Method for preparing caesium-lead halide nanorod and product obtained through method

A cesium lead halide, nanorod technology, applied in the direction of lead halide, nanotechnology, etc., achieves the effects of simple operation, good crystal shape and uniform morphology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] 1.1 Add 84mg of lead iodide and 5mL of octadecene into a four-neck flask, and stir for 1h under nitrogen protection.

[0030] 1.2 Then add 1mL oleylamine and 1mL oleic acid to the mixture described in 1.1 successively, heat to 140°C after the lead iodide is completely dissolved, then add 0.4mL cesium precursor solution (cesium carbonate 0.16g, octadecene 6mL, 2.5mL of oleic acid, heated until the cesium carbonate is completely dissolved to obtain a cesium precursor solution) injected into the solution at an injection speed of 0.4mL / min, and the product was taken out after 10s of insulation reaction under the protection of nitrogen, and cesium iodide was obtained by centrifugal separation and washing lead nanorods.

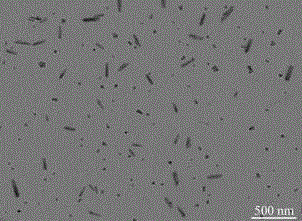

[0031] 1.3 The diameter of the obtained cesium lead iodide nanorods is 10 nm, the length is 150 nm, and the crystal form is good. The luminous rate of the product can reach 30%.

Embodiment 2

[0033] 2.1 Add 84 mg of lead iodide and 5 mL of octadecene into a four-neck flask, and stir for 1 h under nitrogen protection.

[0034] 2.2 Then add 1mL oleylamine and 1mL oleic acid to the mixture described in 2.1 successively, heat to 150°C after the lead iodide is completely dissolved, then add 0.4mL cesium precursor solution (cesium carbonate 0.16g, octadecene 6mL, 2.5mL of oleic acid, heated until the cesium carbonate is completely dissolved to obtain a cesium precursor solution) injected into the solution at an injection speed of 0.4mL / min, kept warm and reacted for 10s under nitrogen protection, took out the product, and obtained rod-shaped cesium iodide by centrifugal separation and washing lead nanorods.

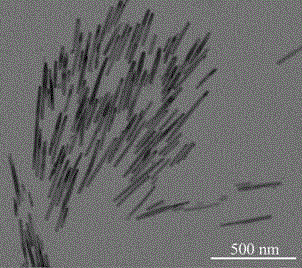

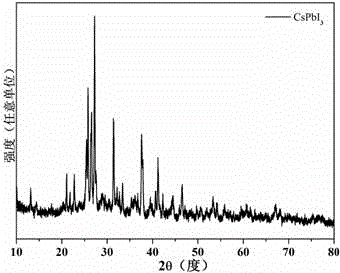

[0035] 2.3 The cesium lead iodide nanorods obtained in this example have a diameter of 15nm, a length of 300nm, and a luminous efficiency of up to 30%, indicating that the crystal form is good, such as figure 1 shown.

Embodiment 3

[0037] 3.1 Add 84 mg of lead iodide and 5 mL of octadecene into a four-neck flask, and stir for 1 h under nitrogen protection.

[0038] 3.2 Then add 1mL oleylamine and 1mL oleic acid to the mixture described in 3.1 successively, heat to 160°C after the lead iodide is completely dissolved, then add 0.4mL cesium precursor solution (cesium carbonate 0.16g, octadecene 6mL, 2.5 mL of oleic acid, heated until the cesium carbonate is completely dissolved to obtain a cesium precursor solution) injected into the solution at an injection speed of 0.4 mL / min, kept warm and reacted for 10 seconds under the protection of nitrogen, then took out the product, and cesium lead iodide was obtained by centrifugal separation and washing Nano stave.

[0039] 3.3 The cesium lead iodide nanorods obtained in this example have a diameter of 16 nm, a length of 330 nm, and a luminous efficiency of up to 30%, indicating that the crystal form is good.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com