Method of Bayer process alumina factory dissolution and evaporation combined process

A combined process, Bayer process technology, applied in chemical instruments and methods, preparation of aluminum compounds, alkali metal aluminate/alumina/aluminum hydroxide, etc. Use and other issues to achieve the effects of reducing equipment investment, saving steam consumption, and fully utilizing heat

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

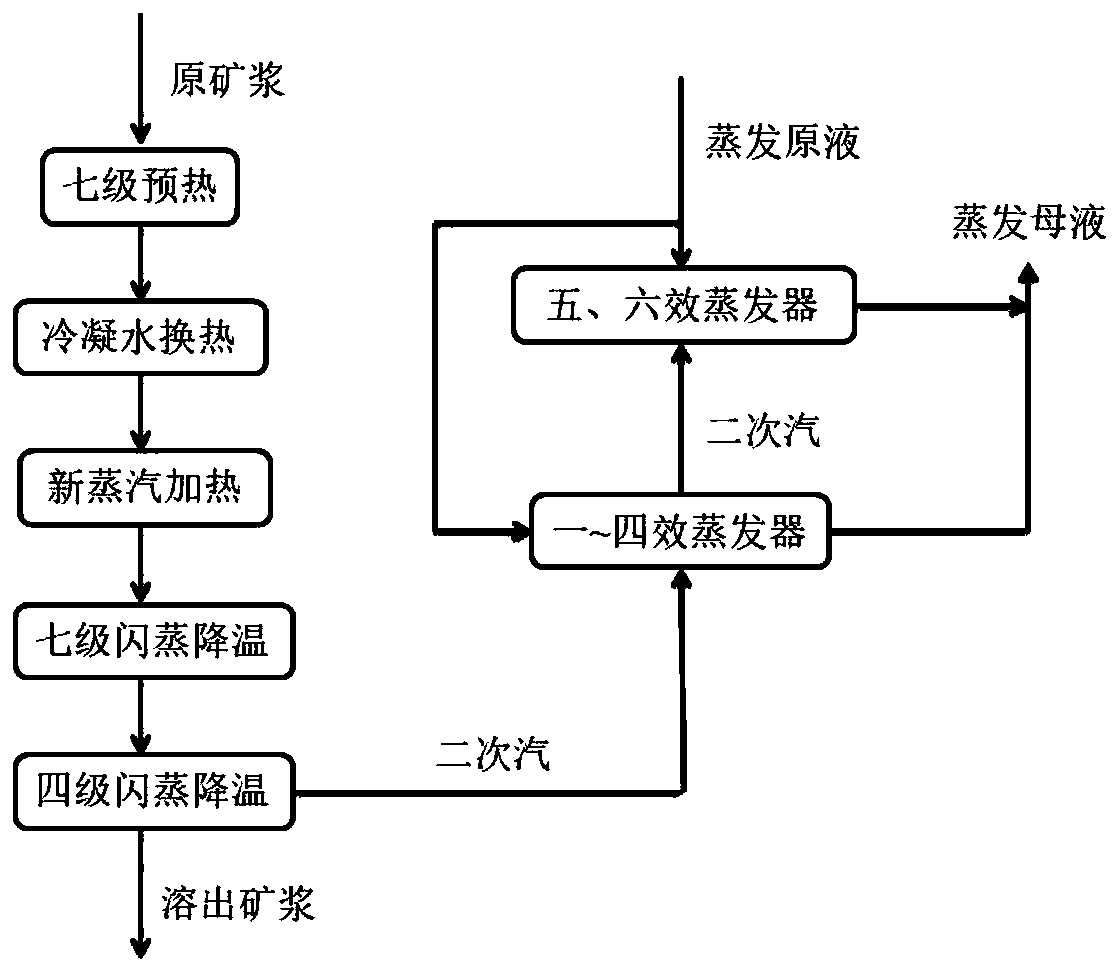

[0015] The dissolution process is equipped with seven-stage preheating sleeves, first-stage fresh steam condensate heating sleeves, and first-stage fresh steam heating sleeves. The stripped slurry is heated to the stripping temperature through the casing, and then enters the thermal retention reaction tube. After the reaction is completed, the eleven-stage flash evaporation is performed to cool down. The first seven-stage flash secondary steam is used to heat the dissolved slurry, and the last four-stage flash secondary steam Enter the first, second, third, and four-effect evaporator in sequence. The evaporator is still fed with four or six effects, and the distribution ratio is 60% for four effects and 40% for six effects. The solution entering the six-effect evaporator is discharged after passing through the six-effect and five-effect evaporator in sequence. The solution entering the four-effect evaporator passes through four, three, two, one-effect evaporators and three-sta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com