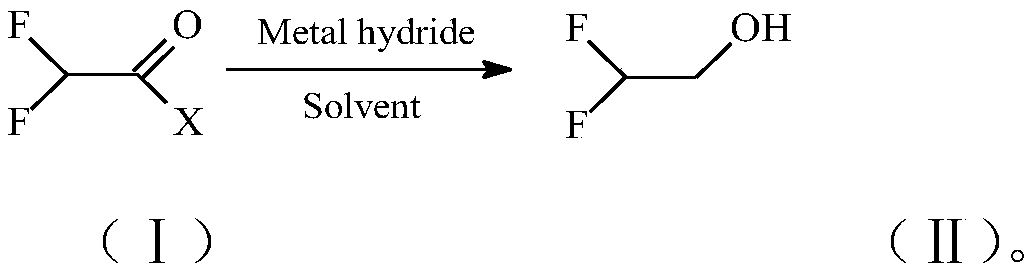

Preparation method of 2,2-difluoroethanol

A technology of difluoroethanol and difluoroacetyl halide is applied in the field of preparing 2,2-difluoroethanol, can solve the problems of high cost, low reaction yield, low yield and the like, achieves mild reaction conditions, simple process steps, high yield effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] Add 22.6g (0.6mol) of NaBH to a 1000ml reactor with magnetic stirring, thermocouple and cooling coil 4 , then add 200ml of CH 3 Oh. Stir and keep the temperature of the reactor at about -10°C, slowly feed 98.0g (1.0mol) of CF into the reactor 2 HCOF, keep the reaction temperature at -10~0℃, wait for CF 2 After the addition of HCOF, continue to stir for 1.0 h, add hydrochloric acid to adjust the pH value of the still liquid to 3-4, and terminate the reaction. The still liquid was subjected to a rectification operation to obtain the product 2,2-difluoroethanol with a yield of 96.1%.

Embodiment 2

[0044] Add 11.4g (0.3mol) of LiAlH to a 1000ml reactor with magnetic stirring, thermocouple and cooling coil 4 and 300ml of diethylene glycol dimethyl ether, stir and keep the still temperature of the reaction kettle at about -10°C. Slowly feed 58.8g (0.6mol) of CF into the reactor 2HCOF, keep the kettle temperature at about -10~0℃, wait for CF 2 After the addition of HCOF, continue to stir for 0.5h, add hydrochloric acid to adjust the pH value of the kettle liquid to 2-3, and terminate the reaction. The still liquid was subjected to a rectification operation to obtain the product 2,2-difluoroethanol with a yield of 97.8%.

Embodiment 3

[0046] NaBH 4 and substrate CF 2 The molar ratio of HCOF was changed to 0.5:1, and all the other operating conditions were the same as in Example 1. After the reaction, the still liquid was rectified to obtain the product 2,2-difluoroethanol with a yield of 91.2%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com