Coagulation method and equipment for halogenated butyl rubber

A technology of halogenated butyl rubber and coagulation method, which is applied in the field of butyl rubber synthesis, which can solve the problems of increasing the load of the first coagulation tank to remove hexane, consuming large and low-pressure steam, and poor flexibility of the device, so as to reduce steam consumption , Reduction of circulating water consumption, and the effect of process optimization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

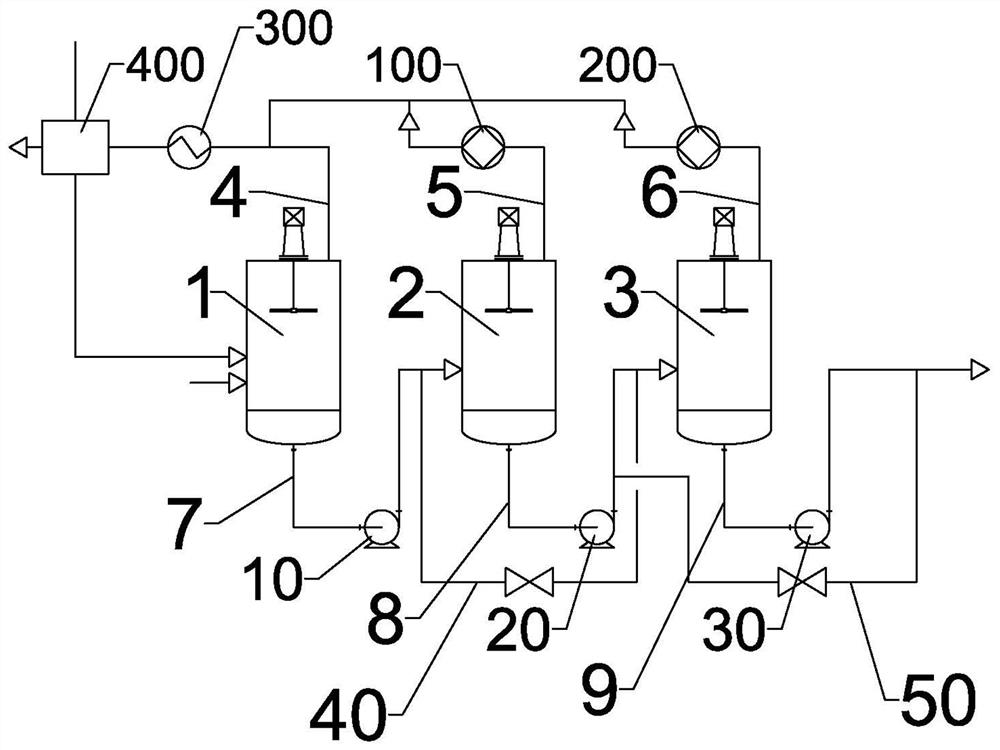

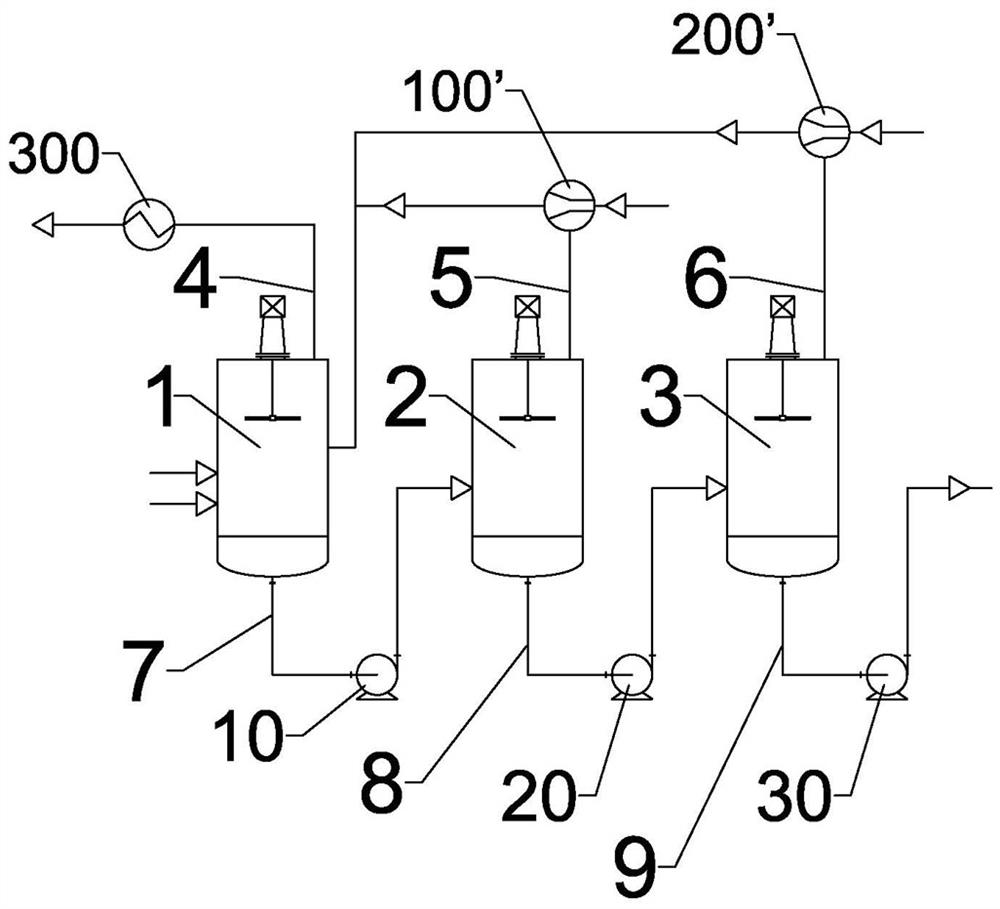

[0031] Such as figure 1 As shown, a device suitable for coagulation of halobutyl rubber. Including the first coagulation tank 1, the second coagulation tank 2, the third coagulation tank 3, the first delivery pump 10, the second delivery pump 20, the third delivery pump 30, the first water ring vacuum pump 100, and the second water ring vacuum pump 200 , condenser 300 and heat pump system 400; the top outlet of the first condensation kettle 1 is connected with the inlet of the condenser 300 through the first gas phase pipe 4; the bottom outlet of the first condensation kettle 1 is connected with the first colloidal particle water pipe 7 The feed port of the second condensation kettle 2 is connected; the top outlet of the second condensation kettle 2 is connected with the inlet of the condenser 300 through the second gas phase pipe 5; the bottom outlet of the second condensation kettle 2 is connected through the second colloidal water pipe 8 is connected with the feed port of ...

Embodiment 2

[0035]The equipment used in this embodiment is the same as that in Embodiment 1, but the control process is different.

[0036] Specifically, the only difference is that this embodiment adopts a two-pot differential pressure process.

[0037] More specifically: in this embodiment, the material inlet of the second coagulation tank 2 is closed, and the valve on the first regulating pipeline 40 is opened. In this way, the colloidal water pumped out from the first coagulation tank 1 directly enters the third coagulation tank 3 for operation.

Embodiment 3

[0039] The equipment used in this embodiment is the same as that in Embodiment 1, but the control process is different.

[0040] Specifically, the only difference is that this embodiment adopts a two-pot differential pressure process.

[0041] More specifically: in this embodiment, the material inlet of the third coagulation tank 3 is closed, and the valve on the second regulating pipeline 50 is opened. In this way, the colloidal water pumped out from the second coagulation tank 2 directly enters the solid-liquid separation device for operation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com