A kind of environment-friendly low temperature resistant concrete interface treatment agent and preparation method thereof

An interface treatment agent, low temperature resistance technology, applied in the direction of adhesives, adhesive types, adhesive additives, etc., can solve the problems of poor low temperature resistance, insufficient strength of the pulling layer, insufficient adhesion of the treatment agent, etc., to achieve water resistance. The effect of improving, improving ductility, and shortening production man-hours

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

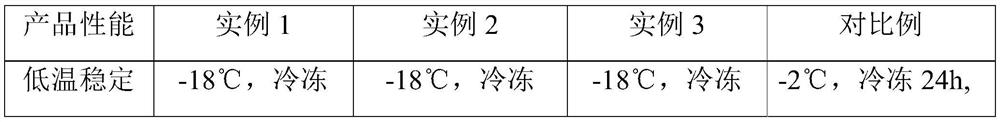

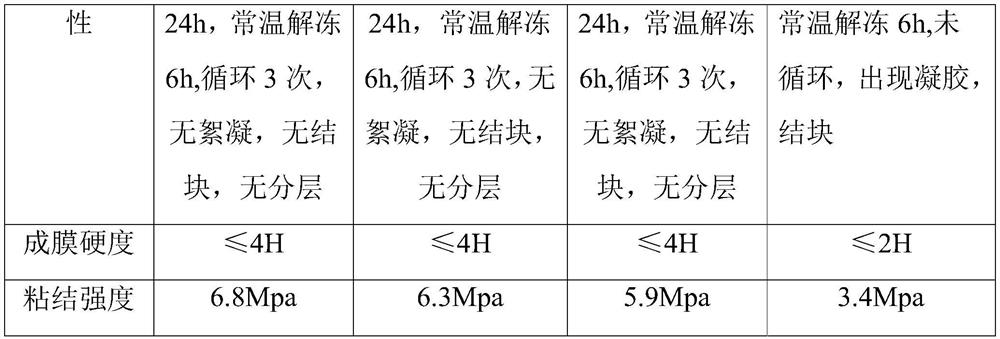

Examples

Embodiment 1

[0021] (1) 60 parts by mass of polyvinyl alcohol and 600 parts by mass of water are placed in a container at 90° C., and after mixing uniformly, 200 parts by mass of water are added to obtain an aqueous solution of polyvinyl alcohol;

[0022] (2) Reduce the temperature of the above polyvinyl alcohol aqueous solution to 76°C, add 2 parts by mass of hydrochloric acid with a concentration of 35wt% and 2 parts by mass of a neutral glutaraldehyde solution with a concentration of 20wt%, and incubate at 76°C for 60 minutes , to obtain the first mixed solution.

[0023] (3) Cool the first mixed solution to 55°C, add 3 parts by mass of AMP-95, adjust the pH to 5, then add 100 parts by mass of EVA emulsion, 5 parts by mass of citric acid, and 10 parts by mass of carbon dioxide Silica sol, 2 parts by mass of defoaming agent and 1 part by mass of preservative are stirred evenly to obtain an environmentally friendly low-temperature resistant concrete interface treatment agent, which is sto...

Embodiment 2

[0026] (1) 50 parts by mass of polyvinyl alcohol and 500 parts by mass of water are placed in a container at 90°C, and after mixing uniformly, 250 parts by mass of water are added to obtain an aqueous solution of polyvinyl alcohol;

[0027] (2) Reduce the temperature of the above polyvinyl alcohol aqueous solution to 76°C, add 1 mass part concentration of 20wt% sulfuric acid and 1 mass part concentration of 20wt% glutaraldehyde neutral aqueous solution, and incubate at 76°C for 60 minutes , to obtain the first mixed solution.

[0028] (3) Cool the first mixed solution to 55°C, add 2 parts by mass of AMP-95, adjust the pH to 5, then add 100 parts by mass of EVA emulsion, 3 parts by mass of citric acid, and 10 parts by mass of carbon dioxide Silica sol, 2 parts by mass of defoaming agent and 2 parts by mass of preservative are stirred evenly to obtain an environmentally friendly low-temperature resistant concrete interface treatment agent, which is stored in a cool place, sealed...

Embodiment 3

[0031] (1) 90 parts by mass of polyvinyl alcohol and 700 parts by mass of water are placed in a container at 90°C, and after mixing uniformly, 150 parts by mass of water are added to obtain an aqueous solution of polyvinyl alcohol;

[0032] (2) The temperature of the above polyvinyl alcohol aqueous solution is reduced to 76°C, and 2 parts by mass of nitric acid with a concentration of 20wt% and 2 parts by mass of a neutral glutaraldehyde solution with a concentration of 20wt% are added successively, and kept at 76°C for 60 minutes , to obtain the first mixed solution.

[0033] (3) Cool the first mixed solution to 55°C, add 5 parts by mass of AMP-95, adjust the pH to 6, then add 150 parts by mass of EVA emulsion, 5 parts by mass of citric acid, and 10 parts by mass of carbon dioxide Silica sol, 3 parts by mass of defoaming agent and 1 part by mass of preservative are stirred evenly to obtain an environmentally friendly low-temperature resistant concrete interface treatment agen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com