Mechanical device for production of methyl aspartate

A technology of aspartate methyl ester and mechanical device, applied in the directions of organic chemistry, preparation of organic compounds, chemical instruments and methods, etc., can solve the problems of harsh conditions, high cost, poor product quality, etc., and achieve no high temperature. High pressure reaction, high yield of finished products and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

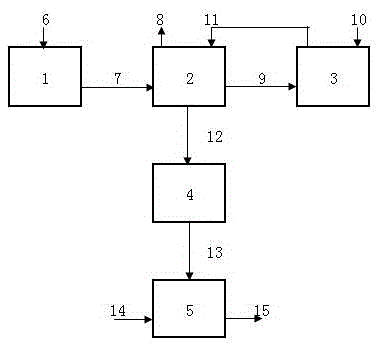

[0018] Further illustrate the specific content of using this novel device to produce methyl aspartate best embodiment below in conjunction with accompanying drawing:

[0019] 1. Add chemically pure sulfuric acid with a concentration of 30% into the first stirring tank 1 through the first raw material inlet 6 arranged on the first stirring tank, and then add pharmaceutical grade aspartic acid powder through the same inlet 6, the two raw materials The weight ratio is sulfuric acid with a concentration of 30%: aspartic acid powder = 5:5, after stirring and reacting for 2-2.5 hours at room temperature, a solid-liquid mixture of aspartic acid sulfate is obtained, and aspartic acid sulfate The solid-liquid mixture is sent into the filter 2 to filter out the liquid part through the first slurry pump and the pipeline 7 arranged between the first stirring tank 1 and the filter 2, and the liquid part is discharged through the filtrate outlet 8 arranged on the filter 2 , The obtained sol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com