Method for treating sludge and deodorizing method

A technology for sludge and wastewater treatment, which is applied in the field of sludge treatment and low-energy sludge treatment, and can solve the problems of biological filter clogging and difficult operation and management.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

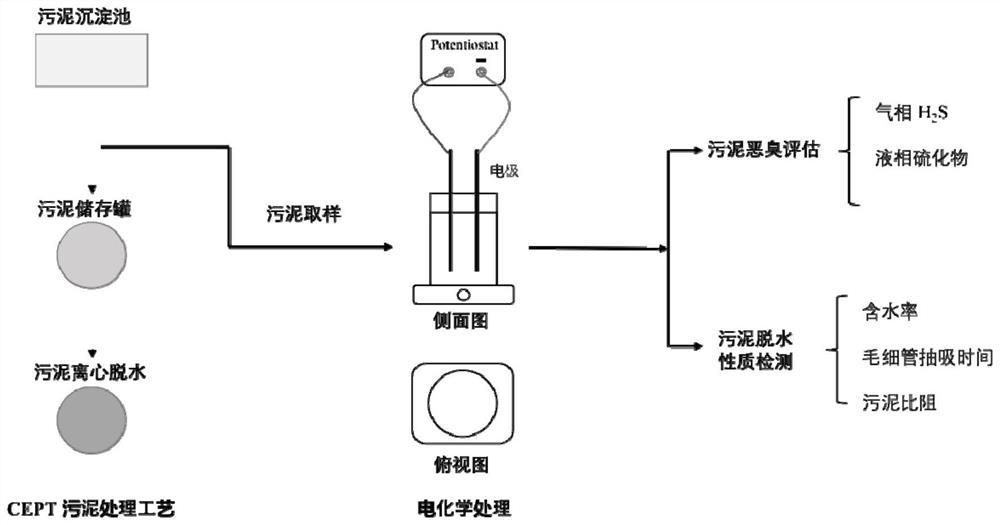

[0093] Example 1: Using CEPT sludge from Stonecutters Island Sewage Treatment Works in Hong Kong

[0094] Collect CEPT sludge (eg. figure 1 shown). The MLSS of the sludge was 25 g / L.

[0095] The CEPT sludge was added to the plexiglass electrolytic cell, and a carbon fiber brush electrode (fiber diameter 5-7μm, length 5cm; cylindrical brush body diameter 10cm, length 15cm, specific surface area 8000m) was used. 2 / m 3 ), treated the sludge for 5, 10 and 15 minutes at a voltage of 10V under the conditions of normal temperature and pressure.

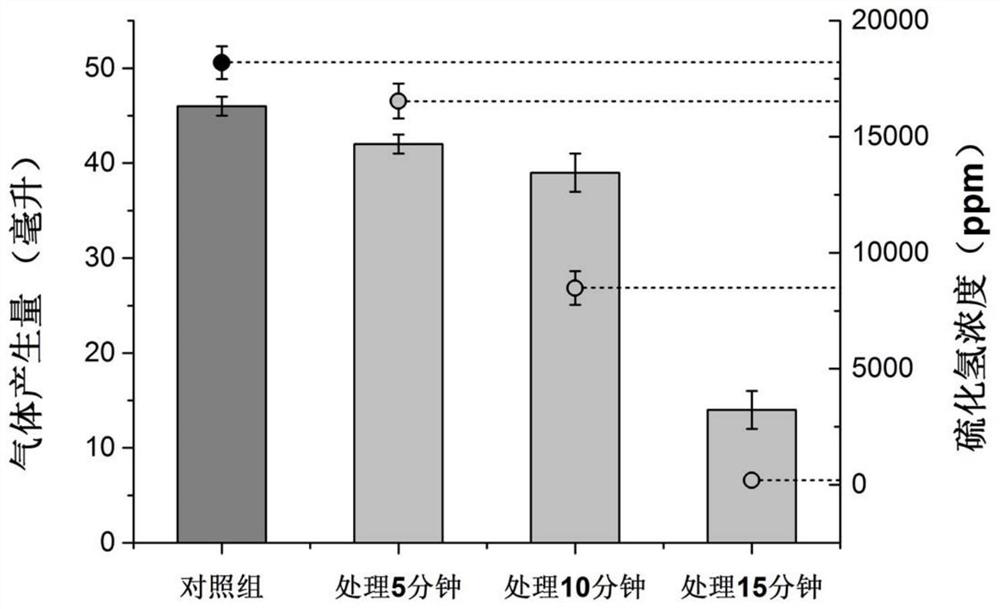

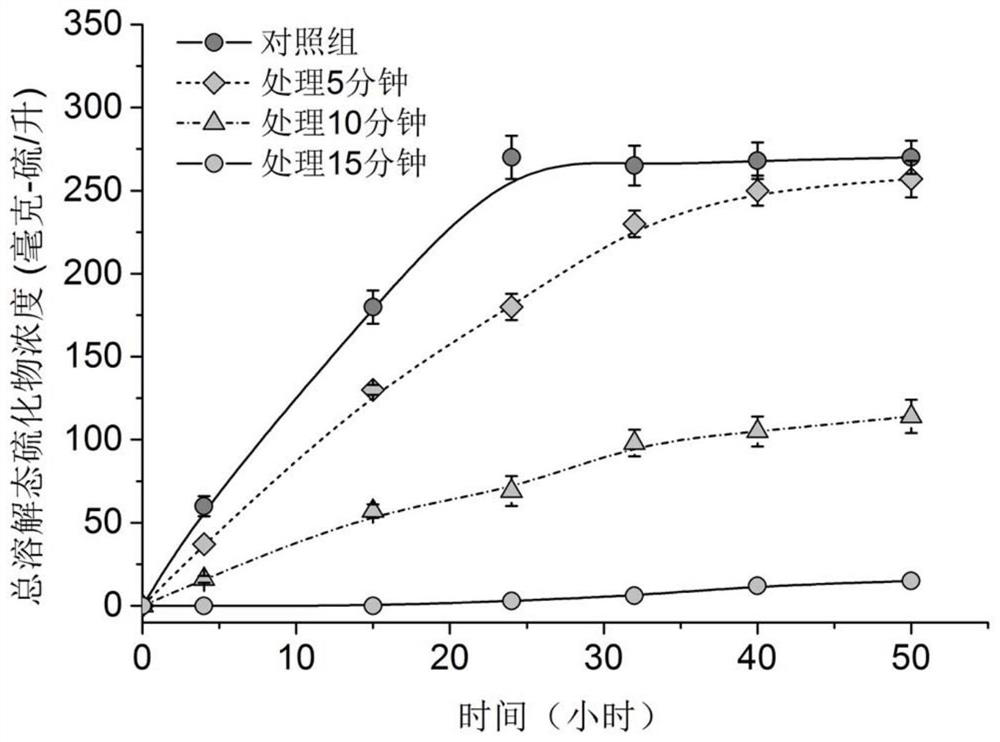

[0096] Untreated 90 ml CEPT sludge and treated CEPT sludge were collected and transferred to 125 ml serum bottles for malodour analysis. During the experiment, serum bottles were stored at a constant temperature of 38°C with agitation of 750rpm. The result is as figure 2 and image 3 shown.

[0097] The sludge moisture content, capillary suction time (CST), and sludge specific resistance (SRF) were investigated to evaluate the slu...

example 2- example 8

[0100] Example 2-Example 8 were basically carried out according to the method of Example 1, except that the electrochemical treatment conditions and the type of odor source were changed according to Table 1 below. The sludge dewatering rate and hydrogen sulfide removal rate were then evaluated according to the method of Example 1.

[0101] Table 1

[0102]

[0103]

[0104]

[0105] In short, the method does not need to add chemicals, and does not generate secondary pollutants. This method can simultaneously control the sludge H 2 The production of S, and the improvement of sludge dewaterability. The electrochemical treatment adopted in this method can realize the efficient deodorization of sludge (99% H 2 S removal rate) and dehydration (88%). The traditional sludge treatment process improves sludge dewaterability and odor control by adding different methods such as flocculants and oxidants, resulting in higher treatment costs, tedious operation and maintenance a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com