A kind of water-based ink and preparation method thereof

A technology of water-based ink and water-based polyurethane, which is applied in inks, household utensils, applications, etc., can solve problems such as complex process, poor emulsion stability, and high cross-linking density, and achieve easy-to-obtain raw materials, strong adhesion, and low cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

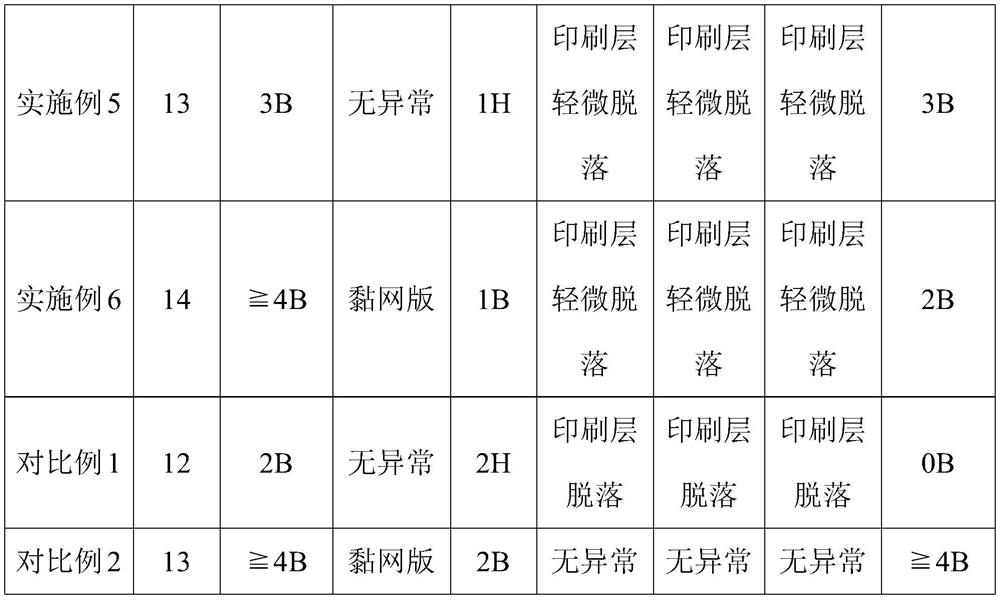

Examples

Embodiment 1

[0071] This embodiment provides a water-based ink and a preparation method thereof.

[0072] The water-based ink comprises the following components in parts by weight: 30 parts of aliphatic polycarbonate-type water-based polyurethane emulsion, 30 parts of aliphatic polyester-type water-based polyurethane emulsion, 1 part of Solsperse 27000 dispersant, 10 parts of carbon black, 20 parts of barium sulfate 10 parts of talcum powder, 0.5 parts of BYK-3565 leveling agent, 0.5 parts of AMP-95pH stabilizer, 0.1 part of KATHON LXE fungicide, 1.5 parts of BYK-015 defoamer and 20 parts of water, among which, aliphatic polycarbonate The mass ratio of the ester type water-based polyurethane emulsion and the aliphatic polyester type water-based polyurethane emulsion is 1:1.

[0073] The preparation method is:

[0074] First, pre-mix aliphatic polycarbonate-type water-based polyurethane emulsion, aliphatic polyester-type water-based polyurethane emulsion, Solsperse 27000 dispersant, carbon...

Embodiment 2

[0076] This embodiment provides a water-based ink and a preparation method thereof.

[0077] The water-based ink comprises the following components in parts by weight: 40 parts of aliphatic polycarbonate-type water-based polyurethane emulsion, 30 parts of aliphatic polyester-type water-based polyurethane emulsion, 2 parts of Solsperse 27000 dispersant, 5 parts of carbon black, 15 parts of barium sulfate 10 parts of talcum powder, 0.1 parts of BYK-3565 leveling agent, 0.1 part of AMP-95pH stabilizer, 0.4 parts of KATHON LXE fungicide, 1 part of BYK-015 defoamer and 20 parts of water, among which, aliphatic polycarbonate The mass ratio of ester type water-based polyurethane emulsion and aliphatic polyester type water-based polyurethane emulsion is 1.33:1.

[0078] The preparation method is:

[0079] First, pre-mix aliphatic polycarbonate-type water-based polyurethane emulsion, aliphatic polyester-type water-based polyurethane emulsion, Solsperse 27000 dispersant, carbon black, ...

Embodiment 3

[0081] This embodiment provides a water-based ink and a preparation method thereof.

[0082] The water-based ink comprises the following components in parts by weight: 20 parts of aliphatic polycarbonate-type water-based polyurethane emulsion, 40 parts of aliphatic polyester-type water-based polyurethane emulsion, 2 parts of Solsperse 27000 dispersant, 20 parts of ultramarine blue, 10 parts of barium sulfate 5 parts of talcum powder, 0.2 parts of BYK-3565 leveling agent, 1 part of AMP-95pH stabilizer, 0.4 parts of KATHON LXE fungicide, 3 parts of BYK-015 defoamer and 22 parts of water, of which aliphatic polycarbonate The mass ratio of the ester type water-based polyurethane emulsion and the aliphatic polyester type water-based polyurethane emulsion is 0.5:1.

[0083] The preparation method is:

[0084] First, pre-mix aliphatic polycarbonate-based water-based polyurethane emulsion, aliphatic polyester-based water-based polyurethane emulsion, Solsperse 27000 dispersant, ultram...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| adhesivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com