High-specific capacitance electrode foil electrolyte, composition thereof and preparation method of electrode foil

A technology of electrode foil and electrolyte, which is applied in the direction of electrolytic capacitors, electrolytic coatings, surface reaction electrolytic coatings, etc., can solve the problems of unable to meet market demand and large capacity loss, reduce leakage, increase specific volume and life, and can highly operable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] The preparation method of electrode foil comprises the following steps:

[0022] Step 1, cut the aluminum foil into a width of 6.5*6.5m 2 aluminum foil samples;

[0023] Step 2, boil the aluminum foil sample in high temperature water for 10-15 minutes to obtain the intermediate sample;

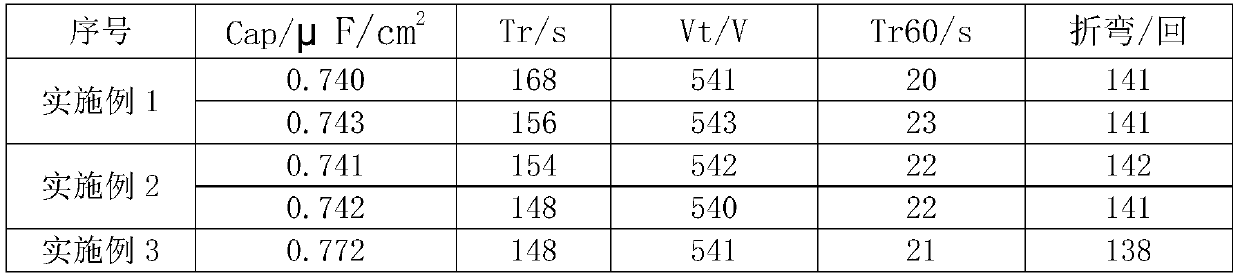

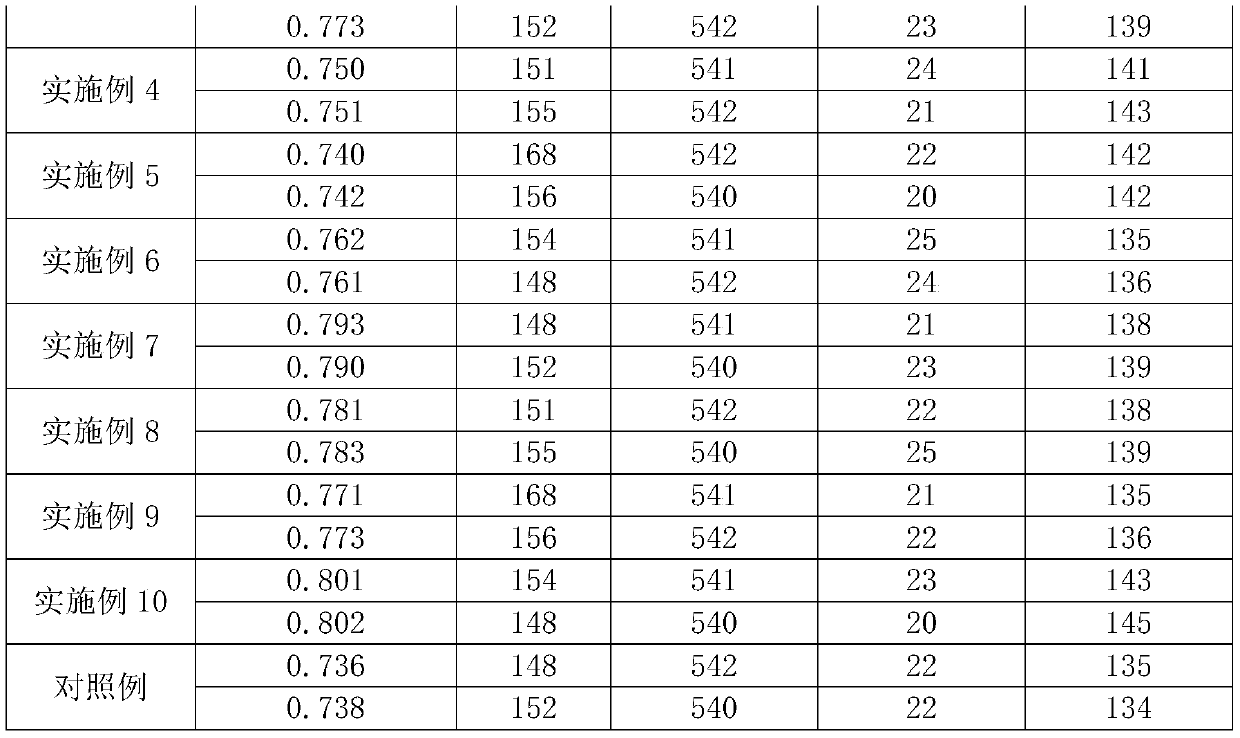

[0024] Step 3, the intermediate sample is placed in the electrolyte (the concentration of each component in the electrolyte is as follows: boric acid concentration is 20g / L, tartaric acid concentration is 0.5g / L, ammonium pentaborate concentration is 1g / L, ammonium dihydrogen phosphate Concentration is 0.5g / L), at a current density of 80mA / cm 2 Under the action of a high current, anodic oxidation, heat treatment, intermediate treatment, secondary anodic oxidation and post-treatment are carried out in sequence, and finally the electrode foil is obtained. The performance indicators of the electrode foil are as follows: the final withstand voltage is 541-543V, and the capacity is 0.740-...

Embodiment 2

[0026] The preparation method of electrode foil comprises the following steps:

[0027] Step 1, cut the aluminum foil into a width of 6.5*6.5m 2 aluminum foil samples;

[0028] Step 2, boil the aluminum foil sample in high temperature water for 10-15 minutes to obtain the intermediate sample;

[0029] Step 3, the intermediate sample is placed in the electrolyte (the concentration of each component in the electrolyte is as follows: boric acid concentration is 20g / L, tartaric acid concentration is 0.5g / L, ammonium pentaborate concentration is 5g / L, ammonium dihydrogen phosphate Concentration is 0.5g / L), at a current density of 80mA / cm 2 Under the action of a high current, anodic oxidation, heat treatment, intermediate treatment, secondary anodic oxidation and post-treatment are carried out in sequence, and finally the electrode foil is obtained. The performance indicators of the electrode foil are as follows: the final withstand voltage is 540-542V, and the capacity is 0.741-...

Embodiment 3

[0031] The preparation method of electrode foil comprises the following steps:

[0032] Step 1, cut the aluminum foil into a width of 6.5*6.5m 2 aluminum foil samples;

[0033] Step 2: Boil in high temperature water for 10-15 minutes to obtain intermediate samples;

[0034] Step 3, the intermediate sample is placed in the electrolyte (the concentration of each component in the electrolyte is as follows: boric acid concentration is 20g / L, tartaric acid concentration is 2.5g / L, ammonium pentaborate concentration is 1g / L, ammonium dihydrogen phosphate Concentration is 0.5g / L), at a current density of 80mA / cm 2 Under the action of a high current, anodic oxidation, heat treatment, intermediate treatment, secondary anodic oxidation and post-treatment are carried out in sequence, and finally the electrode foil is obtained. The performance indicators of the electrode foil are as follows: the final withstand voltage is 541-542V, and the capacity is 0.772-0.773μF / cm 2 , The mechanic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Pressure value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com