Patents

Literature

39results about How to "No high temperature and high pressure reaction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Brivaracetam and preparation method of intermediate thereof

The invention discloses a preparation method of a brivaracetam intermediate shown in B-VI. The preparation method comprises the following steps of dissolving B-IV and R-phenylethylamine into a solvent, crystallizing, filtering, and recrystallizing, so as to obtain B-V; then, converting into B-VI. The preparation method has the advantages that a chiral chromatographic column separation isomer is not needed in the preparation process, and only the simple steps of extraction, washing, drying, concentration and the like are performed, so as to separate effective ingredients; the separation process is simple, and the production cost of brivaracetam is greatly reduced. A formula is shown in the description.

Owner:宜宾市南溪区红光制药有限公司

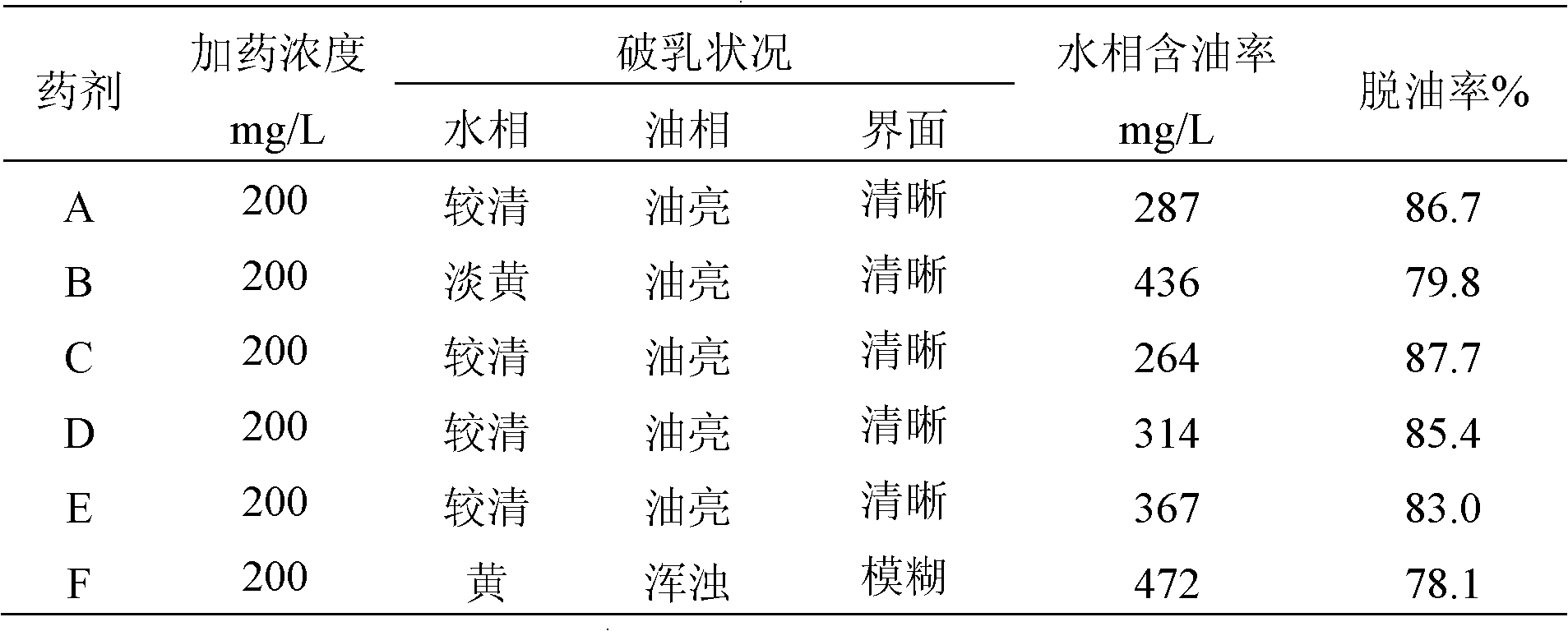

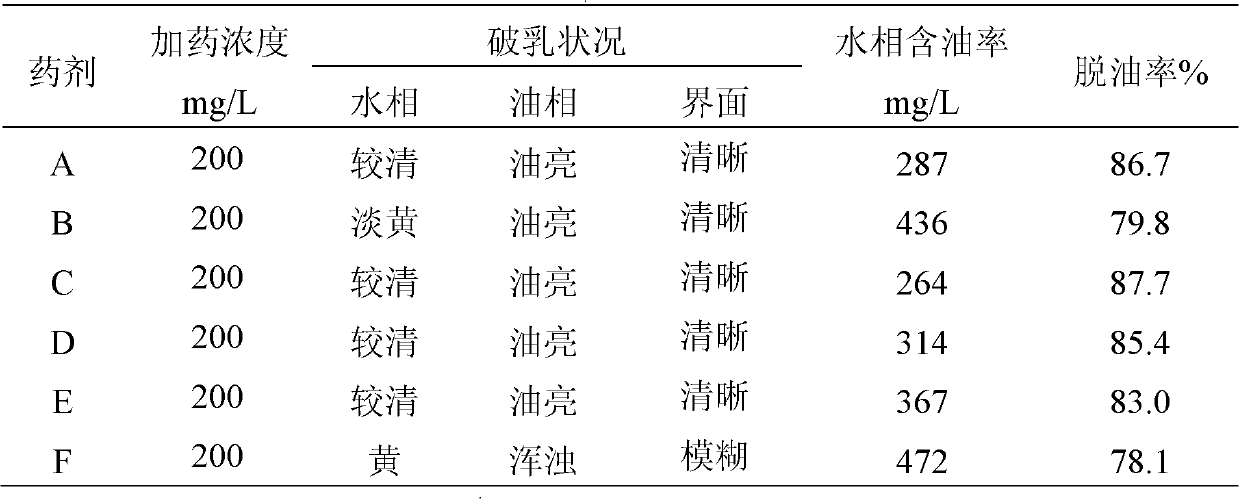

Reverse demulsifier and its preparation method

ActiveCN102559246AGood demulsification effectLow equipment requirementsDewatering/demulsification with chemical meansEthylenediamineHigh pressure

The invention discloses a reverse demulsifier and its preparation method. The method comprises allowing reaction between methyl acrylate and ethylenediamine to obtain linear polyamidoamine, and allowing reaction between the linear polyamidoamine and epoxy chloropropane to obtain quaternary ammonium salt of linear polyamidoamine; allowing free-radical polymerization between polyoxyethylene nonylphenyl ether acrylate, acryloyloxyethyltrimethylammonium chloride and acrylamide in the present of an initiator and a terminator to obtain amphipathic cationic polymer; and mixing the quaternary ammonium salt of linear polyamidoamine, the amphipathic cationic polymer, a cationic surfactant and water to obtain the reverse demulsifier. The inventive reverse demulsifier has good demulsification effect on oil-in-water emulsion produced from oil field, and is suitable for chemical flooding produced fluid; and the inventive preparation method has low requirement for equipment, and is free of high-temperature high-pressure reaction.

Owner:CHINA NAT OFFSHORE OIL CORP +1

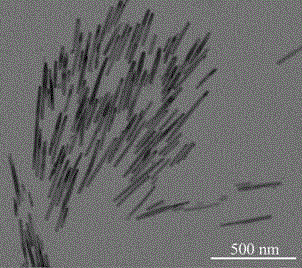

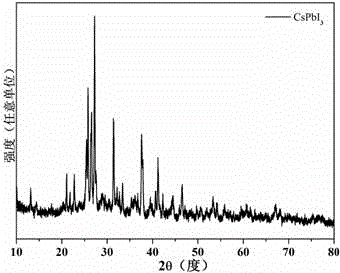

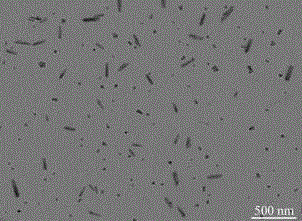

Method for preparing caesium-lead halide nanorod and product obtained through method

The invention discloses a method for preparing a caesium-lead halide nanorod and the product obtained through the method. The method includes the steps that lead halide and octadecene are mixed to be stirred for 0.5-1.5 hours, and then oleylamine and oleic acid are added into a mixture in sequence to be stirred till the lead halide is completely dissolved; the lead halide is heated to 130-200 DEG C after being completely dissolved, then a caesium precursor solution is slowly poured into liquor, and caesium-lead halide is prepared through a thermal insulation reaction; after the reaction is completed, reaction liquid is subjected to centrifuging, separating and washing, and accordingly the caesium-lead halide nanorod is obtained. According to the method, the caesium-lead halide nanorod is synthesized in an organic phase system, the reaction temperature is 130-200 DEG C, and the method belongs to a low-temperature organic phase synthesis method; the method is easy to operate, high-temperature and high-pressure reactions can be avoided, safety is achieved, the size of the nanorod can be regulated and controlled through the reaction condition, the obtained caesium-lead halide nanorod is even in shape, good in crystal form, and wide in application prospect in the fields of solar cells, LEDs, panel display and the like.

Owner:UNIV OF JINAN

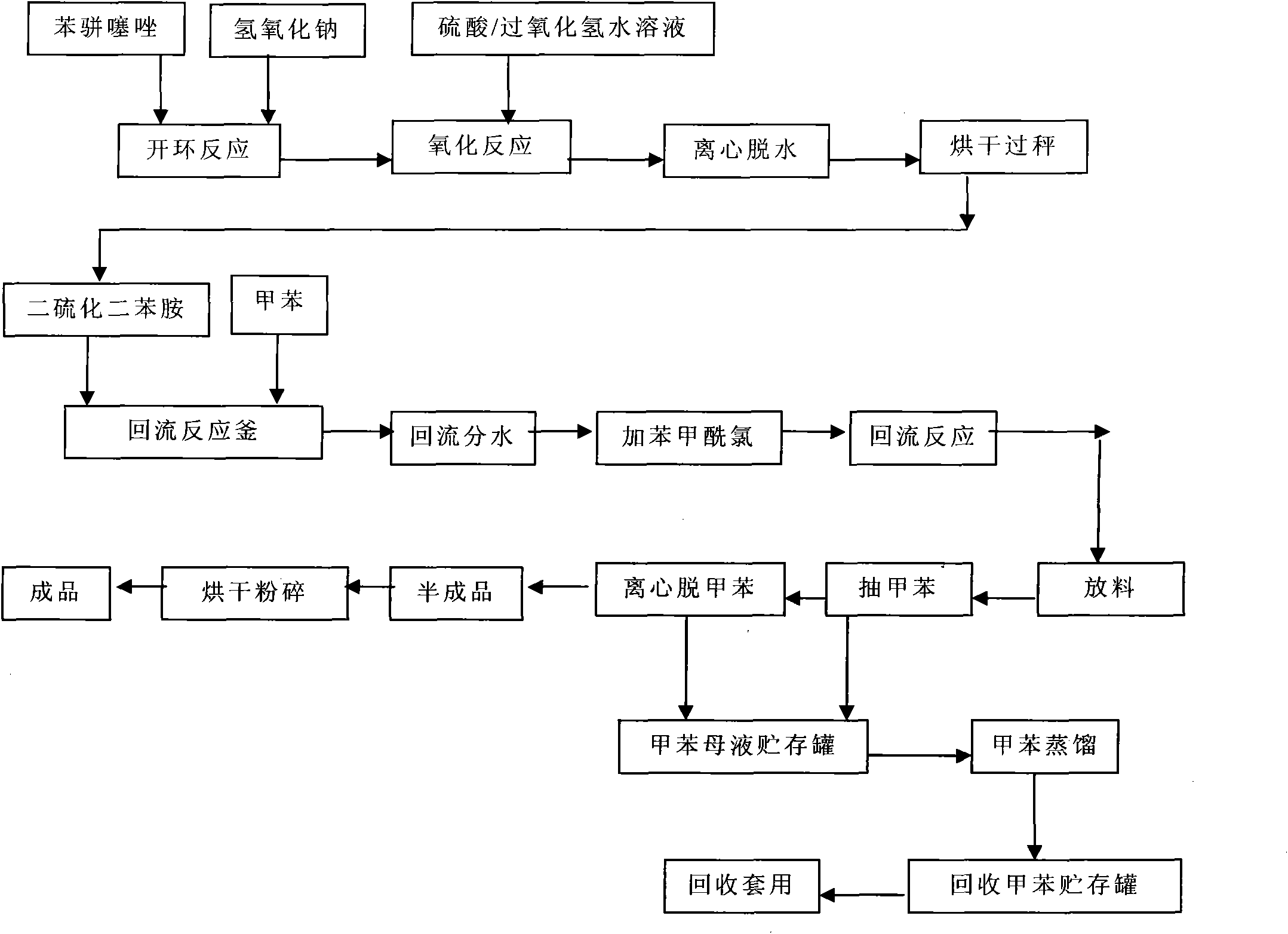

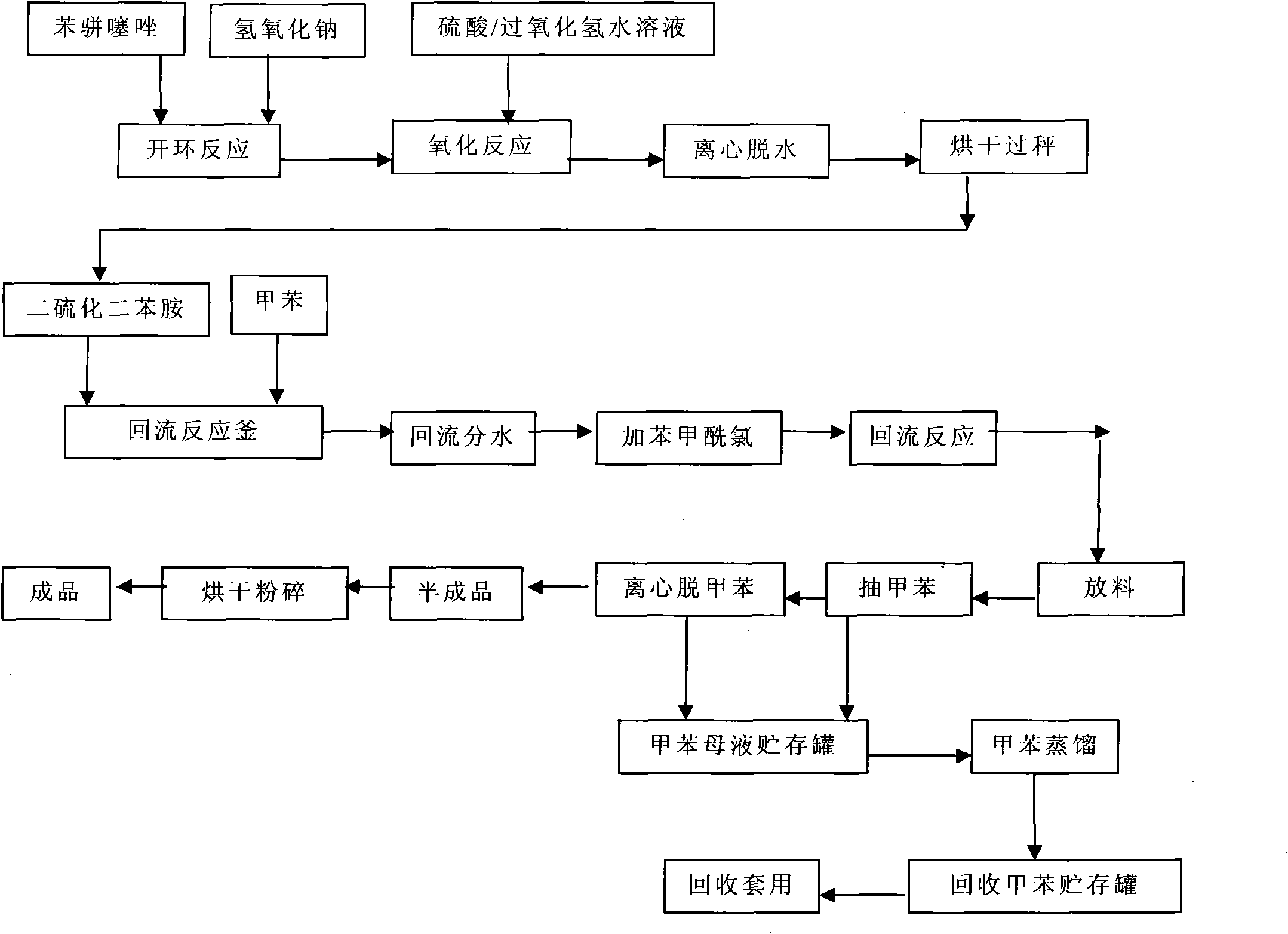

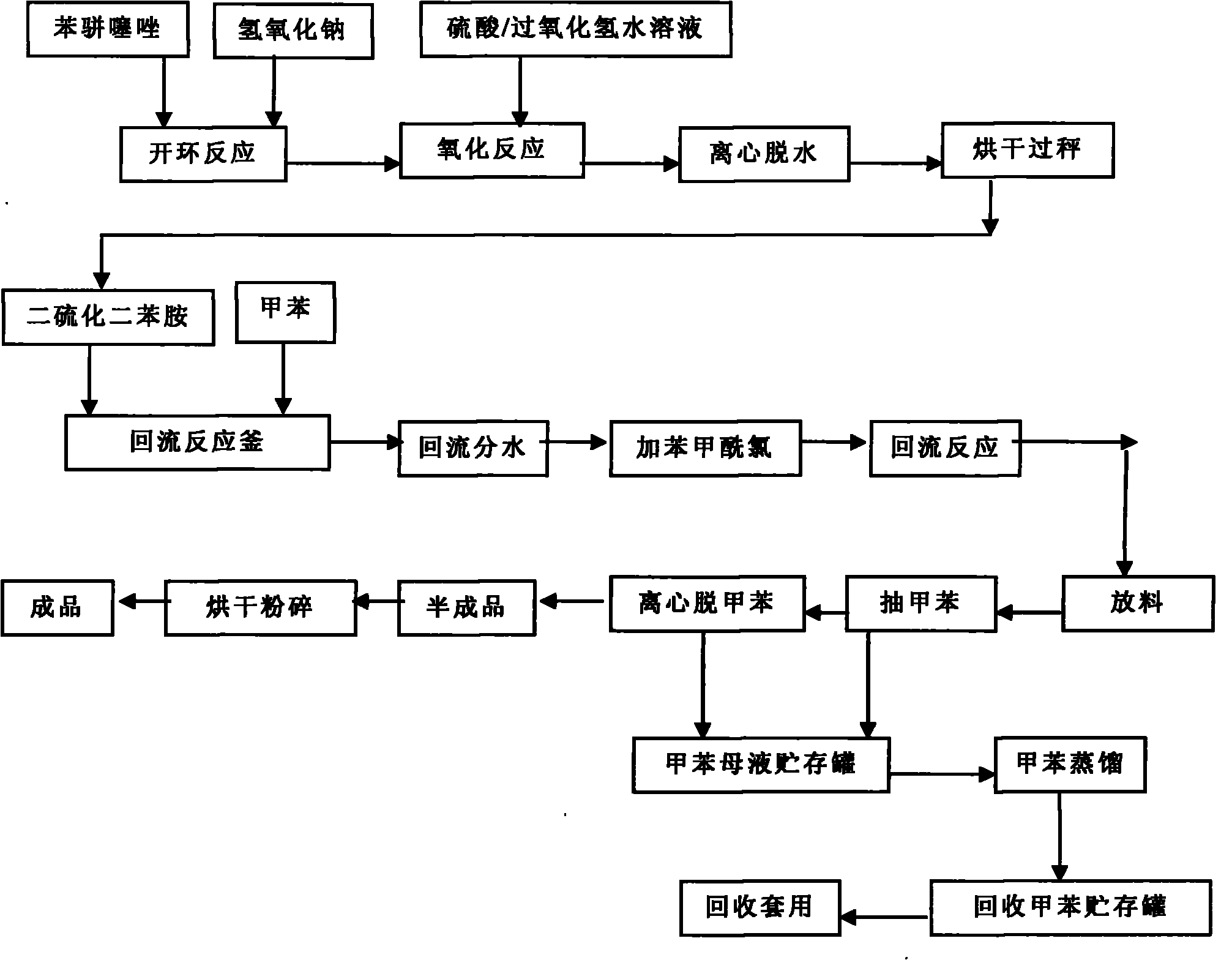

Method for preparing rubber peptizer DBD

ActiveCN102153495ALow costReduce the cost of three wastes treatmentHydropoly/poly sulfide preparationPolymer scienceBisulfide

The invention relates to a method for preparing a rubber auxiliary agent, and particularly discloses a method for preparing rubber peptizer 2,2-dibenzoylamino diphenyl disulphide (DBD). The method for preparing the rubber peptizer DBD is characterized by comprising the following steps of: performing ring opening reaction on benzothiazole to obtain a ring opening product; oxidizing the ring opening product to prepare diphenylamine disulphide; and performing acylation reaction on the diphenylamine disulphide and benzoyl chloride to generate the DBD. According to the method for preparing the rubber peptizer DBD, compared with the conventional process, the product cost is remarkably reduced; the method is favorable for popularization and application of the environmentally-friendly peptizer DBD, and simultaneously breaks through the situation that the product depends on import for a long term; the organic solvent is used as a reaction medium and can be recycled, so little three-waste is discharged; and the production flow is simple and easily controlled, high-temperature and high-pressure reaction does not exist in the method, the equipment investment is low, and the method is easy for production and operation.

Owner:HEZE JIACHENG CHEM CO LTD

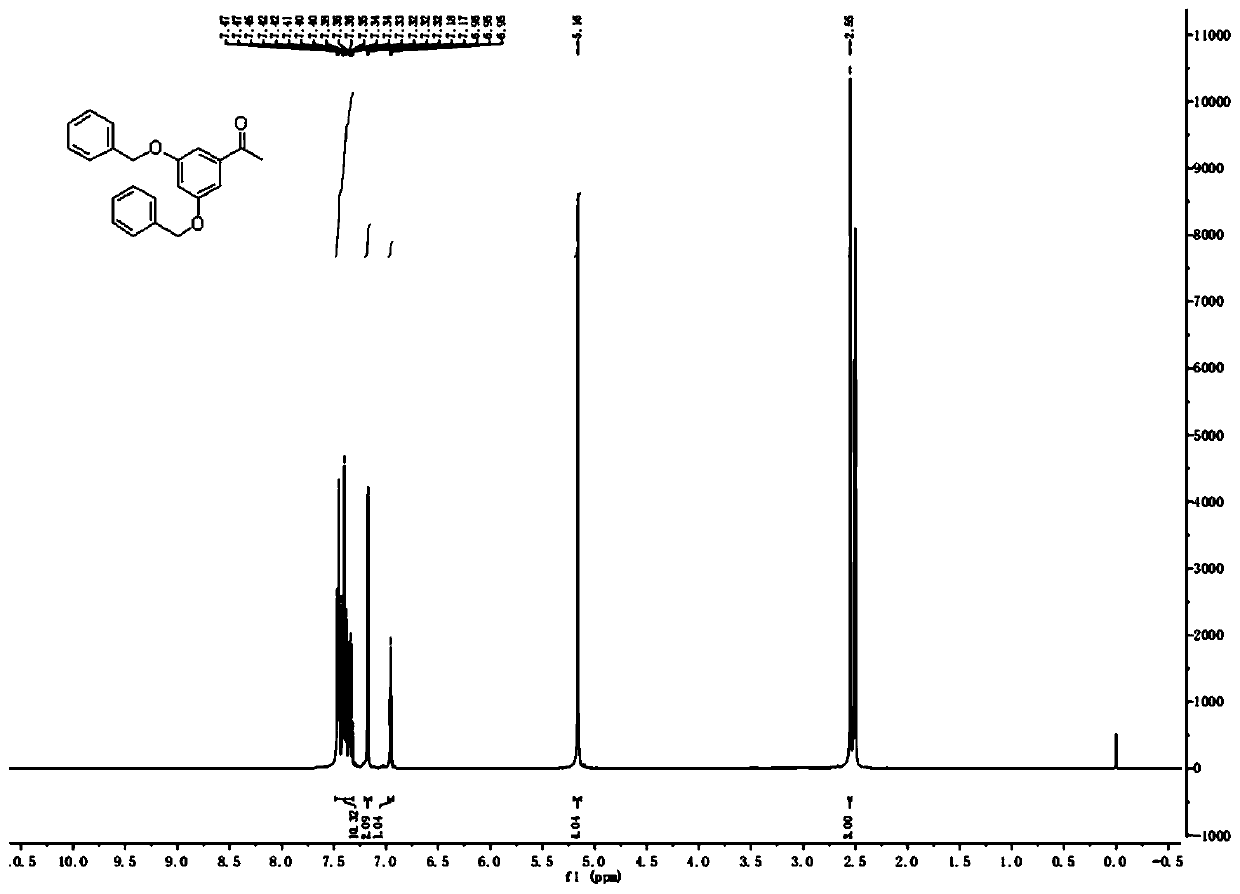

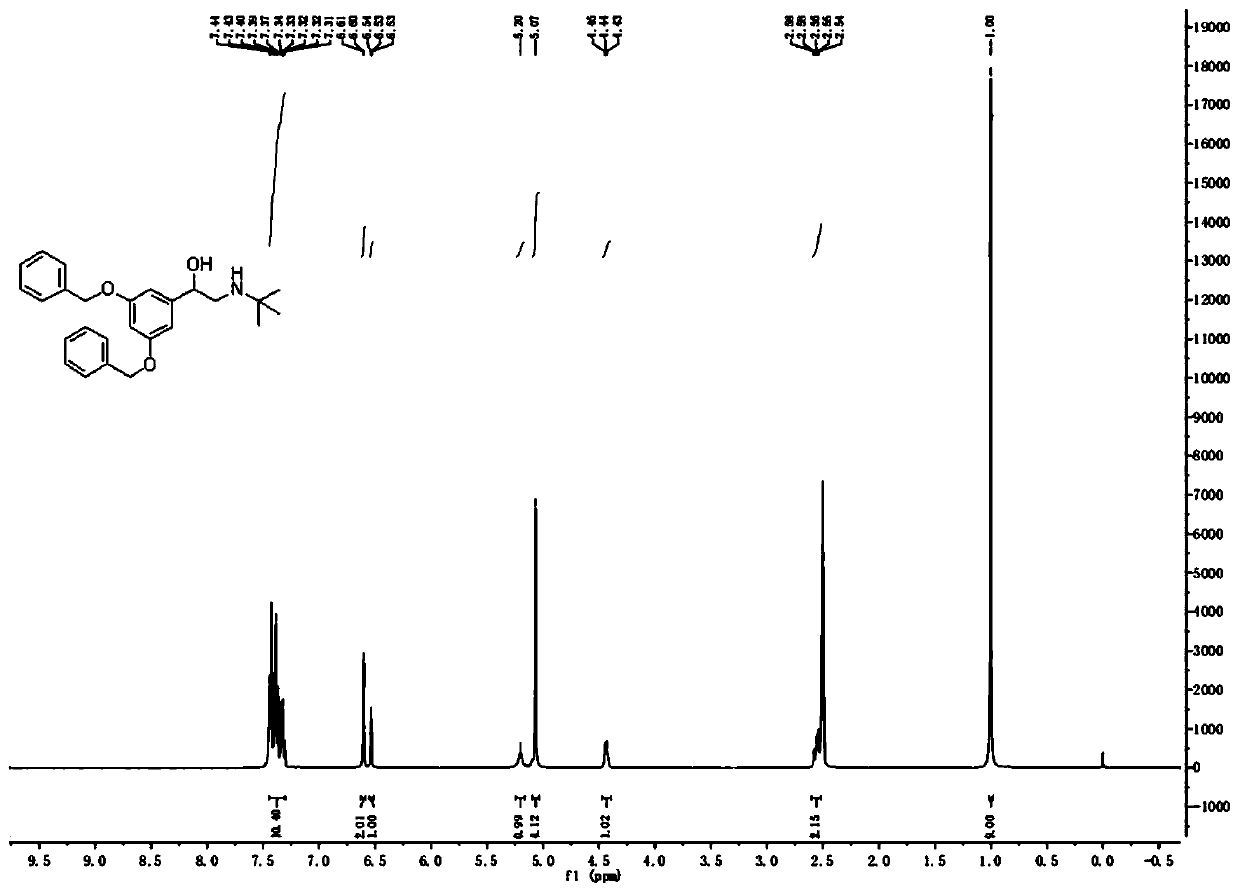

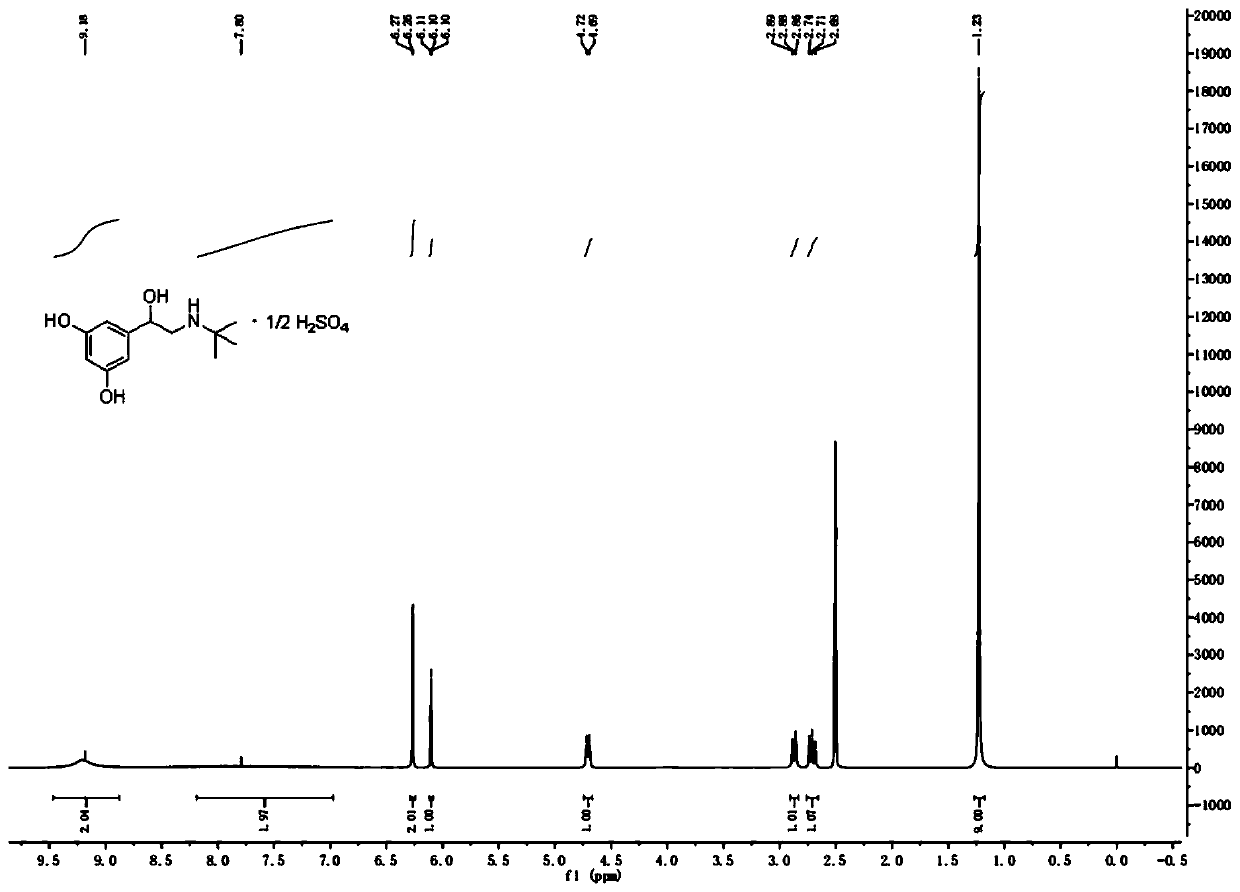

Preparation method of terbutaline sulfate

ActiveCN110950765AReduce usageAvoid high temperature and high pressure reactionsOrganic compound preparationCarbonyl compound preparationAcetophenonePhenyl group

The invention discloses a preparation method of terbutaline sulfate. The method comprises the steps: taking 3,5-dihydroxyacetophenone as an initial raw material, firstly, carrying out benzyl protection to obtain 3,4-dibenzyloxyacetophenone, carrying out copper bromide bromination and DMSO oxidation on 3,5-dibenzyloxyacetophenone to obtain 3,5-dibenzyloxyacetophenone aldehyde, carrying out reductive amination on 3,5-dibenzyloxyacetophenone aldehyde and tert-butylamine to generate 1-[3,5-di(benzyloxy)phenyl]-2-(tert-butylamino)ethanol, and finally carrying out hydrogenation debenzylation and sulfuric acid salification, to obtain terbutaline sulfate. Compared with the prior art, the method has the advantages that the used raw materials and auxiliary materials are cheap and easily available, the use of high-risk and highly-toxic reagents is avoided, high-temperature and high-pressure reaction is avoided, the operation is simple and convenient, the reaction conditions are mild, and the defects of long steps, low yield, potential safety hazards and the like in the prior art are overcome.

Owner:ZHEJIANG PHARMA COLLEGE

Production method of glycine

InactiveCN103539687AImprove product qualityQuality improvementOrganic compound preparationAmino-carboxyl compound preparationHyperprolinemiaHigh pressure

The invention discloses a production method of glycine. The glycine belongs to the field of preparation of amino acid. The glycine finished product is prepared through processes such as synthesizing, decoloring, crystallizing, centrifugal separation and drying based on monochloro acetic acid, ammonium hydroxide, activated carbon and 95% ethanol as raw materials, and a reaction kettle, a decoloring kettle, a crystallization kettle, a centrifugal machine and a vacuum drier as equipment. The production method has the advantages that the process is simple, the general equipment is adopted, no three wastes (waste gas, waste gas and solid waste) are discharged, high-temperature high-pressure reaction is not performed, the operation is convenient, the glycine is high in quality, and high-quality glycine can be produced as mass. The glycine can be applied to pharmaceutical treatment of diseases such as myasthenia gravis, progressive muscular dystrophy, gastric ester excess symptom, chronic enteritis and children hyperprolinemia, and can serve as a nutritive additive of chicken feed, serve as a seasoning and a preservative for foods and serve as an intermediate in agrochemical production.

Owner:XINYI HANLING BIO ENG

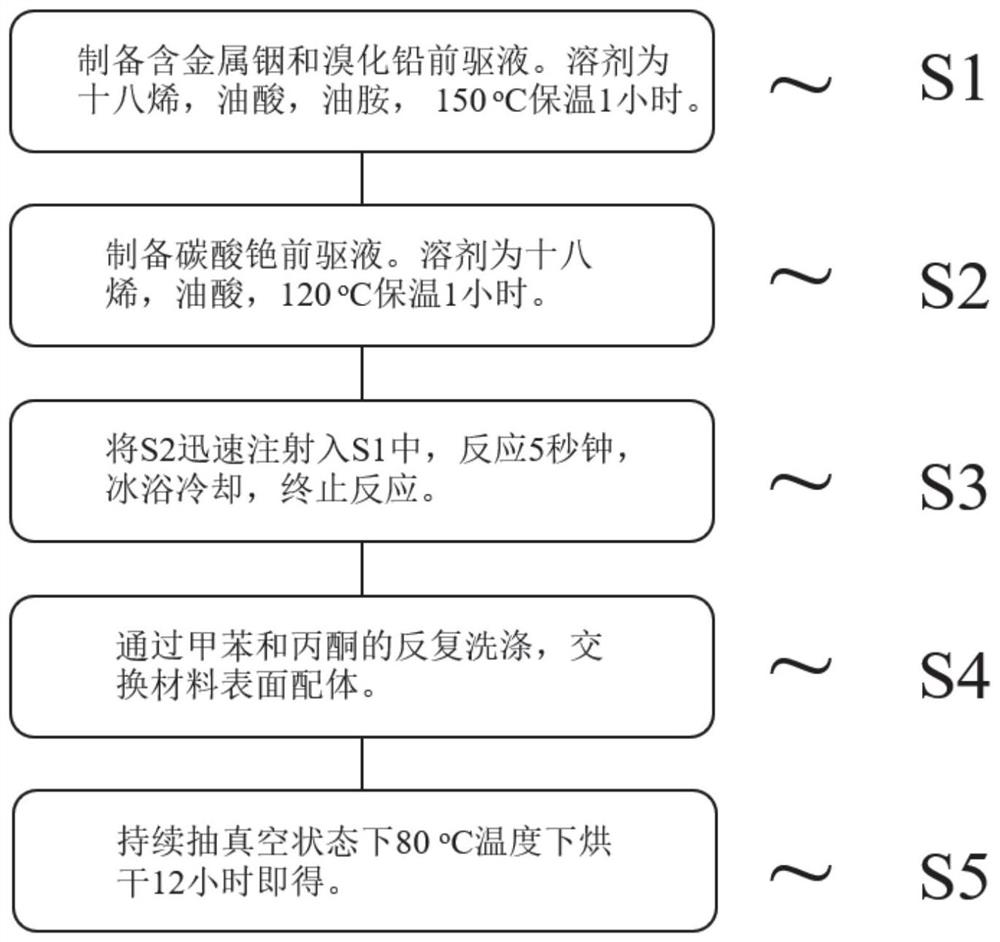

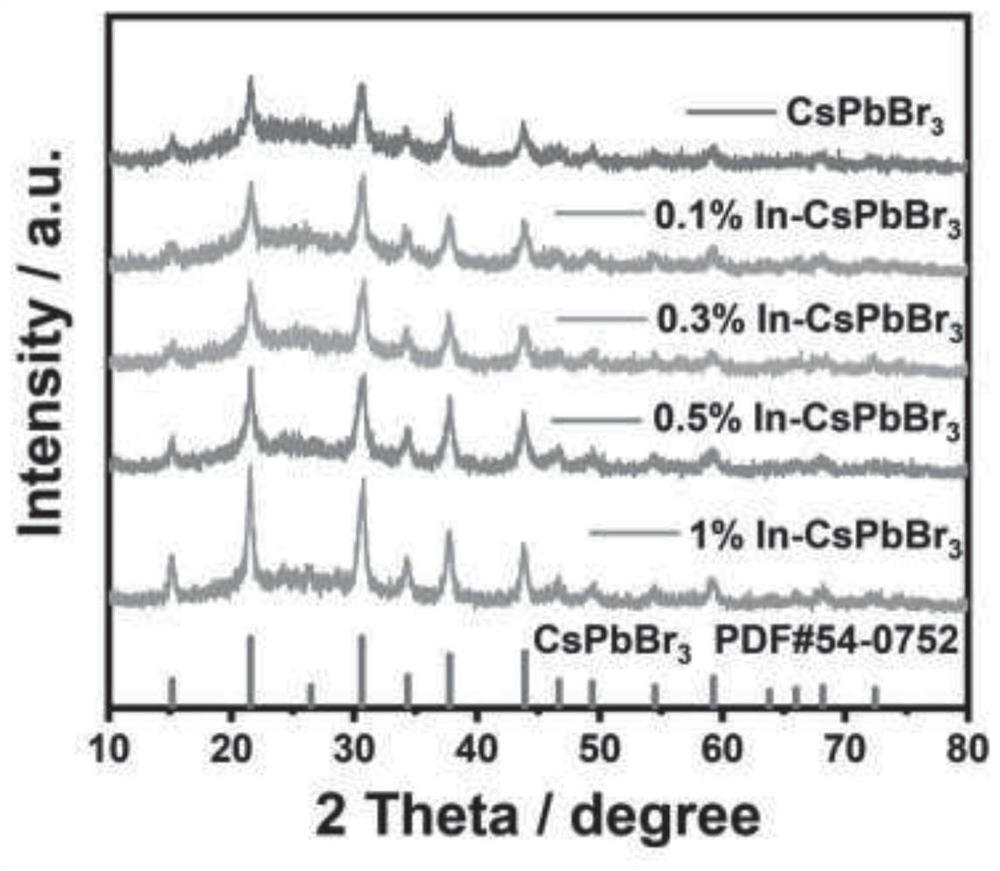

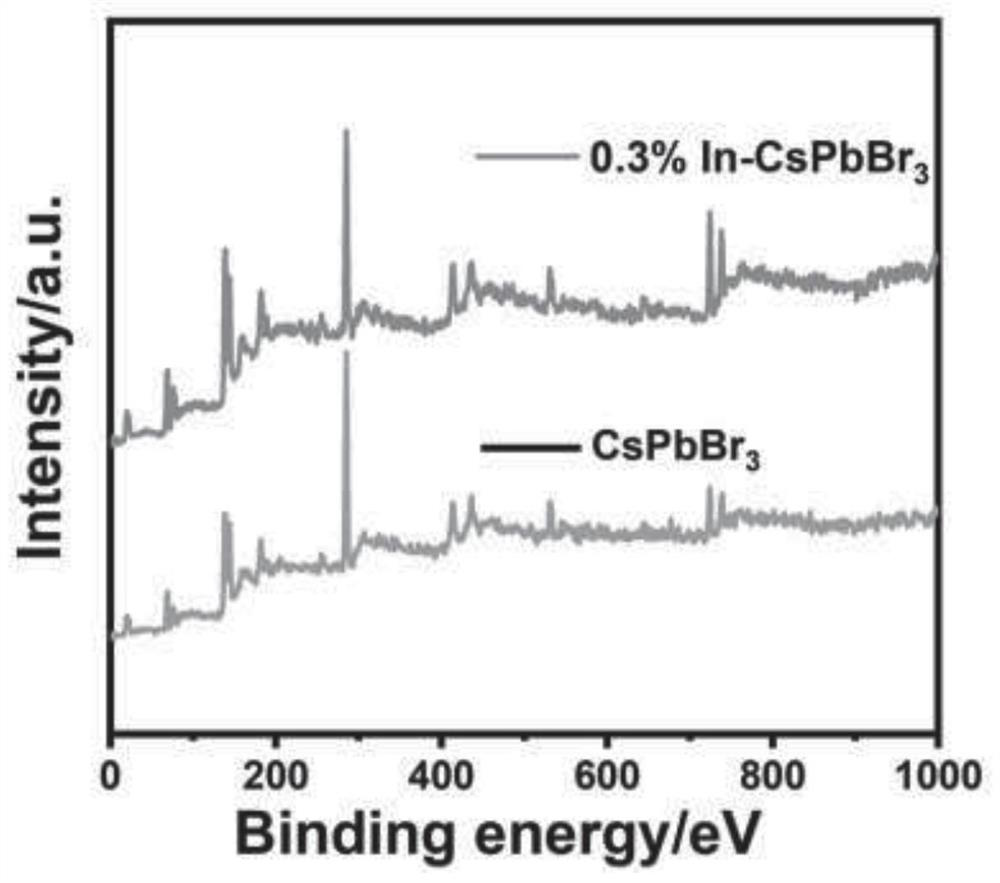

Metal indium-doped cesium lead bromide perovskite quantum dot photocatalyst and preparation method thereof, and application of metal indium-doped cesium lead bromide perovskite quantum dot photocatalyst in reduction of carbon dioxide

ActiveCN113198496AImprove stabilityInhibition of adsorptionMaterial nanotechnologyPhysical/chemical process catalystsPtru catalystHalogen

The invention discloses a metal indium-doped CsPbBr3 perovskite quantum dot photocatalyst. The photocatalyst is characterized in that halogen perovskite quantum dots are used as a carrier, and metal indium is doped in the halogen perovskite quantum dots to serve as an active center. A preparation method of the photocatalyst comprises the following steps: S1, preparing a precursor solution containing metal indium and lead bromide; S2, preparing a cesium carbonate precursor solution; S3, rapidly injecting the cesium carbonate precursor solution into the precursor solution containing the metal indium and the lead bromide for a reaction, conducting cooling in an ice bath, and then terminating the reaction; S4, exchanging a ligand on the surface of a catalyst through repeated washing of methylbenzene and acetone; and S5, conducting drying in a continuous vacuumizing state to obtain the photocatalyst. The photocatalytic carbon dioxide reduction performance of the metal indium-doped CsPbBr3 perovskite quantum dot photocatalyst disclosed by the invention is 1.48 to 3.25 times the photocatalytic carbon dioxide reduction performance of a pure-phase CsPbBr3 perovskite quantum dot photocatalyst, and the stability of the CsPbBr3 perovskite quantum dot photocatalyst is greatly improved.

Owner:YANGTZE DELTA REGION INST OF UNIV OF ELECTRONICS SCI & TECH OF CHINE HUZHOU

Production method for methyl aspartate

InactiveCN106748841ASimple production processHigh yield of finished productsOrganic compound preparationAmino-carboxyl compound preparationChemistrySulfuric acid

The invention discloses a production method for methyl aspartate, belonging to the field of production of amino acids. According to the production method, methyl aspartate is prepared from aspartic acid powder, sulfuric acid with a concentration of 30%, solid acid and a methanol solution through production of sulfate of aspartic acid at first and esterification next. The production method has the advantages of usage of universal equipment, simple production process, no high-temperature and high-pressure reaction, environmental protection, high product output and capacity of producing a high-purity finished methyl aspartate product; and the finished methyl aspartate product is an intermediate for production of asparagine.

Owner:XINYI HANLING BIO ENG

Method for synthesizing glutaric acid from alpha-ketoglutaric acid

ActiveCN108047032AWide variety of sourcesReduce manufacturing costOrganic compound preparationCarboxylic acid amides preparationGlutaric acidKetone

The invention relates to a method for synthesizing glutaric acid from alpha-ketoglutaric acid. Specifically, under the mild condition, protected ketone thioacetal is subjected to catalytic hydrogenation reduction with raney nickel, recycling and reusing of reactants, solvent and a catalyst are achieved in a carbonyl reduction part in the most critical step, and the method for preparing the largely-demanded glutaric acid with the simple four-step method is developed. According to the method, the glutaric acid with the high yield is synthesized with the method for the first time, the yields of all steps are 92%, 78.6%, 90% and 85% in sequence, and the total yield is 55.32%; the method has broad prospects in synthetic application of compound library establishment.

Owner:TIANJIN UNIV OF SCI & TECH

Method for preparing titanium-rich material from titanium-containing blast furnace slags by virtue of fusion treatment of boric acid

InactiveCN103882241ASimple processNo high temperature and high pressure reactionProcess efficiency improvementSlagTitanium

The invention belongs to the field of metallurgy, and particularly relates to a method for preparing a titanium-rich material from titanium-containing blast furnace slags by virtue of fusion treatment of boric acid. A technical problem to be solved by the invention is to provide a simple, environment-friendly and low-power consumption method for preparing the titanium-rich material from the titanium-containing blast furnace slags as well as the titanium-rich material prepared by the method. For solving the technical problem, a technical scheme adopted by the method comprises the following steps: batching ball-milled blast furnace slags with boric acid, heating to perform a fusion reaction, cooling, crushing, leaching by use of hydrochloric acid, filtering and separating. The titanium-rich material prepared by the preparation method disclosed by the invention contains not less than 60% by mass of TiO2. The preparation method disclosed by the invention has the advantages that the technological process is simple, and high-temperature and high-pressure reactions are not needed; the power consumption is low; the acid used in leaching is low in concentration and low in usage amount, so the process is more environmental friendly; a mixture formed after the crushing is washed with hot water, the hot water after washing is concentrated and crystallized, and boric acid is recycled, so the cost is low.

Owner:PANZHIHUA UNIV

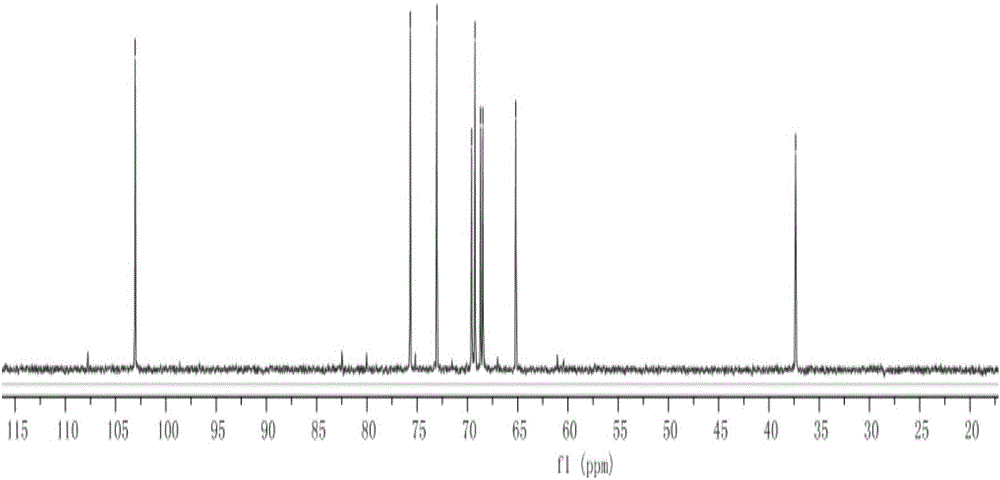

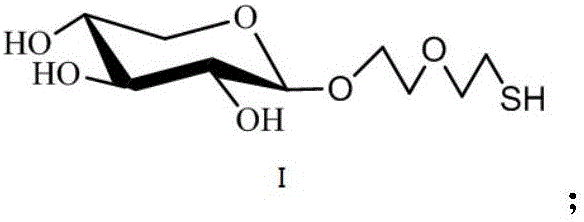

Xylose compound with terminal group containing HS-(PEG)-2-O branch chain and synthesis method of xylose compound

InactiveCN106543242AImprove responseMild conditionsEsterified saccharide compoundsSugar derivativesSodium methoxideGlycoside

The invention discloses a xylose compound with a terminal group containing a HS-(PEG)-2-O branch chain and a synthesis method of the xylose compound with the terminal group containing the HS-(PEG)-2-O branch chain. The compound is shown as the formula I (the formula is shown in the description). The synthesis method comprises the following steps that xylose is subjected to an acetylation or benzoylation reaction and terminal group glycosylation sequentially and then reacts with potassium thioacetate in a N,N-dimethylformamide solution at normal temperature, Ac or Bz protecting group removal is finally conducted with sodium methylate / methanol, and then the xylose compound with the terminal group containing the HS-(PEG)-2-O branch chain is obtained. The xylose compound with the terminal group containing the HS-(PEG)-2-O branch chain shows the good water solubility due to the fact that multiple -OH are contained and can be applied to quantum dot surface modification due to the fact that -SH is contained; the application field of the xylose compound is widened due to the fact that the xylose compound has multiple chiral centers, and therefore specific identifiability of glucose and combination of quantum dot special material properties are achieved.

Owner:GUANGXI TEACHERS EDUCATION UNIV

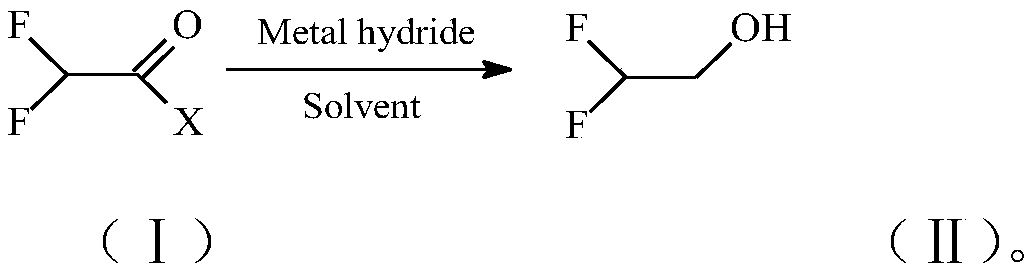

Preparation method of 2,2-difluoroethanol

PendingCN111499492AHigh yieldThe process steps are simpleOrganic compound preparationHydroxy compound preparationFluid phaseCombinatorial chemistry

The invention discloses a preparation method of 2,2-difluoroethanol. 2,2-difluoroethanol is obtained by liquid-phase one-step reaction of 2,2-difluoroacetyl halide and a metal hydride. The method provided by the invention has the advantages of high product yield, simple reaction steps, mild reaction conditions and the like.

Owner:SINOCHEM MODERN ENVIRONMENTAL CHEM INDAL XI ANCO +1

Reverse demulsifier and its preparation method

ActiveCN102559246BGood demulsification effectLow equipment requirementsDewatering/demulsification with chemical meansEthylenediamineHigh pressure

The invention discloses a reverse demulsifier and its preparation method. The method comprises allowing reaction between methyl acrylate and ethylenediamine to obtain linear polyamidoamine, and allowing reaction between the linear polyamidoamine and epoxy chloropropane to obtain quaternary ammonium salt of linear polyamidoamine; allowing free-radical polymerization between polyoxyethylene nonylphenyl ether acrylate, acryloyloxyethyltrimethylammonium chloride and acrylamide in the present of an initiator and a terminator to obtain amphipathic cationic polymer; and mixing the quaternary ammonium salt of linear polyamidoamine, the amphipathic cationic polymer, a cationic surfactant and water to obtain the reverse demulsifier. The inventive reverse demulsifier has good demulsification effect on oil-in-water emulsion produced from oil field, and is suitable for chemical flooding produced fluid; and the inventive preparation method has low requirement for equipment, and is free of high-temperature high-pressure reaction.

Owner:CHINA NAT OFFSHORE OIL CORP +1

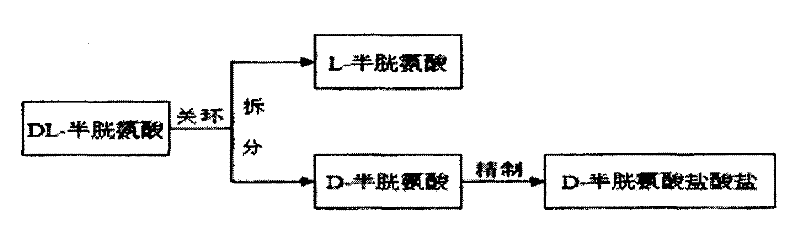

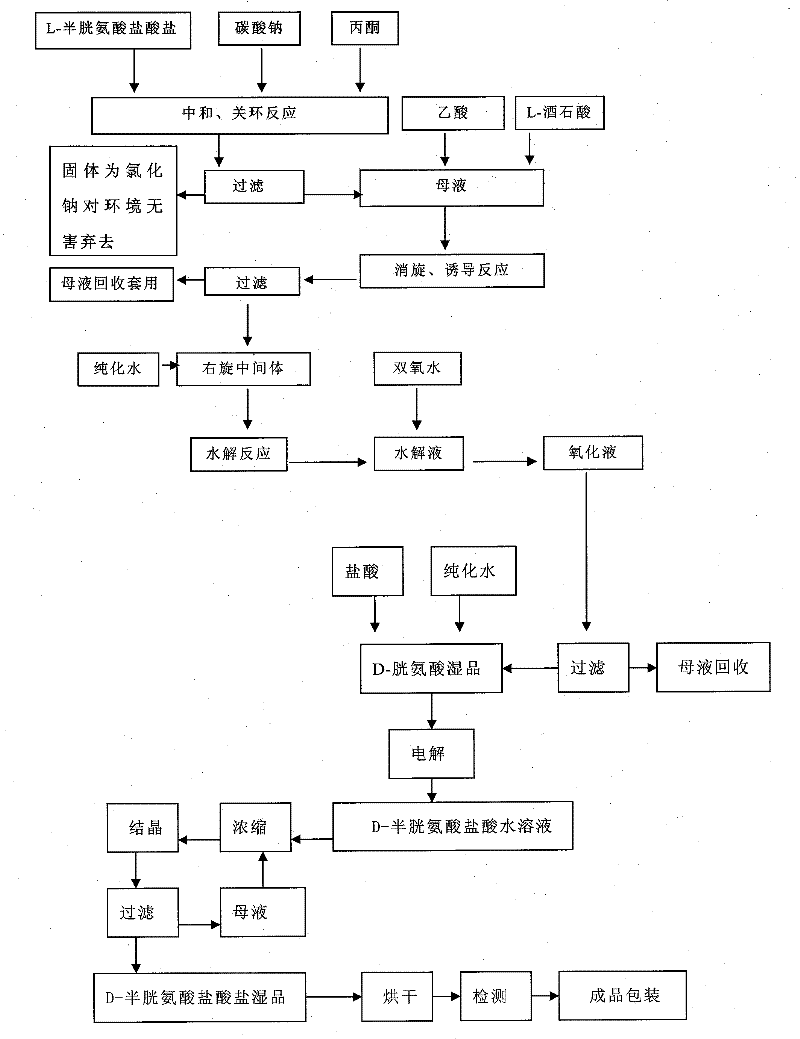

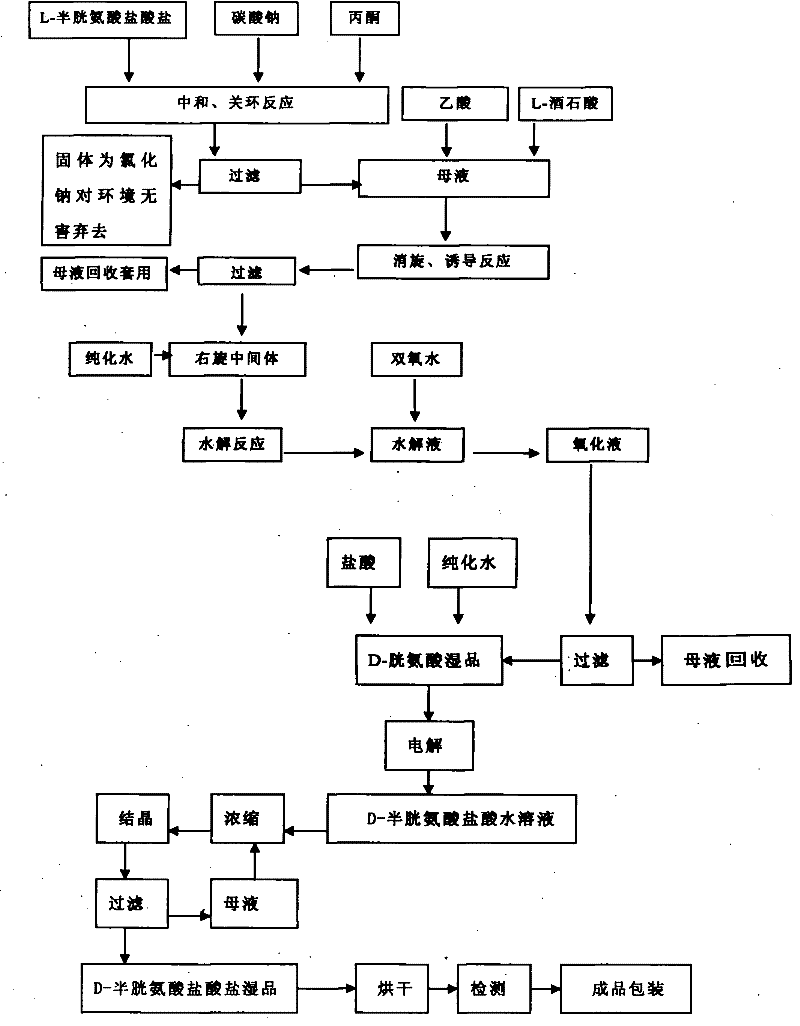

Method for preparing D-cysteine hydrochloride-hydrate

The invention relates to a method for preparing a medicine intermediate, and particularly discloses a method for preparing D-cysteine hydrochloride-hydrate. The method for preparing the D-cysteine hydrochloride-hydrate is characterized by comprising the following steps of: carrying out neutralization cyclization on L-cysteine hydrochloride to obtain a ring-closing product; carrying out racemization on the ring-closing product, adding revulsive, transforming and separating out a dextral intermediate; carrying out hydrolysis ring-opening on the dextral intermediate, oxidizing to obtain D-cystine; and carrying out electrolysis concentration and crystallization on the D-cystine to obtain the D-cysteine hydrochloride-hydrate. By transforming the L-cysteine hydrochloride into the D-cysteine hydrochloride-hydrate, the method for preparing the D-cysteine hydrochloride-hydrate greatly lowers the production cost, the D-cysteine hydrochloride-hydrate has high yield and good quality, less emission of three wastes as an organic solvent is used as a reaction medium; and the production flow is simple, no high-temperature and high-pressure reaction exists, the equipment investment is less, and the production operation is easy.

Owner:曹县思达化工有限公司

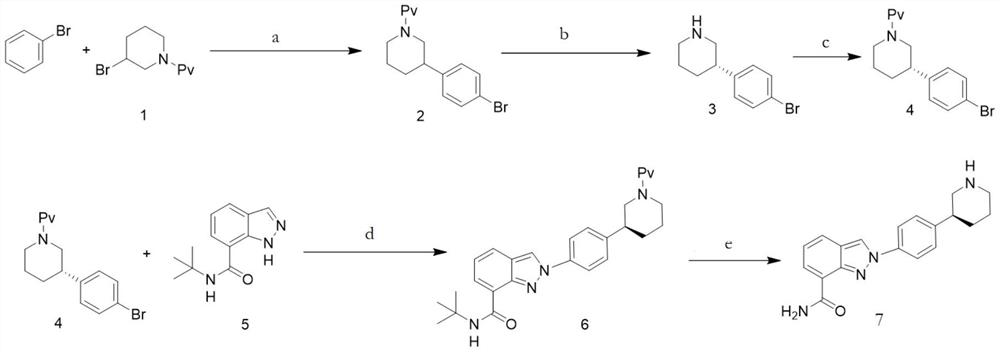

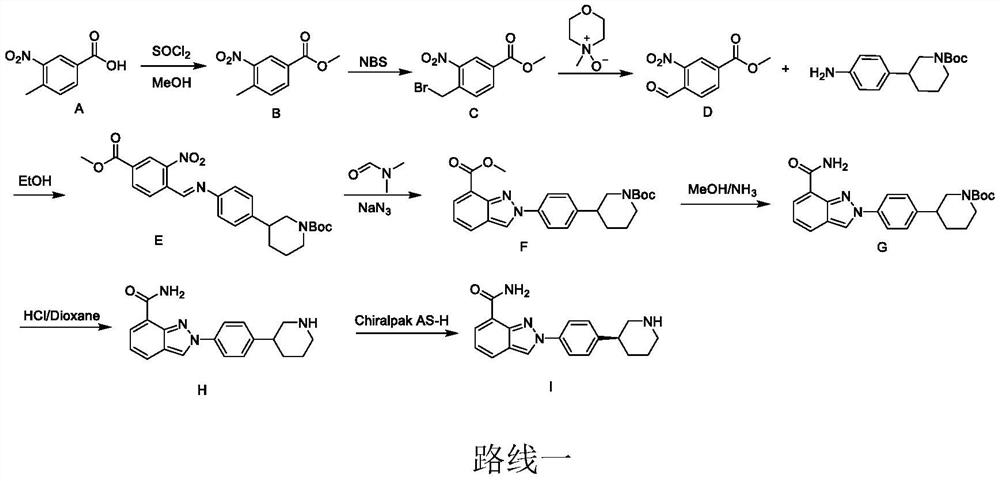

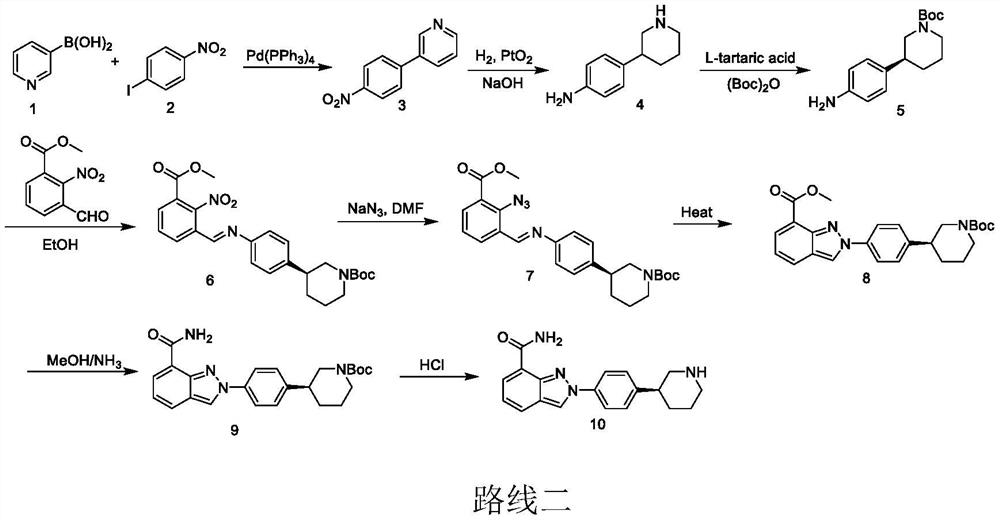

Niraparib preparation method

ActiveCN113637002AAdvantages of preparation methodThe synthesis process is simpleOrganic chemistry methodsPtru catalystCombinatorial chemistry

The invention provides a niraparib preparation method, which comprises: carrying out photocatalysis on a compound 1 and bromobenzene under a Pd catalyst to obtain a niraparib key intermediate; carrying out chiral resolution on the niraparib key intermediate, and coupling the niraparib key intermediate with NBoc-1H-indazole-7-carboxamide under the catalysis of copper bromide to obtain protected niraparib; and removing the protective color of the protected niraparib under the action of methanesulfonic acid, and obtaining the target product niraparib under tetrahydrofuran pulping. The preparation method of niraparib is simple in synthesis process route, high in preparation efficiency, small in damage to human bodies and the environment and low in synthesis cost.

Owner:天津太平洋化学制药有限公司

Preparation method of high-purity D-cystine

PendingCN112321470AHigh purityHigh yieldOrganic compound preparationOrganic chemistry methodsThiazoleHydrolysate

The invention discloses a preparation method of high-purity D-cystine. The preparation method comprises the following steps: hydrolyzing D-2, 2-dimethyltetrahydrothiazole-4-carboxylic acid.L-tartrate,and converting the hydrolysate, specifically, converting L-tartaric acid in the hydrolysate into Lentinite, which is separated out as a precipitate; then, before the filtrate is oxidized, the pH value of the filtrate is firstly reduced so that introduction of more impurities in the oxidation process is reduced, and high-purity and high-yield D-cysteine is obtained; the whole preparation method issimple in production process, safe in used raw materials, easy to control, free of high-temperature and high-pressure reaction, low in equipment investment and easy to produce and operate.

Owner:山东嘉成医药科技有限公司

Granulation method of amino acid solution

InactiveCN106747677ASimple production processNo high temperature and high pressure reactionNitrogenous fertilisersSolid/semi-solid fertilisersRoom temperatureHigh pressure

The invention discloses a granulation method of an amino acid solution and belongs to the field of amino acid production. The granulation method utilizes an amino acid solution as a raw material and comprises concentration, granulation and packaging. The granulation method utilizes general equipment, has simple processes, is free of a high temperature and high pressure reaction, and realizes room temperature granulation and mass production of amino acid particles. The product is mainly used for preparation of a variety of organic and inorganic composite fertilizers.

Owner:XINYI HANLING BIO ENG

Method for preparing n-tetradecane under normal pressure

InactiveCN101987804ASimple production processNo high temperature and high pressure reactionHydrocarbon from halogen organic compoundsAcetic acidHydrogen atom

The invention relates to a method for preparing n-tetradecane under normal pressure, which comprises the following steps of: (1) mixing glacial acetic acid, zinc powder and alkyl halides of the same grade; (2) dripping hydrochloric acid into the mixture, refluxing, precipitating and separating to obtain a liquid crude product of the n-tetradecane; (3) washing by using acid and alkali to obtain purified liquid of the n-tetradecane; and (4) distilling under reduced pressure to obtain a finished product of the n-tetradecane. The production process is simple, the zinc powder, bromoalkane and the hydrochloric acid are added at the temperature of below 110 DEG C under normal pressure, high-temperature and high-pressure reactions are not performed, and the process has low requirement on production equipment and low danger. In the method, a one-step synthetic mode of reducing the alkyl halides by using hydrogen atoms is adopted, and diethyl ether is replaced by sulfuric acid to remove unsaturated hydrocarbons and alcohols, the safety factor is high, and the condition is easy to control.

Owner:TIANJIN CHEM REAGENT RES INST

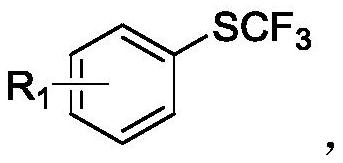

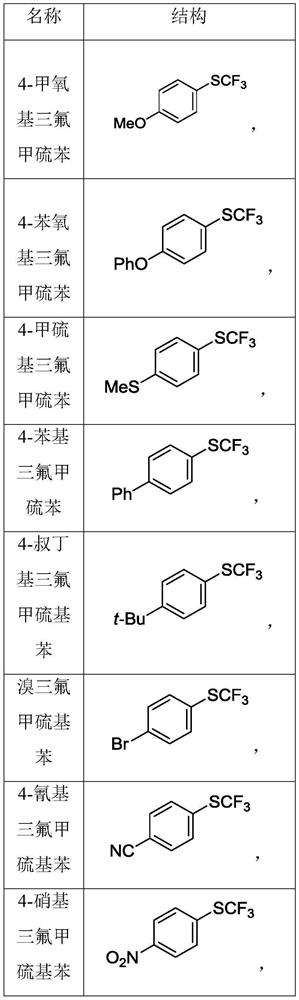

A process for converting substituted phenyl diazonium salts into [(trifluoromethyl)thio]benzene

The invention discloses a synthetic method of [(trifluoromethyl)thio]benzene compounds, particularly a method for converting substituted phenyl diazonium salts into [(trifluoromethyl)thio]benzene. Themethod comprises the following steps: under white light irradiation, adding an aryl diazonium salt, tris(2,2'-bipyridine)ruthenium(II) hexafluorophosphate and S-trifluoromethyl-4-methoxybenzenesulfonyl sulfate into a solvent and uniformly mixing the mixture; after mixing, reacting the mixture at the room temperature of 20-25 DEG C; determining the reaction ending time through spotting detection;after the reaction is finished, adding water for extraction; performing separation to obtain a liquid organic phase; drying the liquid organic phase with anhydrous Na2SO4; then removing a solvent; andperforming rapid separation with column chromatography to obtain a [(trifluoromethyl)thio]benzene compound. The method is mild in reaction condition, free of high-temperature and high-pressure reaction, safe in reaction condition and suitable for large-scale production and development.

Owner:TIANJIN NORMAL UNIVERSITY

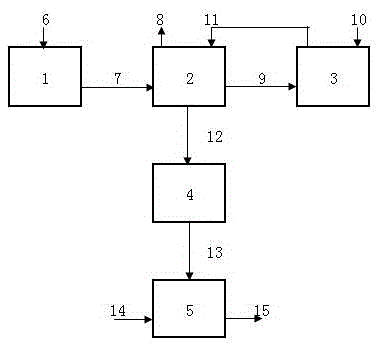

Mechanical device for production of methyl aspartate

InactiveCN106748842AHigh yieldHigh purityOrganic compound preparationAmino-carboxyl compound preparationBiochemical engineeringAspartic acid

Belonging to the field of amino acid production machinery, the invention discloses a mechanical device for production of methyl aspartate. The device comprises: a first stirring tank (1), a filter (2), a second stirring tank (3), a dryer (4), and a packaging machine (5). The mechanical device is characterized in that: the first stirring tank (1) is provided with a first raw material inlet (6), a first slurry pump and a pipeline (7), the filter (2) is equipped with a filtrate outlet (8), a first conveyor (9) is disposed between the filter (2) and the second stirring tank (3), the second stirring tank (3) is equipped with a second raw material inlet (10), a second slurry pump and a pipeline (11) are disposed between the second stirring tank (3) and the filter (2), a second conveyor (12) is disposed between the filter (2) and the dryer (4), a third conveyor (13) is disposed between the dryer (4) and the packaging machine (5), and the packaging machine (5) is provided with a packaging bag inlet (14) and a product outlet (15).

Owner:XINYI HANLING BIO ENG

Amino acid solution granulating method

InactiveCN109225062ASimple production processNo high temperature and high pressure reactionGranulation by liquid drop formationNitrogenous fertilisersFertilizerChemistry

The invention discloses an amino acid solution granulating method. The method belongs to the field of amino acid production. The raw materials used by the production method comprise an amino acid solution, and a finished product is prepared by the work procedures of concentrating, granulating, packaging and the like. The amino acid solution granulating method disclosed by the invention has the advantages: general equipment is utilized, a production technology is simple, high temperature and high pressure reaction is avoided, granulation at normal temperature is achieved, amino acid particles can be batch produced, and the product is mainly applied to preparing varieties of organic-inorganic compound fertilizer.

Owner:丁杰

Method for preparing titanium-rich material by melting treatment of titanium-containing blast furnace slag with boric acid

InactiveCN103882241BSimple processNo high temperature and high pressure reactionProcess efficiency improvementSlagTitanium

The invention belongs to the field of metallurgy, and particularly relates to a method for preparing a titanium-rich material from titanium-containing blast furnace slags by virtue of fusion treatment of boric acid. A technical problem to be solved by the invention is to provide a simple, environment-friendly and low-power consumption method for preparing the titanium-rich material from the titanium-containing blast furnace slags as well as the titanium-rich material prepared by the method. For solving the technical problem, a technical scheme adopted by the method comprises the following steps: batching ball-milled blast furnace slags with boric acid, heating to perform a fusion reaction, cooling, crushing, leaching by use of hydrochloric acid, filtering and separating. The titanium-rich material prepared by the preparation method disclosed by the invention contains not less than 60% by mass of TiO2. The preparation method disclosed by the invention has the advantages that the technological process is simple, and high-temperature and high-pressure reactions are not needed; the power consumption is low; the acid used in leaching is low in concentration and low in usage amount, so the process is more environmental friendly; a mixture formed after the crushing is washed with hot water, the hot water after washing is concentrated and crystallized, and boric acid is recycled, so the cost is low.

Owner:PANZHIHUA UNIV

Method for preparing rubber peptizer DBD

ActiveCN102153495BLow costBreak the long-term dependence on importsHydropoly/poly sulfide preparationThiazoleOrganosolv

The invention relates to a method for preparing a rubber auxiliary agent, and particularly discloses a method for preparing rubber peptizer 2,2-dibenzoylamino diphenyl disulphide (DBD). The method for preparing the rubber peptizer DBD is characterized by comprising the following steps of: performing ring opening reaction on benzothiazole to obtain a ring opening product; oxidizing the ring opening product to prepare diphenylamine disulphide; and performing acylation reaction on the diphenylamine disulphide and benzoyl chloride to generate the DBD. According to the method for preparing the rubber peptizer DBD, compared with the conventional process, the product cost is remarkably reduced; the method is favorable for popularization and application of the environmentally-friendly peptizer DBD, and simultaneously breaks through the situation that the product depends on import for a long term; the organic solvent is used as a reaction medium and can be recycled, so little three-waste is discharged; and the production flow is simple and easily controlled, high-temperature and high-pressure reaction does not exist in the method, the equipment investment is low, and the method is easy for production and operation.

Owner:HEZE JIACHENG CHEM CO LTD

Method for the synthesis of glutaric acid from alpha-ketoglutaric acid

ActiveCN108047032BWide variety of sourcesReduce manufacturing costOrganic compound preparationCarboxylic acid amides preparationGlutaric acidThioketal

Owner:TIANJIN UNIV OF SCI & TECH

A kind of preparation method of buvaracetam and its intermediate

The invention discloses a preparation method of a Buvaracetam intermediate shown in B-VI, comprising the following steps: dissolving B-IV and R-phenethylamine in a solvent, crystallizing, filtering, and recrystallizing to obtain B ‑V, which converts to B‑VI. In the preparation process of the present invention, no chiral chromatographic column is required to separate the isomers, and the effective components can be separated only by simple steps such as extraction, washing, drying, concentration, etc., the separation process is simple, and the production cost of brivaracetam is greatly reduced.

Owner:宜宾市南溪区红光制药有限公司

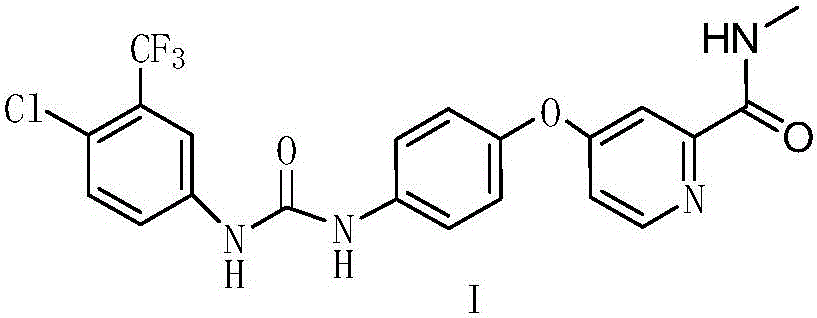

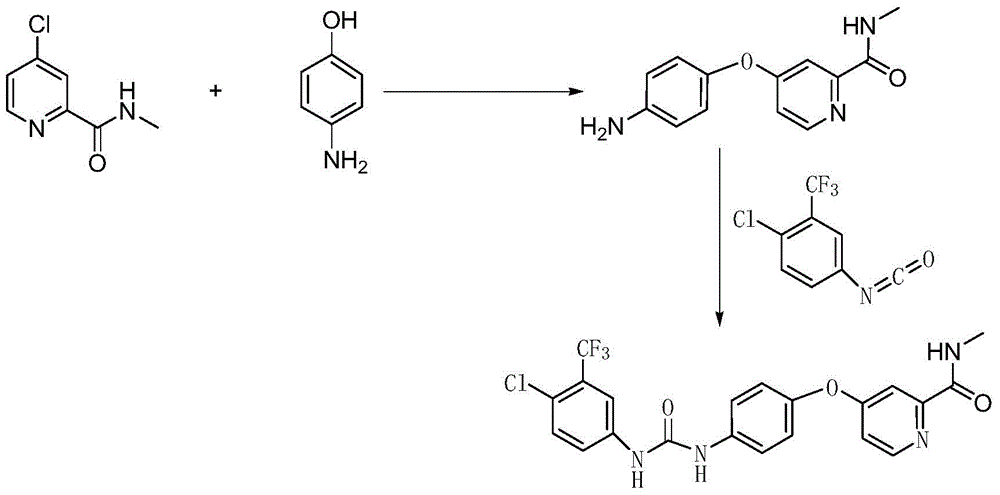

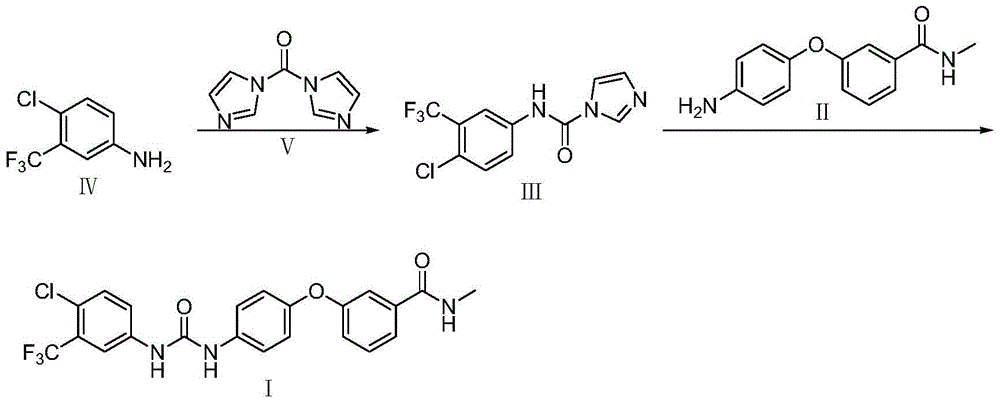

A kind of preparation method of Sorafenib

ActiveCN104402813BSimple processNo high temperature and high pressure reactionOrganic chemistryOrganic solventSolvent

The invention discloses a novel method for synthesizing sorafenib. The method comprises the following steps: using a (4-(4-aminophenoxy)-N-methylpyridine-2-carboxamide) compound II and a (4-chloro-3-trifluoromethylphenyl-carbamoyl-imidazole) compound III as raw materials, and reacting in an organic solvent inert to the compound III to produce a sorafenib crude product; then, dissolving the sorafenib crude product by the organic solvent and an organic or inorganic acid, and adding a solvent into which sorafenib is difficult to dissolve to enable the sorafenib to be separated out, so as to obtain a sorafenib pure product. The novel method is simple in technical process, ensures high product purity, facilitates operation and is suitable for large-scale industrial production.

Owner:哈药集团股份有限公司 +1

Method for converting substituted phenyl diazonium salts into trifluoromethylthiobenzene

The invention discloses a synthetic method of [(trifluoromethyl)thio]benzene compounds, particularly a method for converting substituted phenyl diazonium salts into [(trifluoromethyl)thio]benzene. Themethod comprises the following steps: under white light irradiation, adding an aryl diazonium salt, tris(2,2'-bipyridine)ruthenium(II) hexafluorophosphate and S-trifluoromethyl-4-methoxybenzenesulfonyl sulfate into a solvent and uniformly mixing the mixture; after mixing, reacting the mixture at the room temperature of 20-25 DEG C; determining the reaction ending time through spotting detection;after the reaction is finished, adding water for extraction; performing separation to obtain a liquid organic phase; drying the liquid organic phase with anhydrous Na2SO4; then removing a solvent; andperforming rapid separation with column chromatography to obtain a [(trifluoromethyl)thio]benzene compound. The method is mild in reaction condition, free of high-temperature and high-pressure reaction, safe in reaction condition and suitable for large-scale production and development.

Owner:TIANJIN NORMAL UNIVERSITY

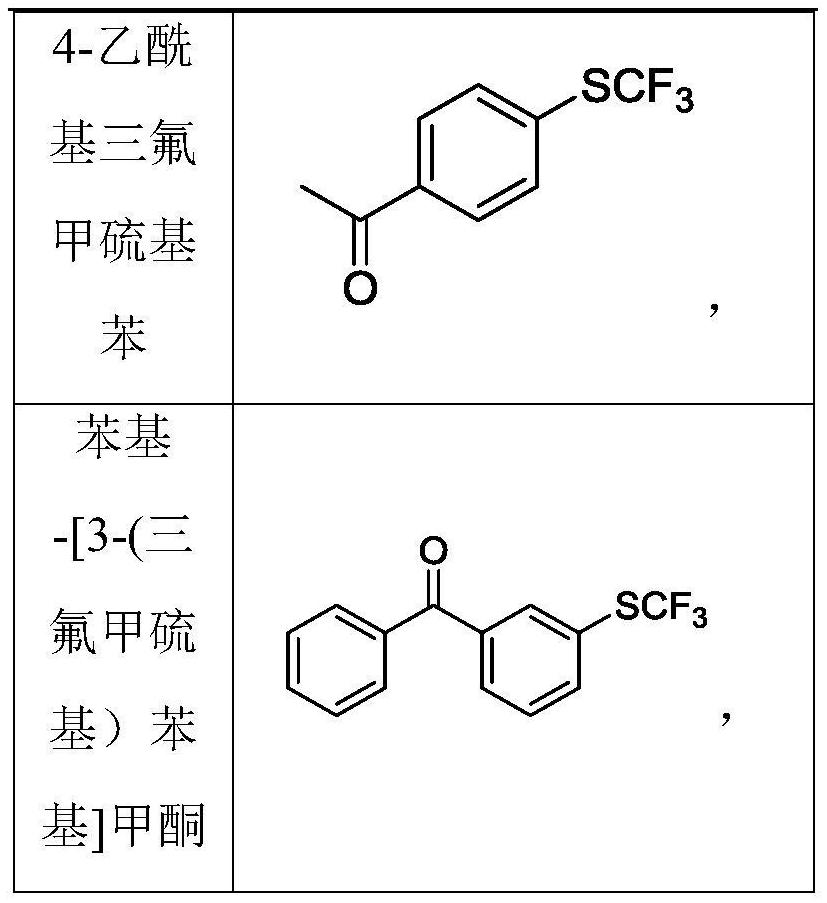

Preparation method of pharmaceutical armillarisin A

The invention relates to the technical field of pharmaceutical chemical preparation, in particular to a preparation method of pharmaceutical armillarisin A. The preparation method comprises the following specific steps: adding 3, 5-dihydroxybenzyl alcohol into ethanol, stirring and dissolving, adding ethoxymethylene ethyl acetoacetate, and stirring; dissolving metal sodium in ethanol to prepare sodium ethoxide; adding sodium ethoxide into the solution for reaction, standing and filtering to obtain a solid; dissolving the solid in purified water, adding activated carbon for decoloration, filtering to obtain filtrate, dropwise adding acid to adjust the pH value, and filtering to obtain an armillarisin A crude product; and putting the crude product into a mixed solution of absolute ethyl alcohol and purified water, adding ammonia water to dissolve the crude product, adding activated carbon to decolorize, filtering to obtain a filtrate, adding glacial acetic acid, cooling, crystallizing, filtering to obtain a refined armillarisin A product, and drying the refined product to obtain a finished armillarisin A product. Compared with the prior art, the method is simple in process operation, low in toxicity and high in yield, and the production cost can be further reduced. No catalyst is used, high-temperature and high-pressure reaction is avoided, reaction conditions are mild, and required equipment is simple.

Owner:SHANXI YUNPENG PHARMA

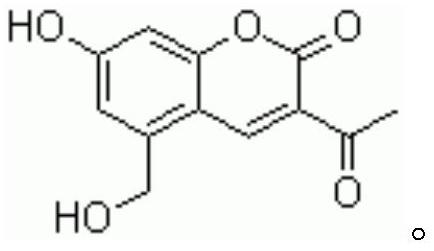

Eggeria, s-equol producing engineering bacteria and its construction method and application

ActiveCN105861363BThe fermentation process is simpleEasy to useBacteriaMicroorganism based processesMicroorganismEscherichia coli

Owner:HEBEI AGRICULTURAL UNIV.

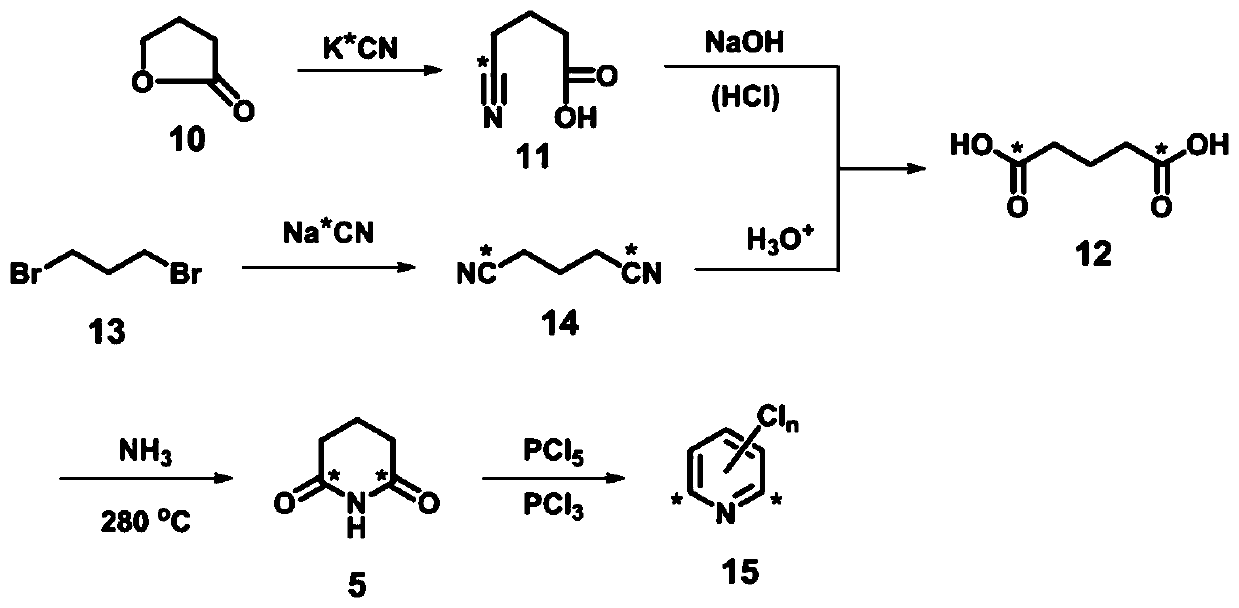

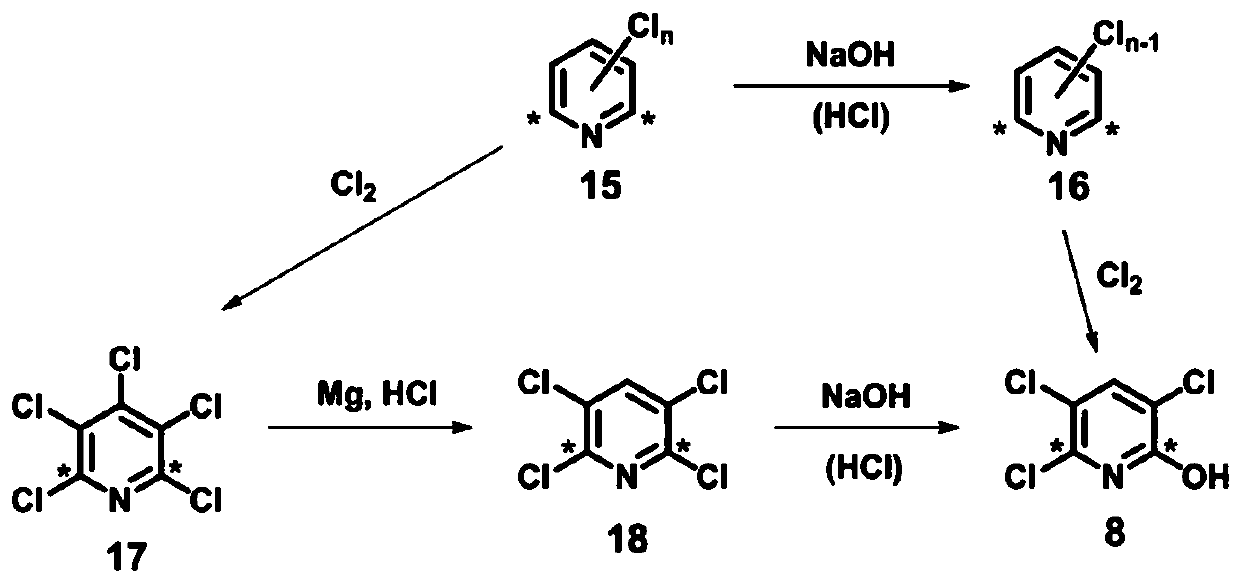

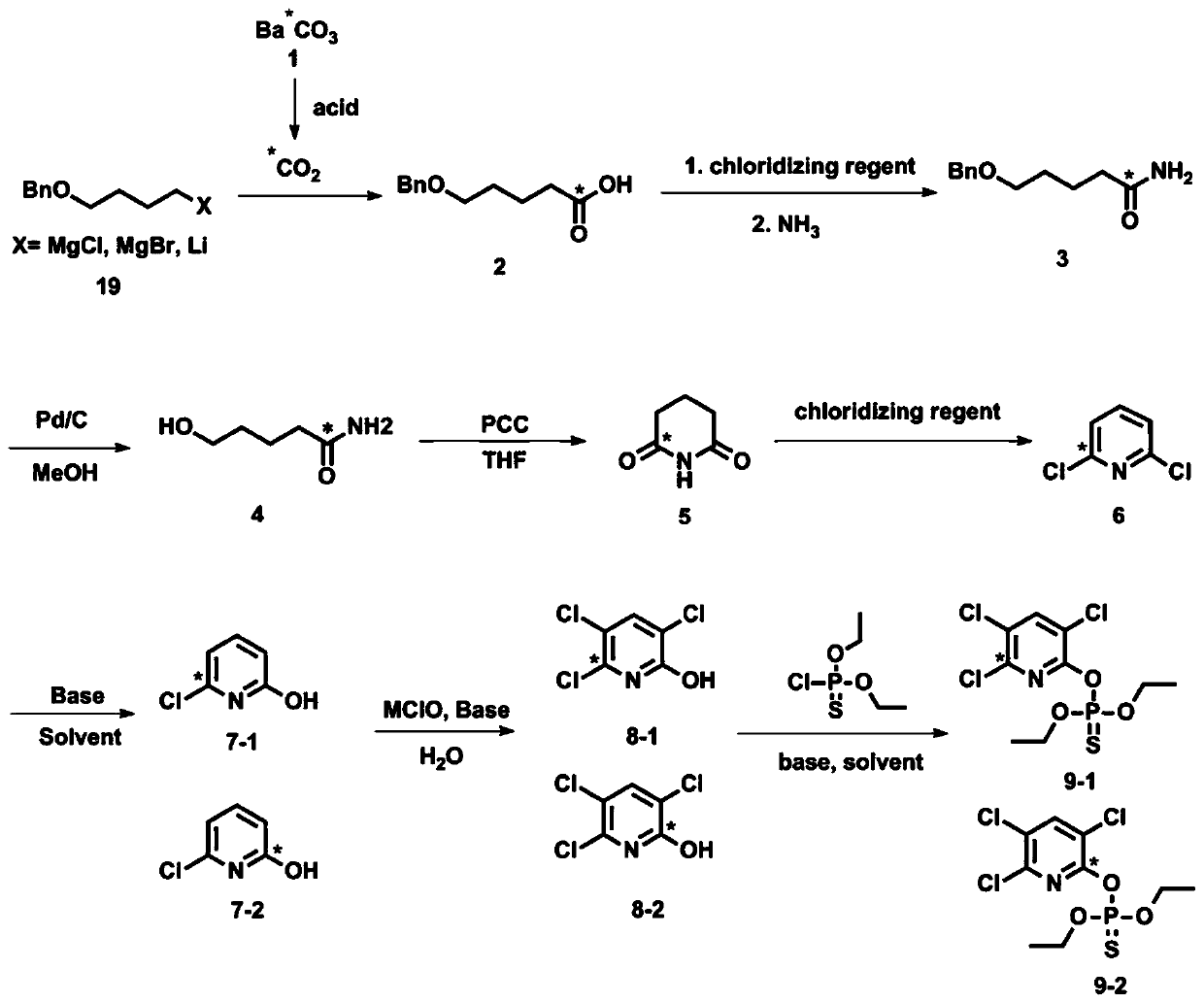

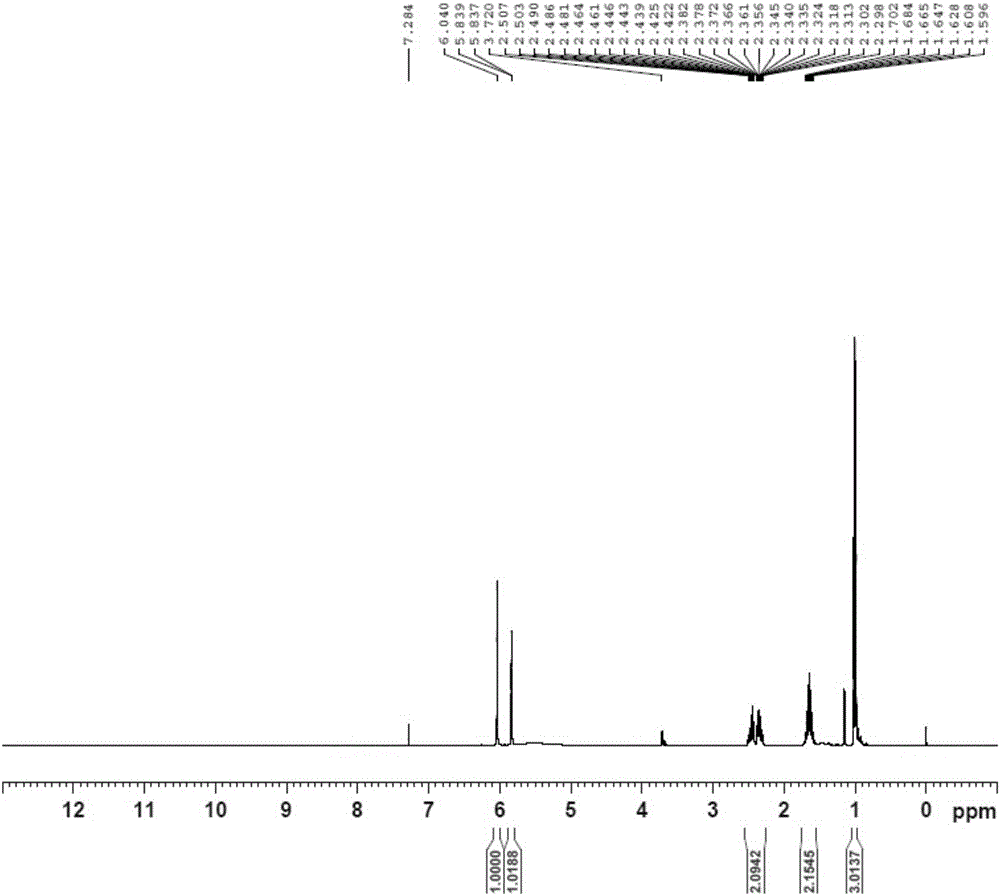

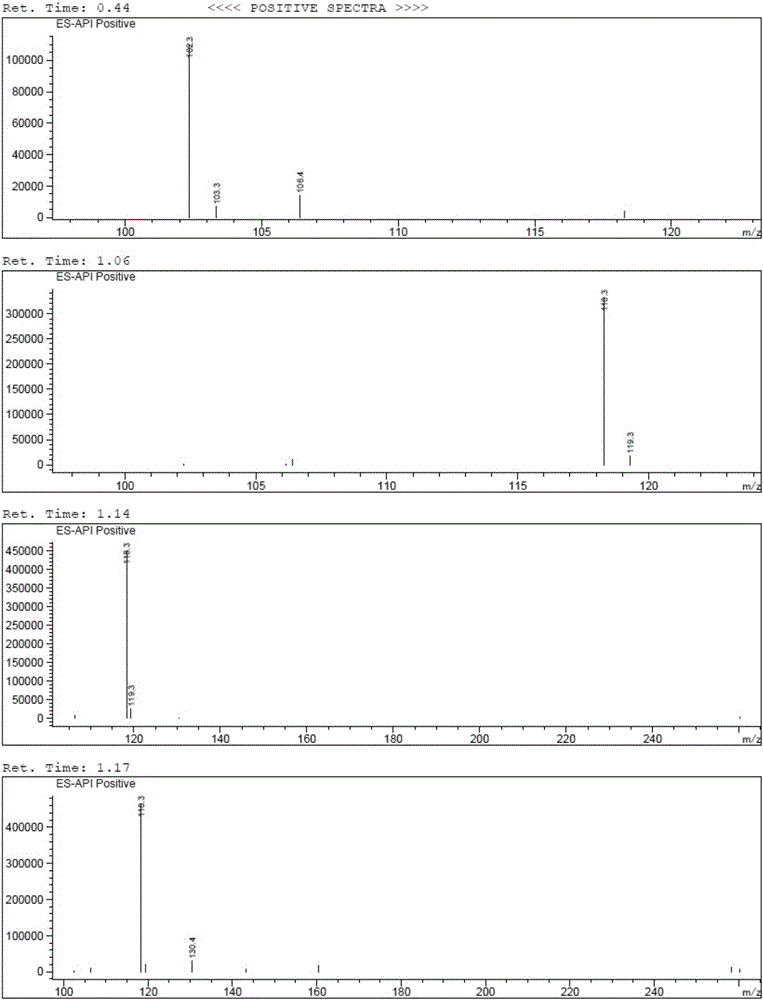

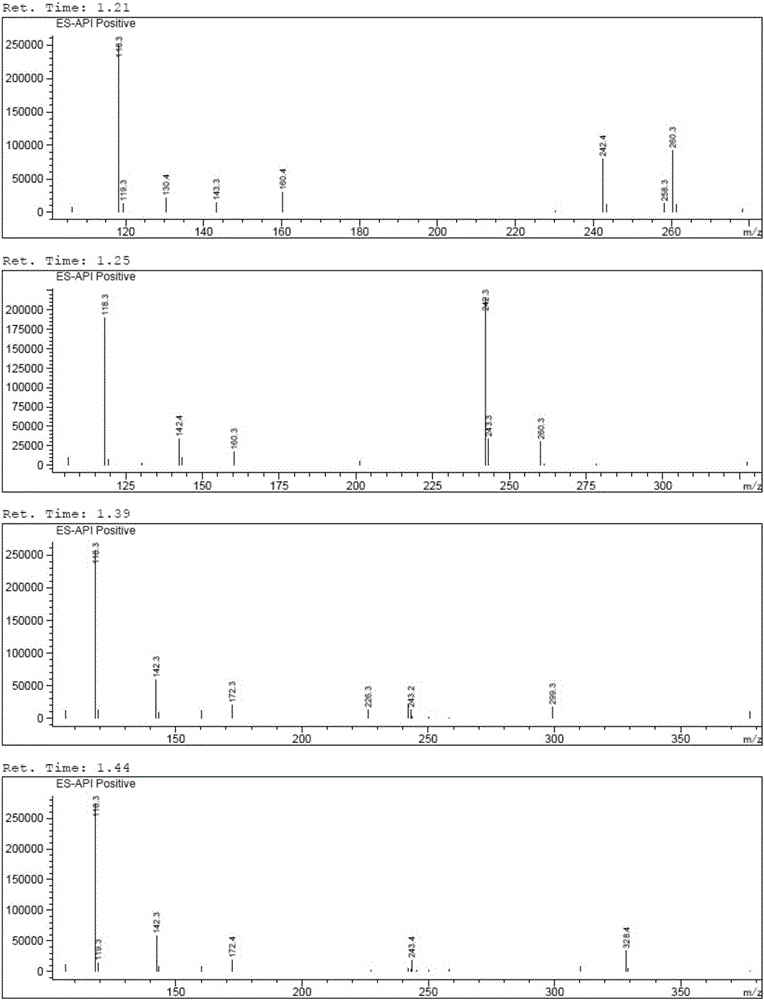

A kind of insecticide chlorpyrifos labeled with radioactive isotope carbon-14 and its synthesis method

ActiveCN108341839BNot easy to loseReduce usageGroup 5/15 element organic compoundsOrganic chemistry methodsRadioactive tracerChemical synthesis

The invention belongs to the field of radiochemical synthesis, and more specifically relates to radioisotope carbon-14 labelled pesticide chlopyrifos, and a synthesis method thereof. The synthesis method comprises following steps: a metal organic reagent is reacted with [14C] carbon dioxide so as to obtain 5-benzyloxy[carbonyl-14C] pentanoic acid; amidation, debenzylation, and cyclization reactionare adopted so as to realize conversion into [carbonyl-2, 6-14C2] glutarimide; aromatization, chlorination, and hydrolysis are adopted, and an obtained hydrolysate and diethyl thiophosphoryl chlorideare subjected to nucleophilic substitution so as to obtain the carbon-14 labelled pesticide chlopyrifos. The synthetic method is capable of avoiding defects in the prior art; the reaction raw materials are easily available; the reaction conditions are mild; production cost is low; the obtained carbon-14 labelled pesticide chlopyrifos can be taken as a radioactive tracer, can be used in tracing ofpollution evolution rules such as migration conversion, metabolism degradation, and absorption enrichment of chlopyrifos in the environment and in vivo, and can be used for providing technical support for comprehensive evaluation of the biological safety of chlopyrifos; and in addition, the synthesis method is capable of providing reference for preparation of building blocks containing C-14.

Owner:ZHEJIANG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com

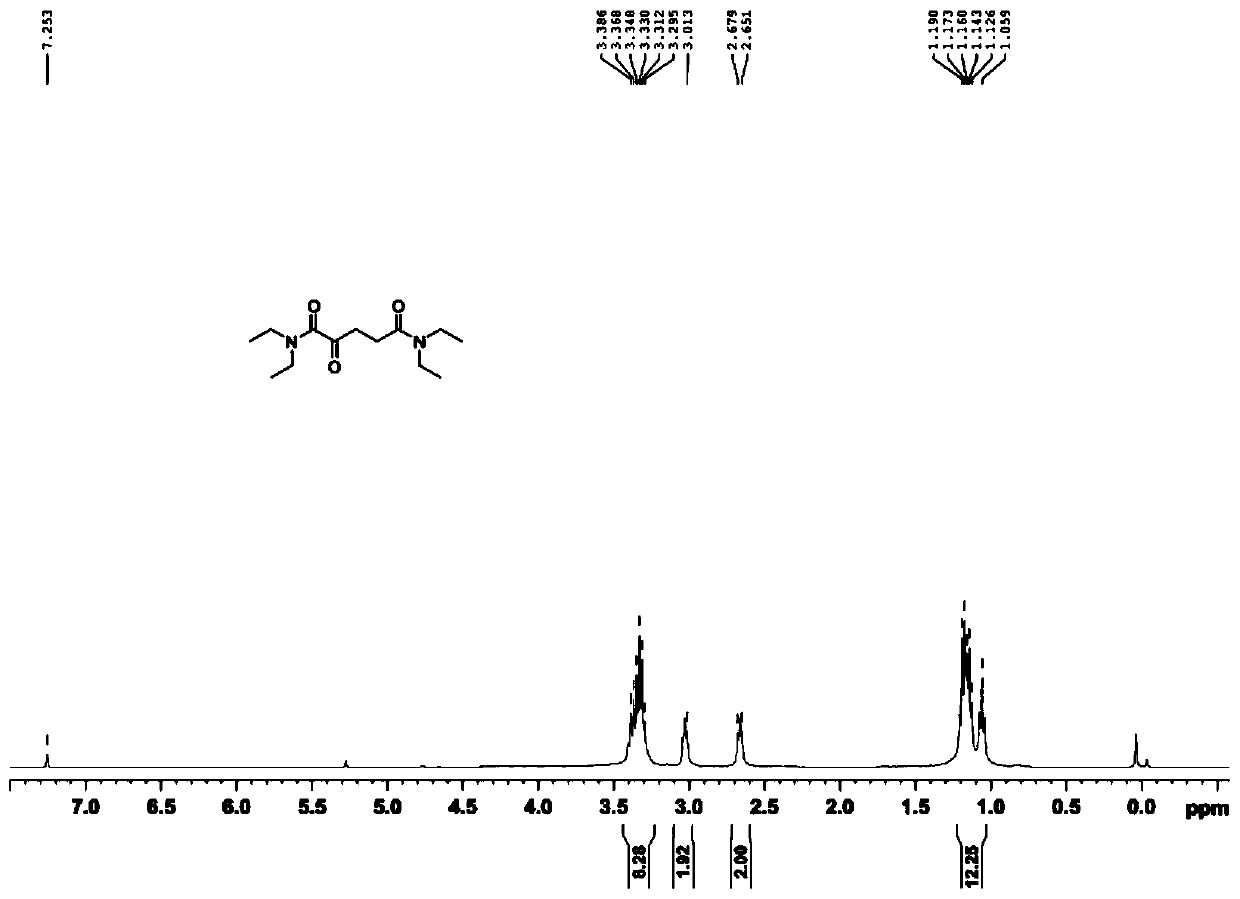

![A process for converting substituted phenyl diazonium salts into [(trifluoromethyl)thio]benzene A process for converting substituted phenyl diazonium salts into [(trifluoromethyl)thio]benzene](https://images-eureka.patsnap.com/patent_img/11a31f66-26c8-4cf8-8152-8a6b87716060/FDA0001660184740000011.png)

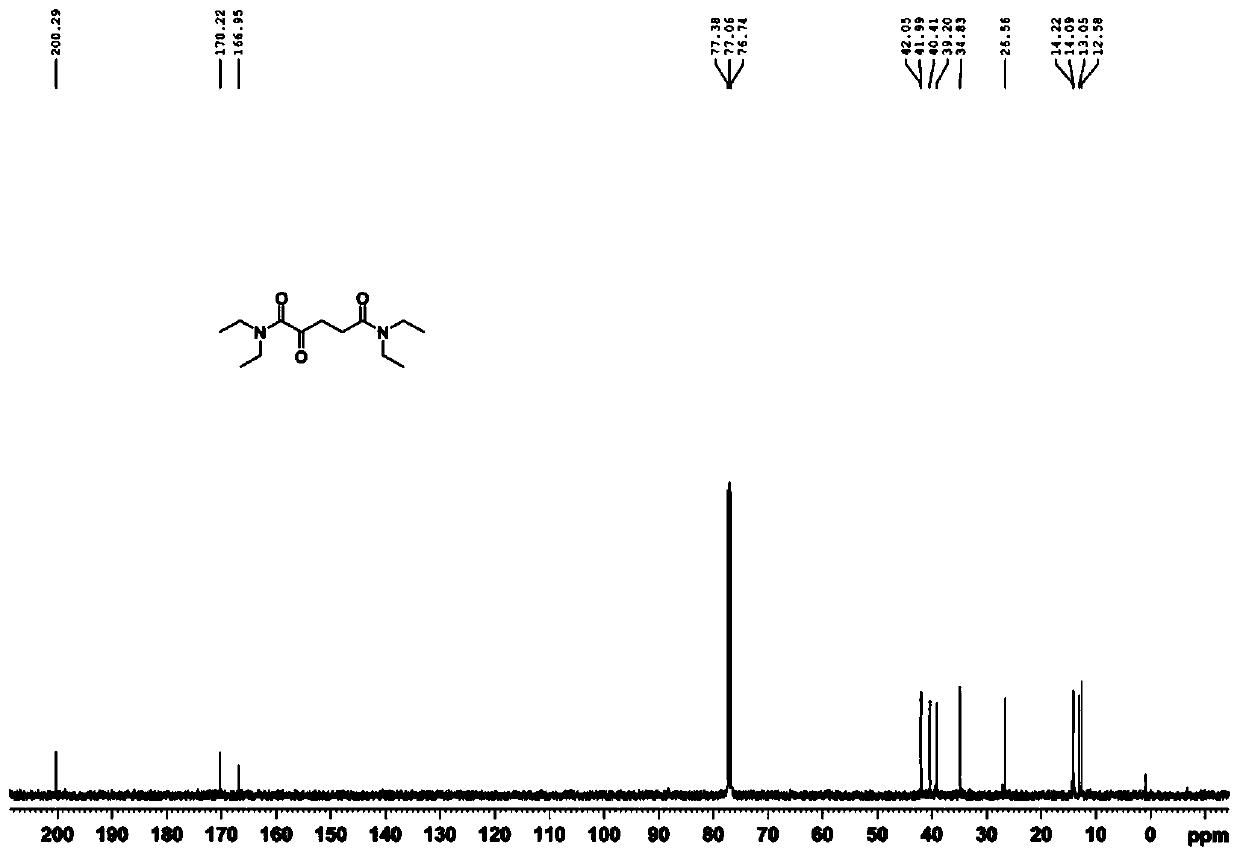

![A process for converting substituted phenyl diazonium salts into [(trifluoromethyl)thio]benzene A process for converting substituted phenyl diazonium salts into [(trifluoromethyl)thio]benzene](https://images-eureka.patsnap.com/patent_img/11a31f66-26c8-4cf8-8152-8a6b87716060/FDA0001660184740000012.png)

![A process for converting substituted phenyl diazonium salts into [(trifluoromethyl)thio]benzene A process for converting substituted phenyl diazonium salts into [(trifluoromethyl)thio]benzene](https://images-eureka.patsnap.com/patent_img/11a31f66-26c8-4cf8-8152-8a6b87716060/FDA0001660184740000021.png)