A kind of preparation method of terbutaline sulfate

A technology of terbutaline sulfate and acid binding agent is applied in the field of preparation of terbutaline sulfate, can solve the problems of expensive raw materials, long reaction steps, complicated operation, etc., and avoids high-risk and highly toxic reagents, reaction Mild conditions, long solution steps and low yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

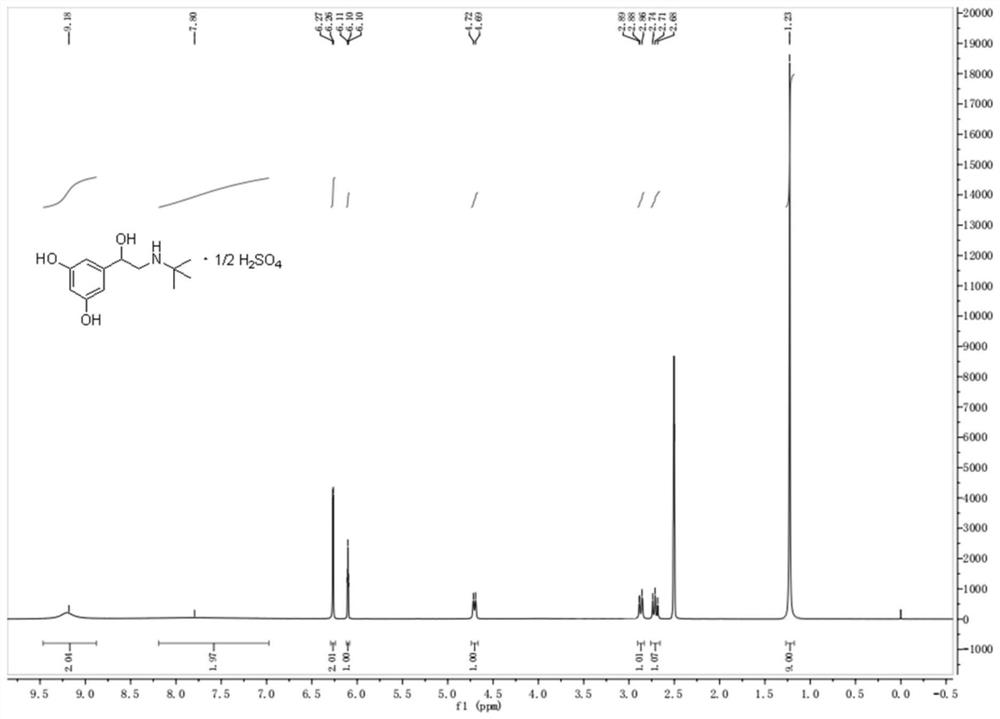

[0033] A preparation method of terbutaline sulfate, specifically comprising:

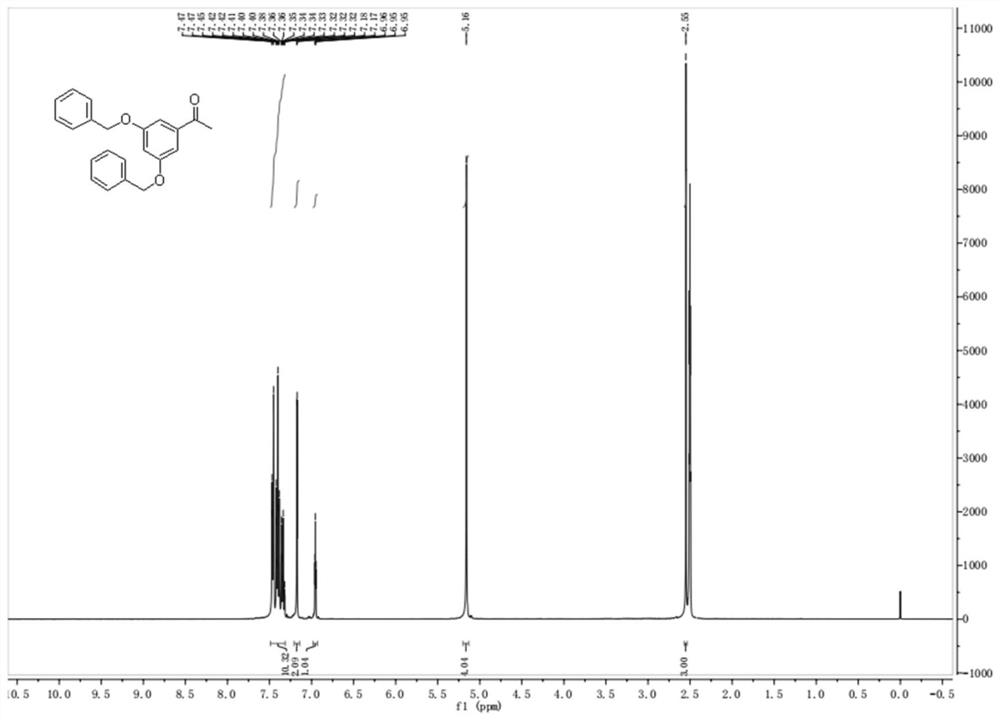

[0034] (1) Preparation of 3,5-dibenzyloxyacetophenone

[0035] At room temperature, 100.0g (657.25mmol) of 3,5-dihydroxyacetophenone, 227.1g (1.64 mol) of anhydrous potassium carbonate, 1L of acetone and 174.7g (1.38 mol) of benzyl chloride were added successively in the reaction vessel. , and reacted at 50°C for 6h. The reaction solution was cooled to room temperature, filtered with suction, the filter cake was washed with acetone (2×100 mL), the combined filtrates were evaporated under reduced pressure to remove acetone, and the residue was recrystallized from methanol to obtain an off-white solid, namely 3,5-dibenzyloxybenzene 175.0 g of ethyl ketone, yield 80%.

[0036] 1 H NMR (300MHz, DMSO-d6): δ=7.32-7.47 (m, 10H), 7.18 (d, J=1.8Hz, 2H), 6.96 (t, J=1.8Hz, 1H), 5.16 (s, 4H) ),2.55(s,3H).

[0037] (2) Preparation of 3,5-dibenzyloxyacetophenone aldehyde

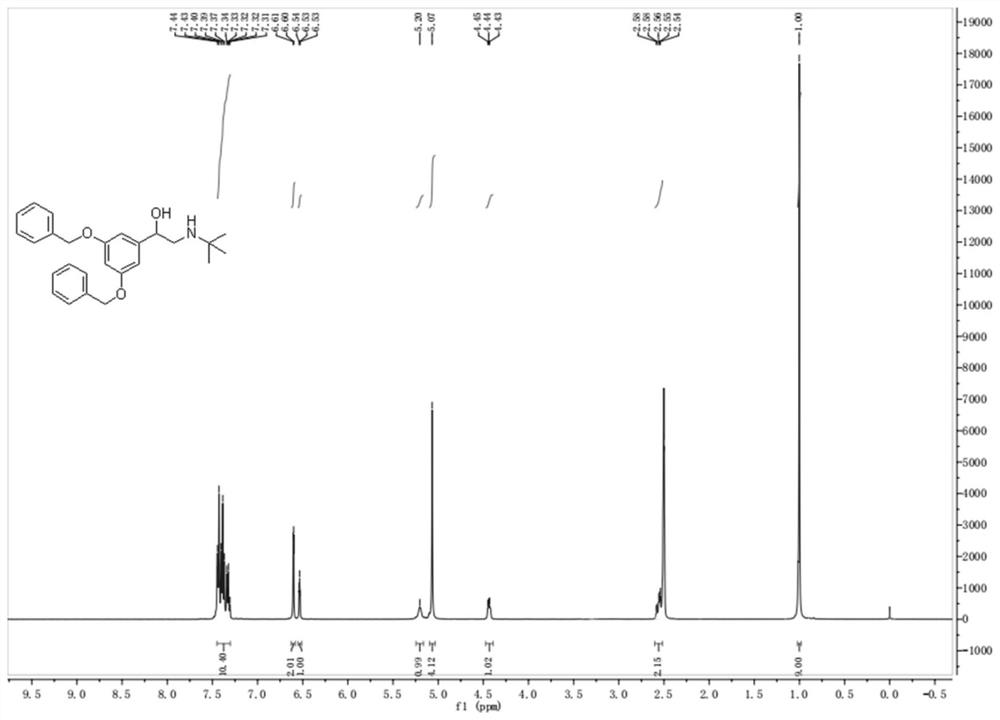

[0038]At room temperature, 100.0 g...

Embodiment 2

[0048] A preparation method of terbutaline sulfate, specifically comprising:

[0049] (1) Preparation of 3,5-dibenzyloxyacetophenone

[0050] At room temperature, 150.0g (985.88mmol) of 3,5-dihydroxyacetophenone, 313.4g (2.27 mol) of anhydrous potassium carbonate, 1L of acetone and 262.1g (2.07 mol) of benzyl chloride were successively added to the reaction vessel. , and reacted at 60°C for 4h. The reaction solution was cooled to room temperature, filtered with suction, the filter cake was washed with acetone (2×100 mL), the combined filtrates were evaporated under reduced pressure to remove acetone, and the residue was recrystallized from methanol to obtain an off-white solid, namely 3,5-dibenzyloxybenzene 268.7 g of ethyl ketone, yield 82%.

[0051] 1 H NMR (300MHz, DMSO-d6): δ=7.32-7.47 (m, 10H), 7.18 (d, J=1.8Hz, 2H), 6.96 (t, J=1.8Hz, 1H), 5.16 (s, 4H) ),2.55(s,3H).

[0052] (2) Preparation of 3,5-dibenzyloxyacetophenone aldehyde

[0053] At room temperature, 150.0 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com