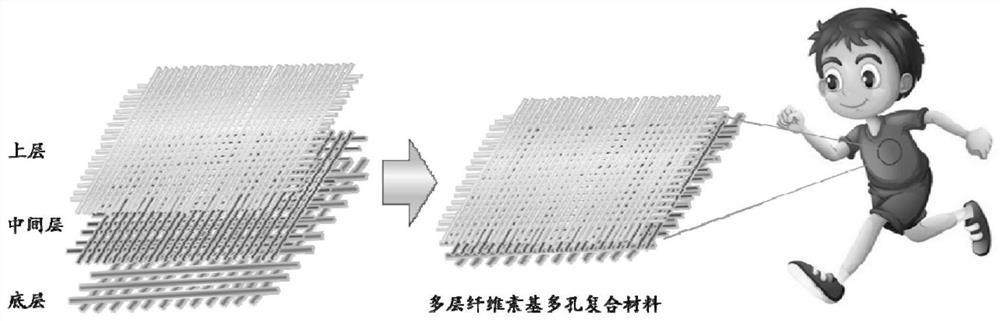

A waterproof and moisture-permeable functional cellulose-based porous composite material and its preparation and application

A technology of porous materials and composite materials, which is applied to functional porous composite materials and the fields of their preparation and application, can solve the problems of difficult recycling, non-degradability, and high production costs of products, and achieve enhanced water and gas transport capacity, optimal flexibility and mechanical properties. , good flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

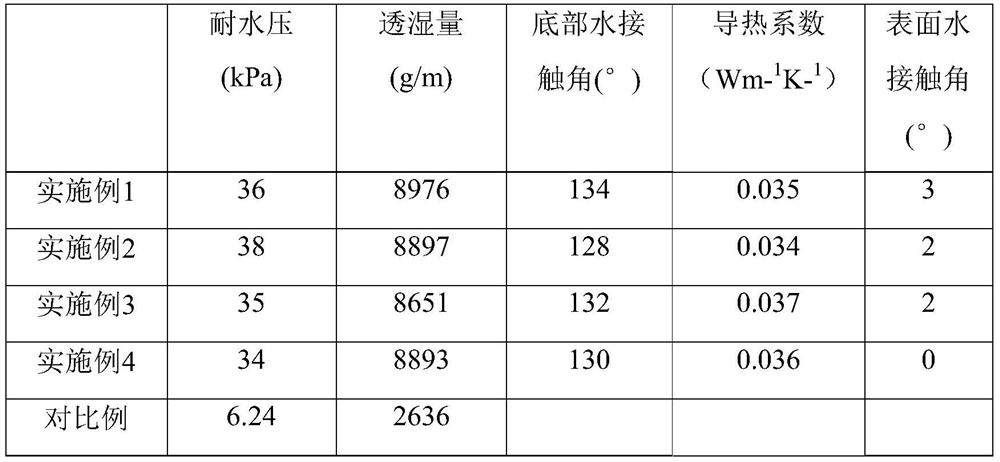

Embodiment 1

[0040] First prepare a single-layer hydrophobic cellulose porous material. The specific preparation process is: take a cellulose nanowire suspension with a solid content of 1wt% (Tianjin Wood Fairy Co., Ltd.), the length of the cellulose nanowire is 1 μm, and the diameter is 20nm, and then add formazan Trimethoxysilane (Shanghai Sinopharm Chemical Reagent Co., Ltd., CAS: 1185-55-3), wherein the mass ratio of cellulose nanowires to methyltrimethoxysilane is 1:0.5. After stirring at room temperature for 2 hours, the mixed solution was frozen with liquid nitrogen for 10 minutes and then transferred to a freeze dryer. The freeze-drying temperature was -50°C and the freeze-drying time was 30 hours. ℃ oven for 1h. Immerse the prepared cellulose porous material in a polyurethane solution with a solid content of 4wt% (Jining Baiyi Chemical Co., Ltd., HK3100), wherein the mass proportion of the cellulose porous material is 10wt%, and the mass proportion of the polyurethane impregnation...

Embodiment 2

[0044] First prepare a single-layer hydrophobic cellulose porous material, the specific preparation process is: take 2wt% solid content of cellulose nanowire suspension (Tianjin Wood Fairy Co., Ltd.), the cellulose nanowire length is 20 μm, the diameter is 40nm, and then add formazan Methyldiethoxysilane, wherein the mass ratio of cellulose nanowires and methyldiethoxysilane is 1:1. After stirring for 4 hours at room temperature, the mixed solution was frozen with liquid nitrogen for 10 minutes and then transferred to a freeze dryer. The freeze-drying temperature was -50°C and the freeze-drying time was 40 hours. ℃ oven placed 2h. Immerse the prepared cellulose porous material in a polyurethane solution with a solid content of 8wt% (Jining Baiyi Chemical Co., Ltd., HK3100), wherein the mass proportion of the cellulose porous material is 20wt%, and the mass proportion of the polyurethane impregnation solution is 78wt%. , while adding 2wt% mass fraction of the three-proof finis...

Embodiment 3

[0048] First prepare a single-layer hydrophobic cellulose porous material, the specific preparation process is: take 1.2wt% solid content of cellulose nanowire suspension (Tianjin Wood Fairy Co., Ltd.), the cellulose nanowire length is 10 μm, the diameter is 30nm, and then add Dimethyldivinylsilane, wherein the mass ratio of cellulose nanowires to dimethyldivinylsilane is 1:0.6. After stirring at room temperature for 2 hours, the mixed solution was frozen with liquid nitrogen for 10 minutes and then transferred to a freeze-drying machine. The freeze-drying temperature was -50°C and the freeze-drying time was 35 hours. ℃ oven for 1h. Immerse the prepared cellulose porous material in a polyurethane solution with a solid content of 5wt% (Jining Baiyi Chemical Co., Ltd., HK3100), wherein the mass proportion of the cellulose porous material is 15wt%, and the mass proportion of the polyurethane impregnation solution is 81wt%. , while adding 4wt% mass fraction of the three-proof fin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com