Moving bed drying method of materials and device

A drying method and technology of a drying device, which are applied in the directions of drying solid materials, dry cargo handling, heating to dry solid materials, etc., can solve the problems of excessive drying of fine particles, low drying efficiency, and affecting equipment, so as to promote loosening and surface renewal , is conducive to transportation and storage, and accelerates the evaporation of water

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

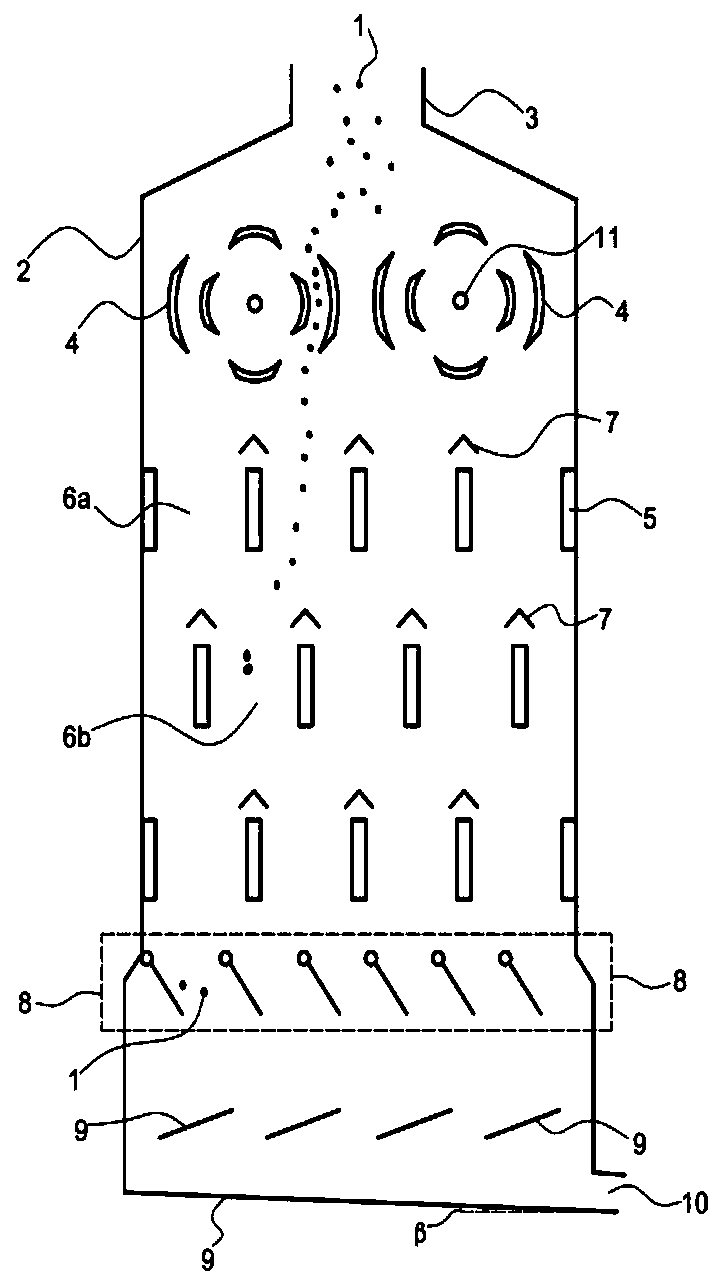

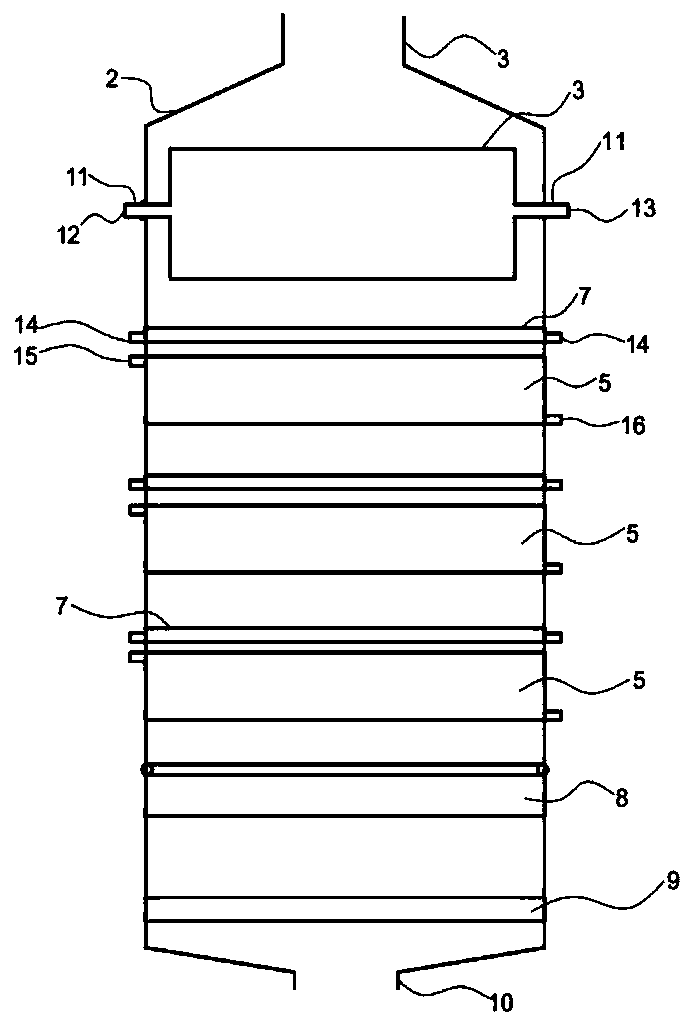

[0049] This example is an embodiment of a coking coal drying method and device for heating the upper moving heating surface and heating the lower fixed heating surface for moving bed coking coal.

[0050] Dryer such as figure 1 and figure 2As shown, the material (coking coal material) 1 enters the dryer from the material inlet 3 provided on the dryer shell 2 and moves from top to bottom by gravity. After being heated by the moving heating surface 4, it enters the fixed heating surface 5 and is further heated. The generated evaporating steam passes through the evaporating steam export channel 7 and is discharged out of the dryer through the evaporating steam outlet 14, the moisture in the coal material drops, and finally flows out of the dryer through the material discharge control mechanism 8 and enters the drying material distribution evaporation mechanism 9, The contained heat promotes the further evaporation of moisture in the coal material, the temperature of the coal ma...

Embodiment 2

[0061] The present embodiment is basically the same as Embodiment 1, except that the dry material is lignite, which is dried to 15% by moisture content of 30%. The heat source used is heat conduction oil, the heat source inlet is 200°C, and the heat source outlet is 150°C.

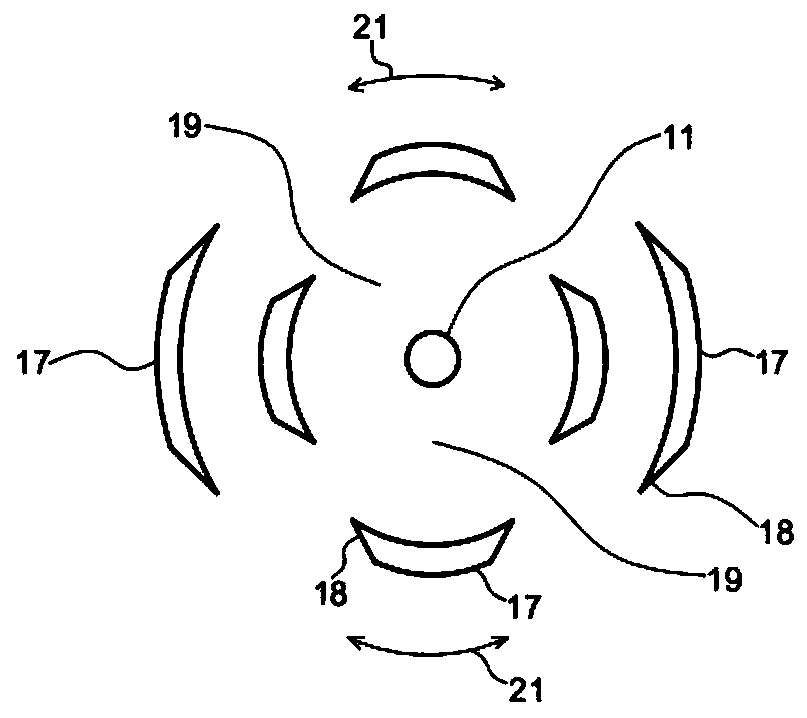

[0062] On the upper part of the dryer, a moving heating surface composed of circular tubes is adopted, and the structure is as follows: Figure 5 and Image 6 shown. The diameter of the tube closest to the rotating shaft is Φ60, the middle is Φ48, and the outer edge is Φ32. The moving heating surface adopts a swing method to move, and the maximum swing angle is 20°. The mobile heating surface adopts the upper and lower units superimposed, which increases the mobile heating area, adapts to the high moisture content of lignite, and is more conducive to preventing bridging. Moreover, an evaporation steam outlet channel is set between the two moving tube heating units to promote the evaporation.

[0063] T...

Embodiment 3

[0066] The present embodiment is basically the same as embodiment 1, except that the drying object is flour, which is dried to 8% by moisture 13%. The moving heating surface is realized by means of rotation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com