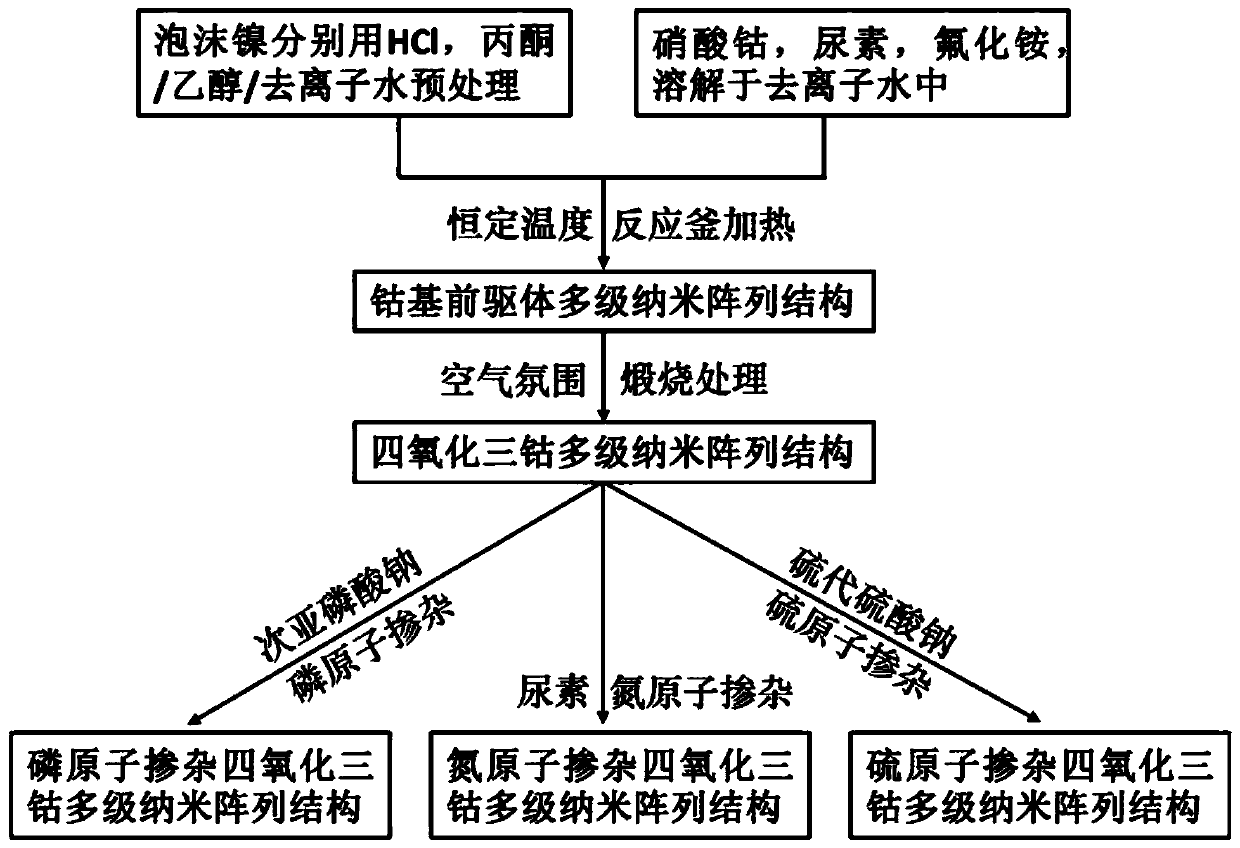

Preparation method of Co3O4 hierarchical-nano structure doped with different anions

A technology of tricobalt tetroxide and nanostructure, which is applied in the field of catalysis, can solve the problems of active site exposure and poor conductivity, and achieve the effects of simple equipment, improvement of poor conductivity, and easy control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

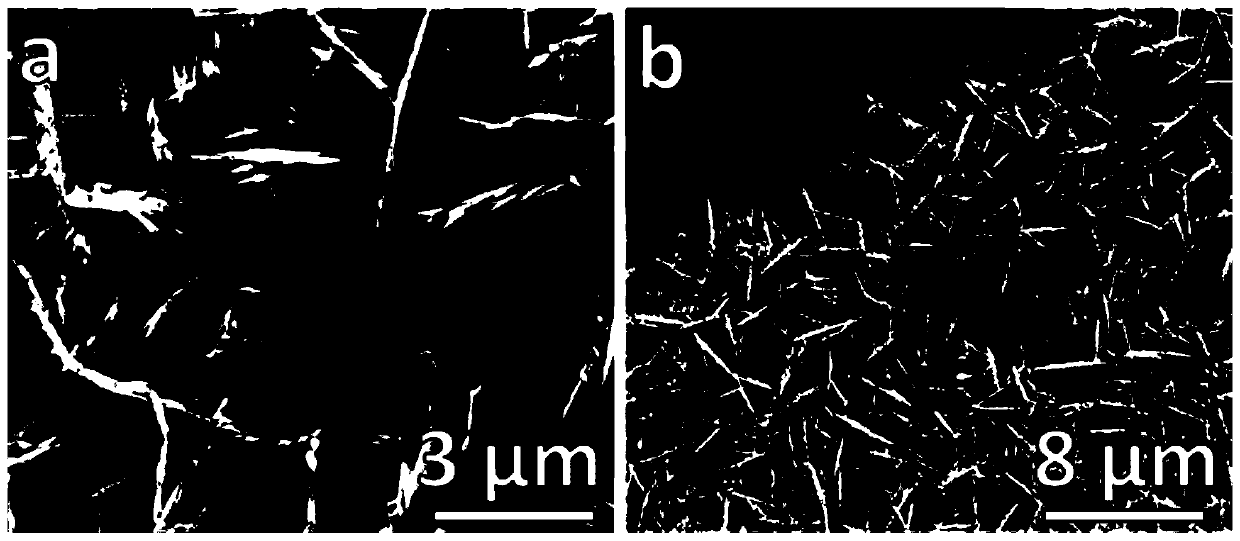

Embodiment 1

[0035] (1) Preparation of multi-level array structure of cobalt-based precursor: use nickel foam (2cm×5cm×1.0mm) as the substrate, soak in 5% hydrochloric acid for 20min to remove the oxide layer on the surface, and then use acetone and ethanol and deionized water (DI) in turn, and dried naturally for later use. Weigh 1.5g of cobalt nitrate hexahydrate, 1.0g of urea, and 0.3g of ammonium fluoride, disperse them in deionized water, transfer them to a 100ml reactor, and perform ultrasonic dispersion treatment. Below the surface, make it fully contact with the reaction solution. After the shell is sealed, transfer it to an oven, keep the temperature at 100°C, keep it for 6 hours, and cool down naturally. The nickel foam with cobalt-based precursor grown on the surface is taken out from the inner lining of the reactor, rinsed repeatedly with deionized water and ethanol, transferred to a vacuum oven for drying at 60°C, and the multi-level cobalt-based precursor grown on the surface...

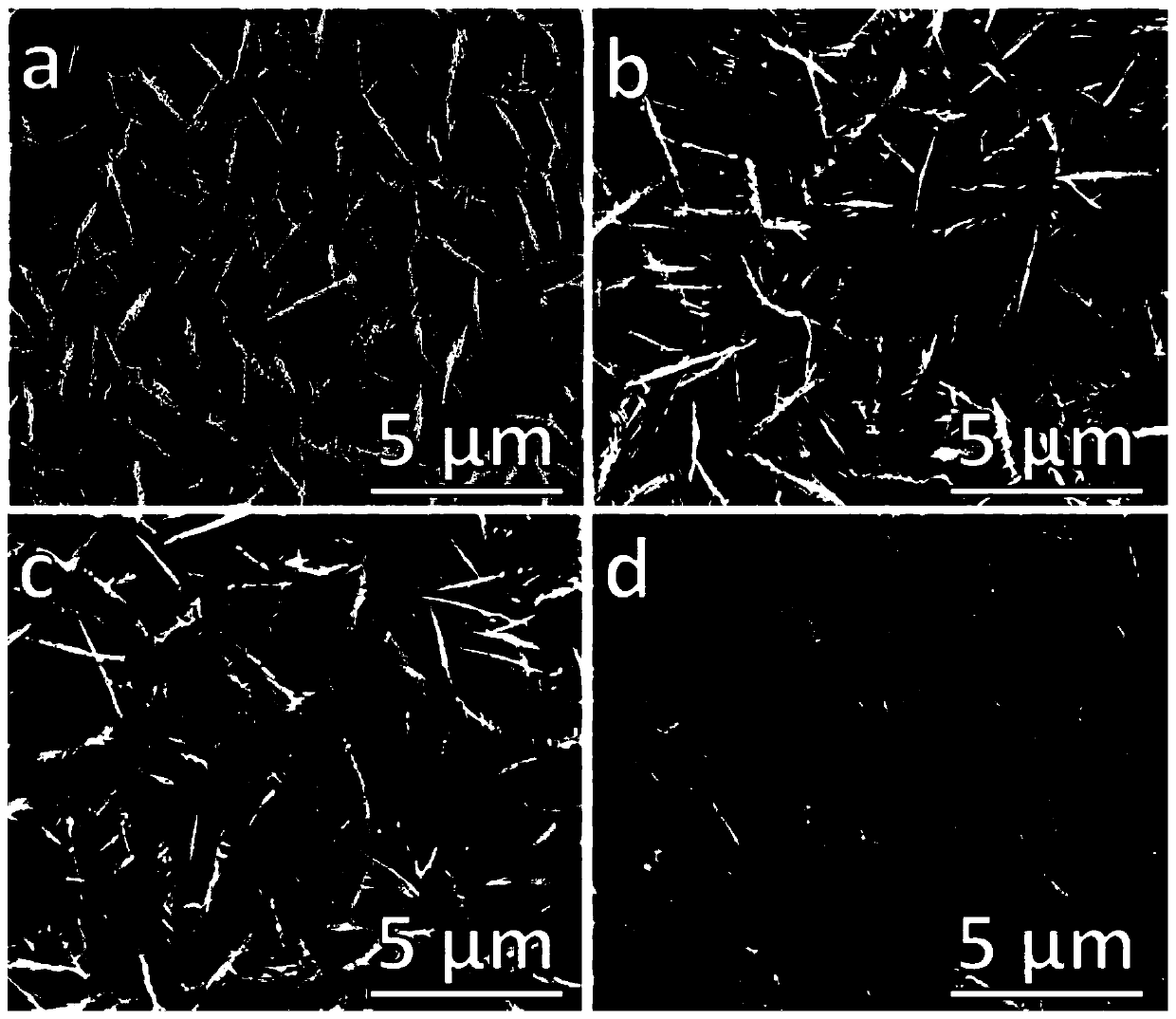

Embodiment 2

[0039] (1) Preparation of multi-level array structure of cobalt-based precursor: use nickel foam (2cm×5cm×1.5mm) as the substrate, soak in 5% hydrochloric acid for 20min to remove the oxide layer on the surface, and then use acetone and ethanol and deionized water (DI) in turn, and dried naturally for later use. Weigh 2.0g of cobalt nitrate hexahydrate, 2.0g of urea, and 0.4g of ammonium fluoride, disperse them in deionized water, transfer them to a 100ml reactor, and perform ultrasonic dispersion treatment, then transfer the processed nickel foam to the reactor, immerse in the liquid Below the surface, make it fully contact with the reaction solution. After the shell is sealed, transfer it to a vacuum oven, keep the temperature at 120 ° C, keep it for 8 hours, and cool down naturally. The nickel foam with cobalt-based precursor grown on the surface is taken out from the inner lining of the reactor, rinsed repeatedly with deionized water and ethanol, transferred to a vacuum ov...

Embodiment 3

[0043] (1) Preparation of cobalt-based precursor multi-level array structure: use nickel foam (2cm×5cm×1.7mm) as the substrate, soak in 5% hydrochloric acid for 20min to remove the oxide layer on the surface, and then use acetone, ethanol and deionized water (DI) in turn, and dried naturally for later use. Weigh 2.5g of cobalt nitrate hexahydrate, 1.5g of urea, and 0.6g of ammonium fluoride, disperse them in deionized water, transfer them to a 100ml reactor, and perform ultrasonic dispersion treatment, then transfer the processed nickel foam to the reactor, immerse in the liquid Below the surface, make it fully contact with the reaction solution. After the shell is packaged, transfer it to an oven, keep the temperature at 150°C, keep it for 10h, and cool down naturally. The nickel foam with cobalt-based precursor grown on the surface is taken out from the inner lining of the reactor, rinsed repeatedly with deionized water and ethanol, transferred to a vacuum oven for drying at...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com