Quality monitoring controller for bonding equipment and lumped control method thereof

A technology for quality monitoring and control methods, applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve the problem of inability to meet precision and high-speed bonding requirements, aggravate the performance gap of the whole machine process system, and difficult to meet high-speed wire bonding, etc. problems, to achieve the effect of low system development difficulty, shortened development cycle, cost-effective and reliable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

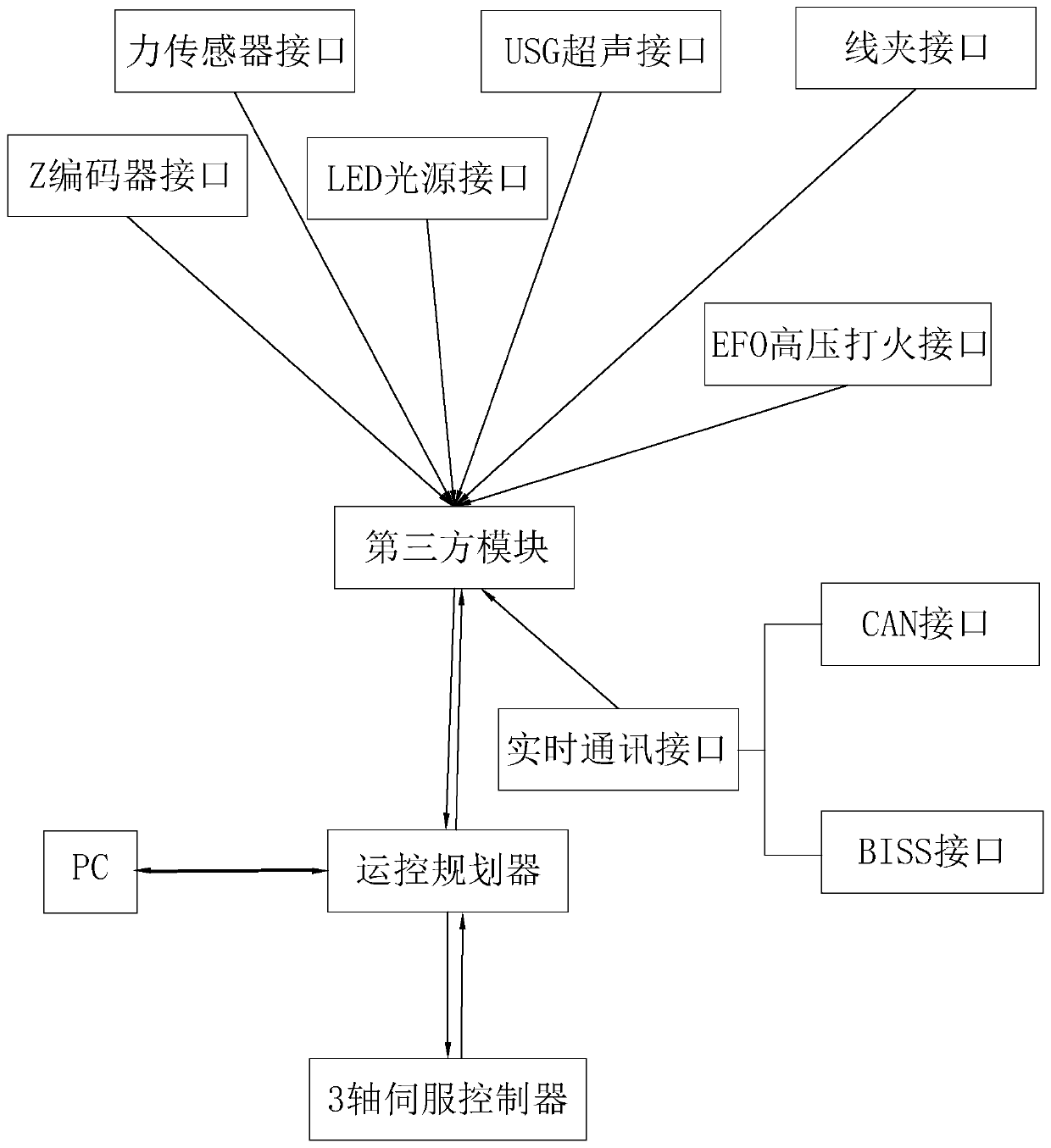

[0040] Embodiment 1 is a quality monitoring controller for bonding equipment disclosed by the present invention, referring to figure 1 , including third-party slave modules for high-speed cooperation between various process modules. The third-party modules include microcontrollers, and the model of the microcontroller is embedded Cortex-M4. The third-party slave station module communicates with the operation control planner in real-time EtherCAT, the operation control planner communicates with the servo controller in real-time EtherCAT, and the operation control planner communicates with the PC through the Ethernet network port.

[0041] The third-party slave station module has built-in FS force sensor interface, Z encoder interface, USG ultrasonic interface, EFO high-voltage ignition interface, WCL clamp interface, LED light source interface and real-time communication interface to obtain process data of each process module, so that High-speed cooperation between various proc...

Embodiment 2

[0055] Embodiment 2, a kind of lumped control method of the quality monitoring controller that bonding equipment is used, refer to figure 1 , including the third-party slave station module to obtain the process data of each process module through the FS force sensor interface, Z encoder interface, USG ultrasonic interface, EFO high-voltage ignition interface, WCL clamp interface and LED light source interface, and then through the COE protocol to collect The process data of each process module is converted into real-time control parameters and mapped into the operation control planner, and the data in the operation control planner is updated in real time.

[0056] The process data of each process module is transmitted to the third-party slave station module through the CAN interface or BISS interface, and the third-party slave station module converts the process data of various process modules into real-time control parameters through the COE protocol and maps them to the opera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com