A method for radiation reduction and curing of liquid polycarbosilane

A polycarbosilane, liquid technology, applied in the field of polymers, can solve the problems of incomplete hydrogenation and reduction of liquid polycarbosilane, reduce the ceramicization rate of liquid polycarbosilane, and no methyl chloride reduction treatment, etc., to achieve easy industrialization Production, high reproducibility, avoidance of altered effects

Active Publication Date: 2022-05-31

HUBEI UNIV OF SCI & TECH

View PDF3 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, these methods also deviate the silicon-carbon ratio of the cured polymer from 1:1, and introduce a certain amount of free carbon and SiO in the final ceramic product. 2 Such impurities seriously affect the performance of the product

[0005] (2) The hydrogenation reduction reaction of liquid polycarbosilane was not complete during the preparation process, and part of the methyl chloride could not be completely reduced

It can be seen that although the hydrogenation reduction of methyl chloride is not complete, it will not affect the composition of the final product, but it will also reduce the ceramicization rate of the liquid polycarbosilane prepared by the Grignard coupling method.

In the reported studies on the pyrolytic ceramicization of liquid polycarbosilane, no further reduction treatment of methyl chloride has been found, and an effective way to completely remove the methyl chloride contained in liquid polycarbosilane has not yet been found.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

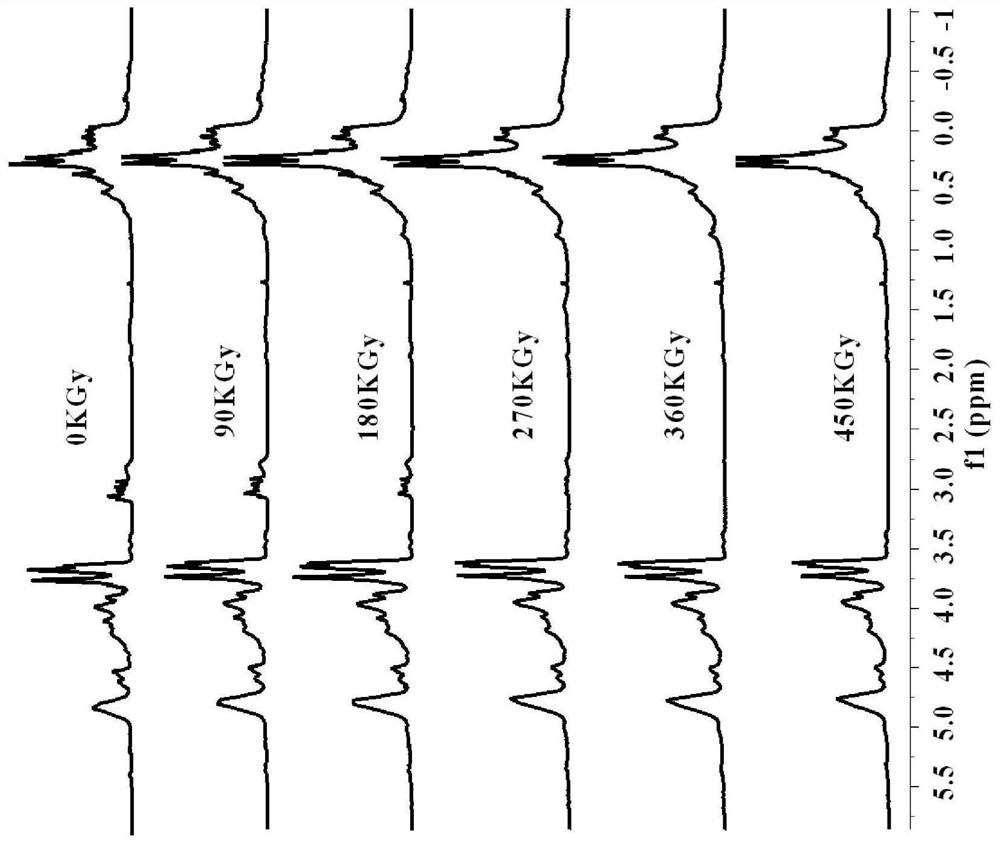

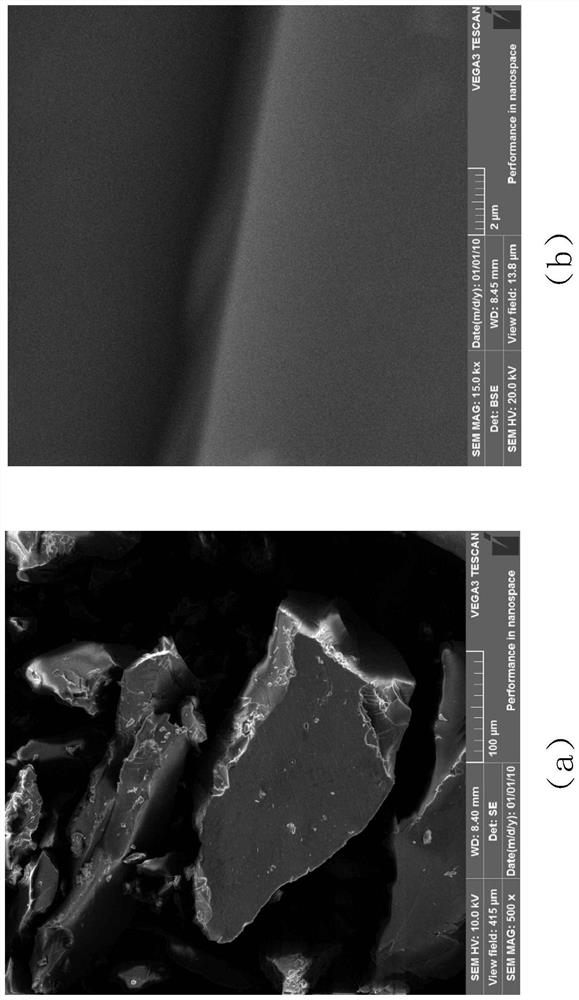

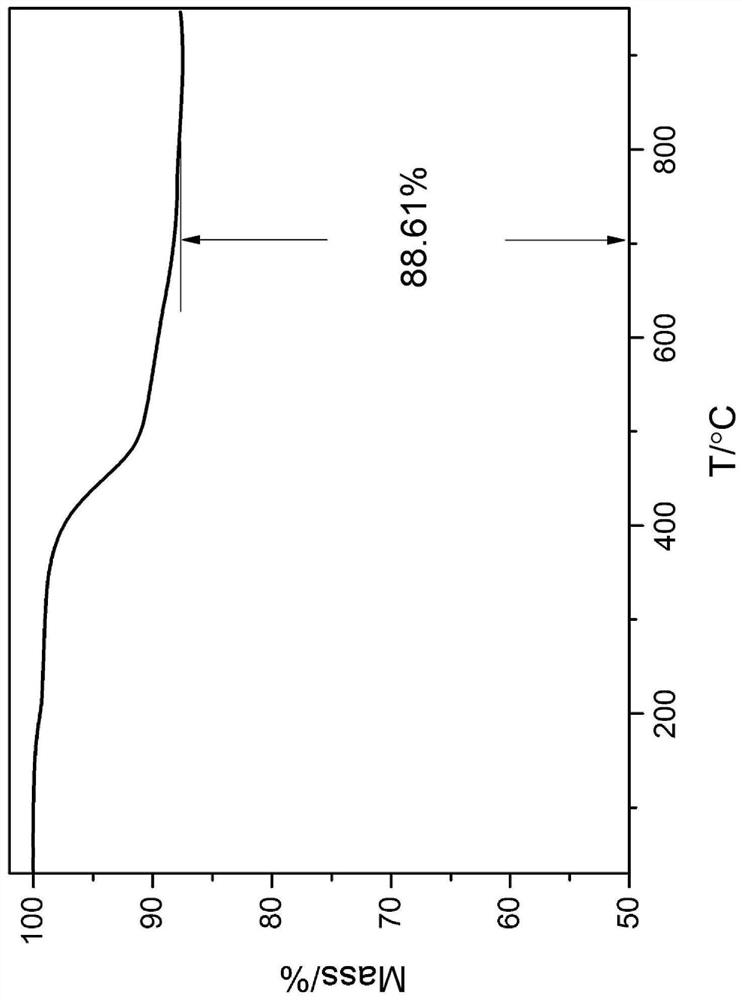

The invention provides a method for radiation reduction and solidification of liquid polycarbosilane, which belongs to the field of macromolecules and the field of inorganic non-metallic ceramics. The invention applies the electron beam radiation technology to the reduction and curing of liquid polycarbosilane, under the electron beam radiation, the liquid polycarbosilane containing chloromethyl groups undergoes a radiation chemical reaction, and the liquid polycarbosilane is realized while chlorine atoms are reduced by hydrogen. Cross-linking and curing of carbosilane, this method can be directly applied to the preparation of silicon carbide ceramic-based materials by impregnation pyrolysis of liquid polycarbosilane, without introducing unsaturated bonds into the molecular chain of liquid polycarbosilane, or in the liquid polycarbosilane precursor The curing of liquid polycarbosilane can be realized by adding crosslinking agent, catalyst and initiator, which not only avoids the change of the silicon-carbon ratio of the polymer precursor during the curing process, but also avoids the introduction of heteroatoms such as platinum, oxygen and nitrogen. , has the advantages of simple operation, easy control, and large-scale production.

Description

A kind of method for radiation reduction and curing of liquid polycarbosilane technical field The invention belongs to polymer field and inorganic non-metallic ceramic technical field, relate to a kind of liquid polycarbosilane Methods of radiation reduction and curing. Background technique Silicon carbide (SiC) is an advanced ceramic material that has received extensive attention, with high strength, low density, high resistance High temperature, anti-oxidation, good compatibility with metals, etc., in the fields of aviation, aerospace, weapons and equipment and civil high temperature resistant parts Has broad application prospects. Among the developed SiC ceramic preparation methods, the polymer impregnation pyrolysis method (PIP) has It has the characteristics of easy molding and processing of polymers, and has become the most suitable for the preparation of SiC films, SiC continuous fibers, SiC matrix composites and adhesives. The most efficient method for com...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C08J3/28C08J3/24C08L83/16C04B35/571C04B35/622

CPCC08J3/28C08J3/24C08G77/60C04B35/571C04B35/622C08J2383/16

Inventor 刘小玲朱晓明余积许云书曹余良谢聪王军涛舒婷胡鹏姬柳迪

Owner HUBEI UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com