Tensile crease-resistant synthetic leather fabric for belt and preparation method thereof

A synthetic leather and fabric technology, applied in the field of synthetic leather, can solve the problems of inability to restore automatically, harsh storage conditions, and synthetic leather is not resistant to folding, etc., and achieve the effect of improving physical and chemical properties, solving the problem of broken leather, and soft hand feeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

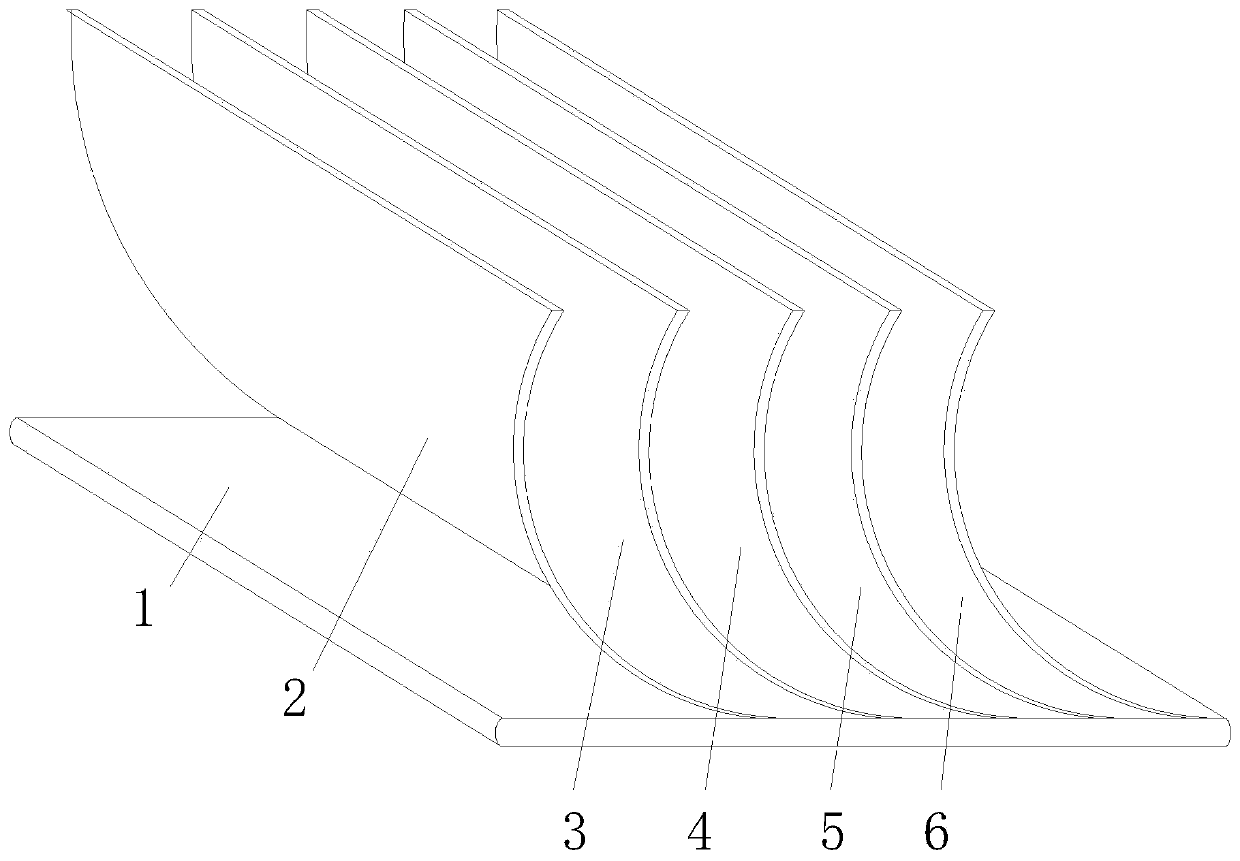

[0036] see figure 1 , the tensile and wrinkle-resistant synthetic leather fabric for belts provided by the invention comprises a base cloth layer 1, an anti-wrinkle layer 2, a tough slurry layer 3, a composite slurry layer 4, a surface layer 5 and a high specular layer 6, the base cloth layer 1 and the The anti-wrinkle layer 2 is formed by mixed weaving, wherein the base fabric layer 1 is used as the warp yarn, and the anti-wrinkle layer 2 is used as the weft yarn to interweave each other according to the plain weave. Evenly coated on the surface of the tough slurry 3 , the surface layer 5 is evenly coated on the surface of the composite slurry 4 , and the high specular layer 6 is evenly sprayed on the surface of the surface layer 5 .

[0037] The base fabric layer 1 is composed of weft-lined yarns, warp-lined yarns and two sets of diagonally-lined yarns. Each set of lined yarns is parallel and straightly arranged to form a yarn layer. The weft-inserted yarn is made of polyes...

Embodiment 2

[0070] The tensile and wrinkle-resistant synthetic leather fabric for belts provided by the embodiments of the present invention and its preparation method are basically the same as in Example 1, except that:

[0071] The anti-wrinkle layer 2 is composed of shape-memory polyurethane fiber and organic antibacterial agent through spinning technology, which has both shape memory performance and antibacterial function. The organic antibacterial agent is made of the following components in weight percentage: 15% polyol, 3% acid anhydride, 9% polyamine, 35% guanidine hydrochloride and 45% low molecular organosiloxane.

[0072] Toughness slurry 3 is made of the following components by weight percentage: 60% thermoplastic resin slurry, 5% polysiloxane, 10% inhibitor, 20% catalyst, 5% crosslinking agent.

[0073] Composite slurry 4 is made of the following components by weight percentage: 30% polyvinyl chloride, 5% tri-n-butyl phosphate, 6% hydrofluoric acid, 2% brucite powder, 1% ethy...

Embodiment 3

[0077] The tensile and wrinkle-resistant synthetic leather fabric for belts provided by the embodiments of the present invention and its preparation method are basically the same as those in Examples 1 and 2, except that:

[0078] The anti-wrinkle layer 2 is formed by compounding shape-memory polyurethane fiber and organic antibacterial agent through spinning technology, which has both shape-memory performance and antibacterial function. The organic antibacterial agent is made of the following components by weight percentage: 18% polyol, 5% acid anhydride, 13% polyamine, 37% guanidine hydrochloride and 46.5% low molecular organosiloxane.

[0079] Toughness slurry 3 is made of the following components in weight percentage: 61% thermoplastic resin slurry, 6% polysiloxane, 12% inhibitor, 22% catalyst, 6.5% crosslinking agent.

[0080] Composite slurry 4 is made of the following components by weight percentage: 34% polyvinyl chloride, 7.5% tri-n-butyl phosphate, 9.5% hydrofluoric ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com