High-performance colorless transparent polyimide film and preparation method thereof

A transparent polyimide and polyimide resin technology, which is applied in the field of polymer materials, can solve the problems of reduced film comprehensive performance, excessive amino groups, polyamic acid resin adhesive, etc., and achieve heat resistance and dimensional stability Enhanced performance, excellent solvent resistance, and good mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] A kind of preparation method of high-performance colorless transparent polyimide film of the present invention, comprises the following steps:

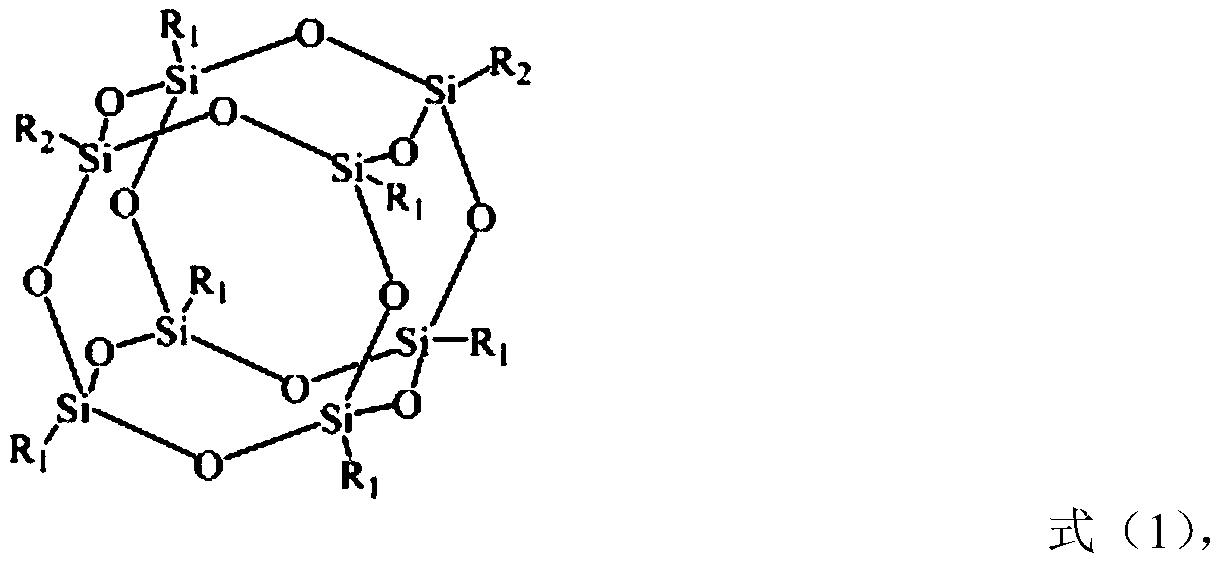

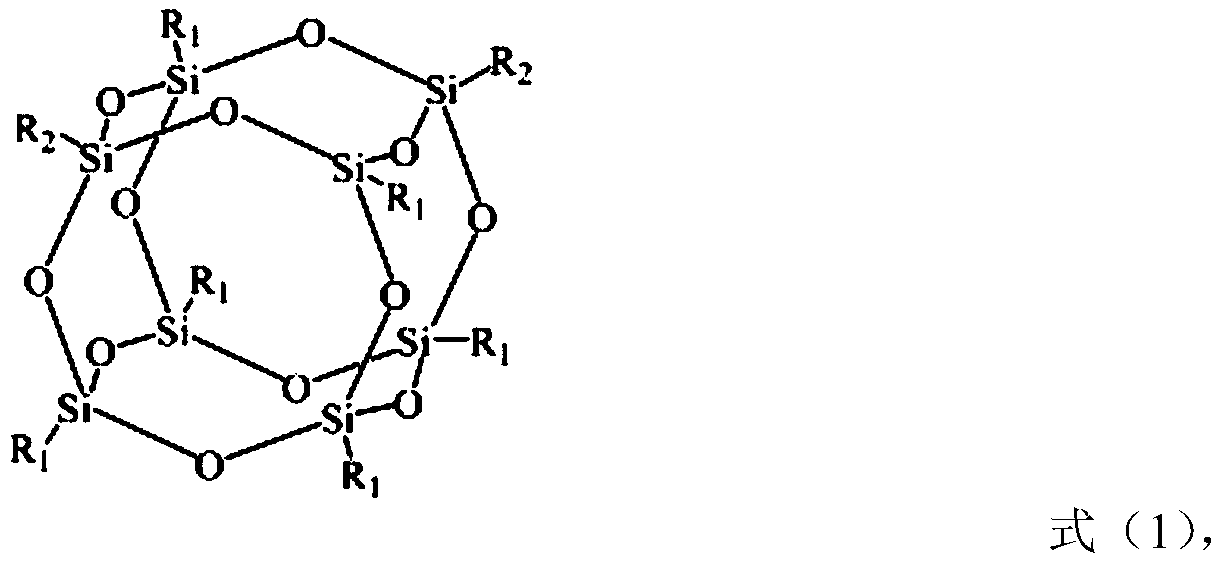

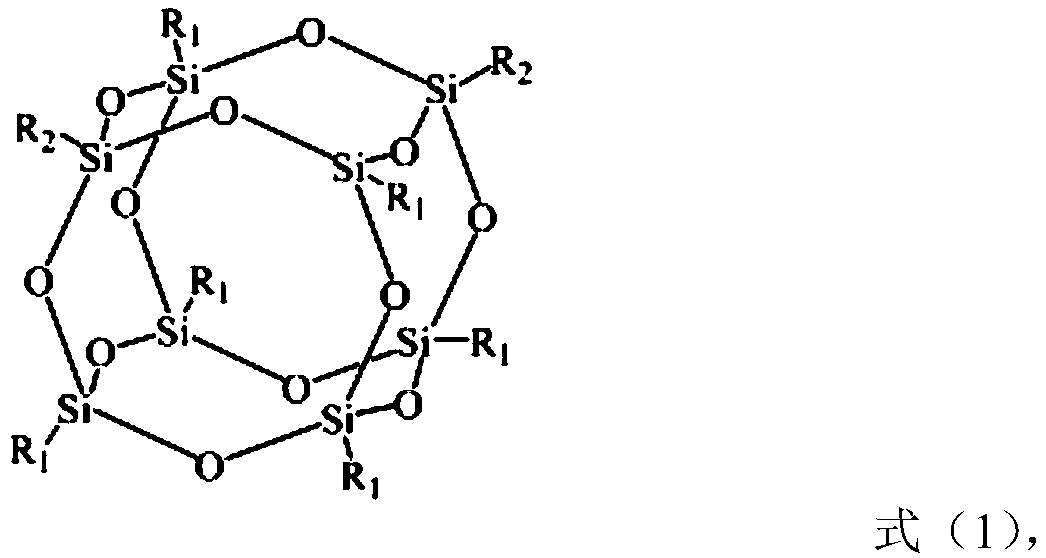

[0040] (1) Dissolve 15.504g (0.136mol) 1,4-cyclohexanediamine (CHDA) in 392g m-cresol at room temperature and under the protection of nitrogen, mechanically stir until completely dissolved and then add 63.78g (0.06mol) ) contains diamine with POSS structure, stir mechanically until it is completely dissolved, then add 26.8944g (0.12mol) 1,2,4,5-cyclohexane tetra-acid dianhydride (HPMDA) and 23.5376g (0.08mol) 4,4' -Biphenyltetracarboxylic dianhydride (4,4'-BPDA), heat up to 80°C, stir for 6h, then add 0.9362g (0.008mol) 3-ethynyl aniline (EAL), react with mechanical stirring for 2h, then heat up to 175 ℃ for 12 hours, after the reaction was completed, the reaction mixture was cooled to 40-60 ℃, and poured into the ethanol solution to precipitate a white filamentary polyimide resin, which was crushed, washed 5 times with ethanol...

Embodiment 2

[0045] A kind of preparation method of high-performance colorless transparent polyimide film of the present invention, comprises the following steps:

[0046] (1) Dissolve 17.784g (0.156mol) 1,4-cyclohexanediamine (CHDA) in 335g m-cresol at room temperature and under the protection of nitrogen, mechanically stir until completely dissolved and then add 42.52 (0.04mol) Diamine containing POSS structure, mechanically stirred until completely dissolved, then added 26.8944g (0.12mol) 1,2,4,5-cyclohexane tetra-acid dianhydride (HPMDA) and 23.5376g (0.08mol) 4,4'- Biphenyltetracarboxylic dianhydride (4,4'-BPDA), heat up to 80°C, stir for 6h, then add 0.9362g (0.008mol) 3-ethynylaniline (EAL), mechanically stir for 2h, then heat up to 175°C React for 12 hours. After the reaction is completed, cool the reaction mixture to 40-60°C, and pour it into an ethanol solution to precipitate a white filamentary polyimide resin. After crushing it, wash it with ethanol for 5 times, and finally pla...

Embodiment 3

[0051] A kind of preparation method of high-performance colorless transparent polyimide film of the present invention, comprises the following steps:

[0052](1) Dissolve 15.732g (0.138mol) 1,4-cyclohexanediamine (CHDA) in 391g m-cresol at room temperature and under the protection of nitrogen, mechanically stir until completely dissolved and then add 63.78g (0.06mol) ) contains diamine with POSS structure, stir mechanically until it is completely dissolved, then add 26.8944g (0.12mol) 1,2,4,5-cyclohexane tetra-acid dianhydride (HPMDA) and 23.5376g (0.08mol) 4,4' -Biphenyltetracarboxylic dianhydride (4,4'-BPDA), heat up to 80°C, stir for 6h, then add 0.4681g (0.004mol) 3-ethynylaniline (EAL), mechanically stir for 2h, then heat up to 175 ℃ for 12 hours, after the reaction was completed, the reaction mixture was cooled to 40-60 ℃, and poured into the ethanol solution to precipitate a white filamentary polyimide resin, which was crushed, washed 5 times with ethanol, and finally p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com