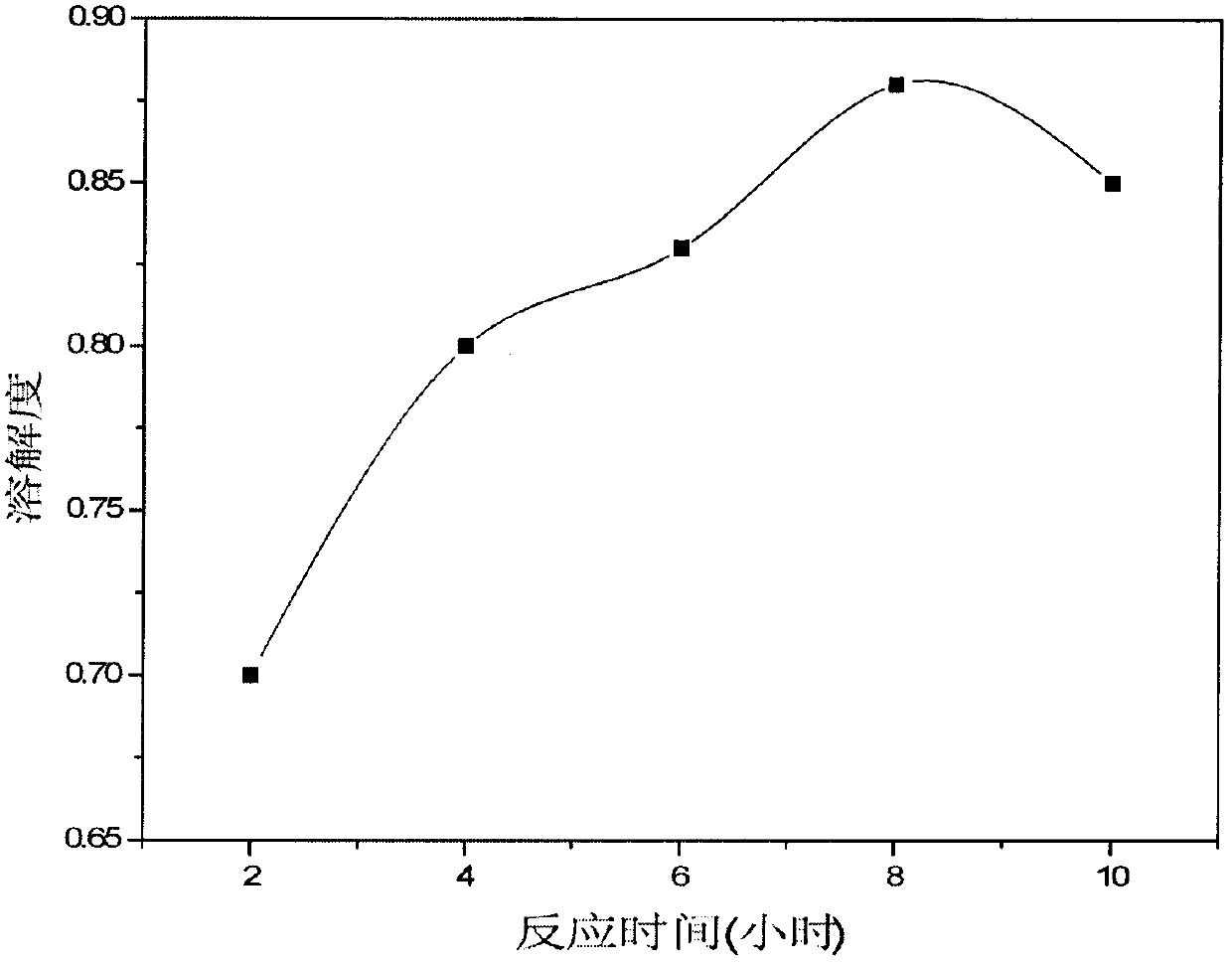

[0015] Weigh 5 parts of chitosan, each 1 gram, and disperse them in 5 three-necked bottles each containing 10 milliliters of isopropanol, place them on a magnetic stirrer and stir and swell at room temperature for 30 minutes, then add dimethyl formaldehyde Add 5 ml of amide, then add 25 ml of 40% NaOH solution, stir at room temperature for 2 hours, weigh chitosan and chloroacetic acid in a mass ratio of 1:2, add to the reaction solution, and then transfer to a water bath at 60°C After reflux at constant temperature for 2 hours, 4 hours, 6 hours, 8 hours, and 10 hours, pour it into a beaker and cool it down. Take a small amount of solution to see if it can be completely dissolved, if not, let it continue to react until it is completely dissolved. After the reaction is complete, add glacial acetic acid to the solution to adjust the pH value to 7.0, wash with absolute ethanol and acetone solution three times, filter with suction, stir and dissolve the obtained powder with deioniz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com