A kind of boronization addition curing type phenolic resin and its preparation method and application

An addition curing type, phenolic resin technology, applied in the field of phenolic resin preparation, can solve problems such as difficult to ensure uniform phenolic resin, increase in viscosity of phenolic resin, agglomeration, etc., achieve excellent molding and curing process performance, improve oxidation resistance, excellent Solubility effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

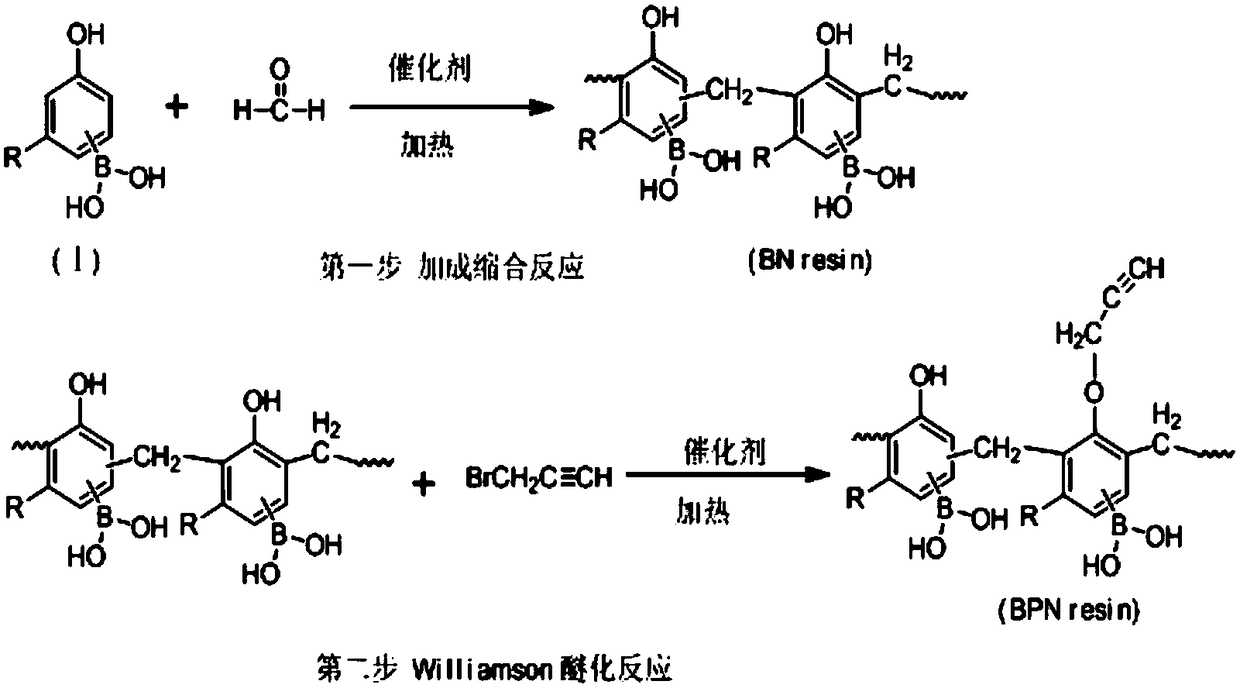

Method used

Image

Examples

Embodiment 1

[0044] Embodiment 1 degree of etherification is the preparation of 20% boronization addition curing type phenolic resin (BPN20):

[0045] (1) Put 33.68 grams of 4-hydroxyphenylboronic acid, 11.20 grams of 37.5% formaldehyde solution, and 100 mL of tetrahydrofuran into a 500 mL four-necked flask equipped with a stirrer, a thermometer, a condenser and a dropping funnel, and stir until the monomer is completely dissolved . While stirring, the temperature was raised, and when the temperature reached 60°C, 0.20 g of concentrated hydrochloric acid was added to the system, and the temperature was continued to rise to 75°C, and the reaction was maintained for 8 hours. After the reaction, remove the solvent by rotary evaporation, then dissolve the resin in an appropriate amount of ethyl acetate, and then add distilled water to wash until the water layer is neutral, then let go of the water layer, and finally remove the ethyl acetate by rotary evaporation to obtain boronized thermoplast...

Embodiment 2

[0047] Embodiment 2 The degree of etherification is the preparation of 40% boronization addition curing type phenolic resin (BPN40):

[0048] (1) 16.80 grams of 3-hydroxyphenylboronic acid, 16.80 grams of 4-hydroxyphenylboronic acid, 12.8 grams of 37.5% formaldehyde solution, and 100 mL of tetrahydrofuran were placed in a 250 mL four-necked flask equipped with a stirrer, a thermometer, a condenser tube and a dropping funnel In, stir until the monomer is completely dissolved. While stirring, the temperature was raised, and when the temperature reached 60°C, 0.50 g of oxalic acid was added to the system, and the temperature was continued to rise to 85°C, and the reaction was kept for 6 hours. After the reaction, remove the solvent by rotary evaporation, then dissolve the resin in an appropriate amount of ethyl acetate, and then add distilled water to wash until the water layer is neutral, then release the water layer, and remove the ethyl acetate by rotary evaporation to obtain ...

Embodiment 3

[0050] Embodiment 3 The degree of etherification is the preparation of boronation addition curing type phenolic resin (BPN60) of 60%

[0051] (1) 16.80 grams of 4-hydroxyphenylboronic acid, 6.80 grams of 37.5% formaldehyde solution, and 50 mL of dioxane are placed in a 100 mL four-necked bottle equipped with a stirrer, a thermometer, a condenser tube and a dropping funnel, and stirred until The monomer is completely dissolved. While stirring, the temperature was raised, and when the temperature reached 60°C, 0.51 g of p-toluenesulfonic acid was added to the system, and the temperature was continued to rise to 90°C, and the reaction was kept for 4 hours. After the reaction, remove the solvent by rotary evaporation, then dissolve the resin in an appropriate amount of ethyl acetate, and then add distilled water to wash until the water layer is neutral, then let go of the water layer, and finally remove the ethyl acetate by rotary evaporation to obtain boronized thermoplastic 16 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com