Low-temperature-resistant water-based automobile coating, and preparation method and device thereof

A low-temperature-resistant, water-based technology, applied in anti-fouling/underwater coatings, mixing methods, anti-corrosion coatings, etc., can solve the problems of slow drying speed, easy cracks, and poor frost resistance of water-based coatings, so as to prevent paint splashing and surface damage. The effect of small tension and not easy to bubble

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

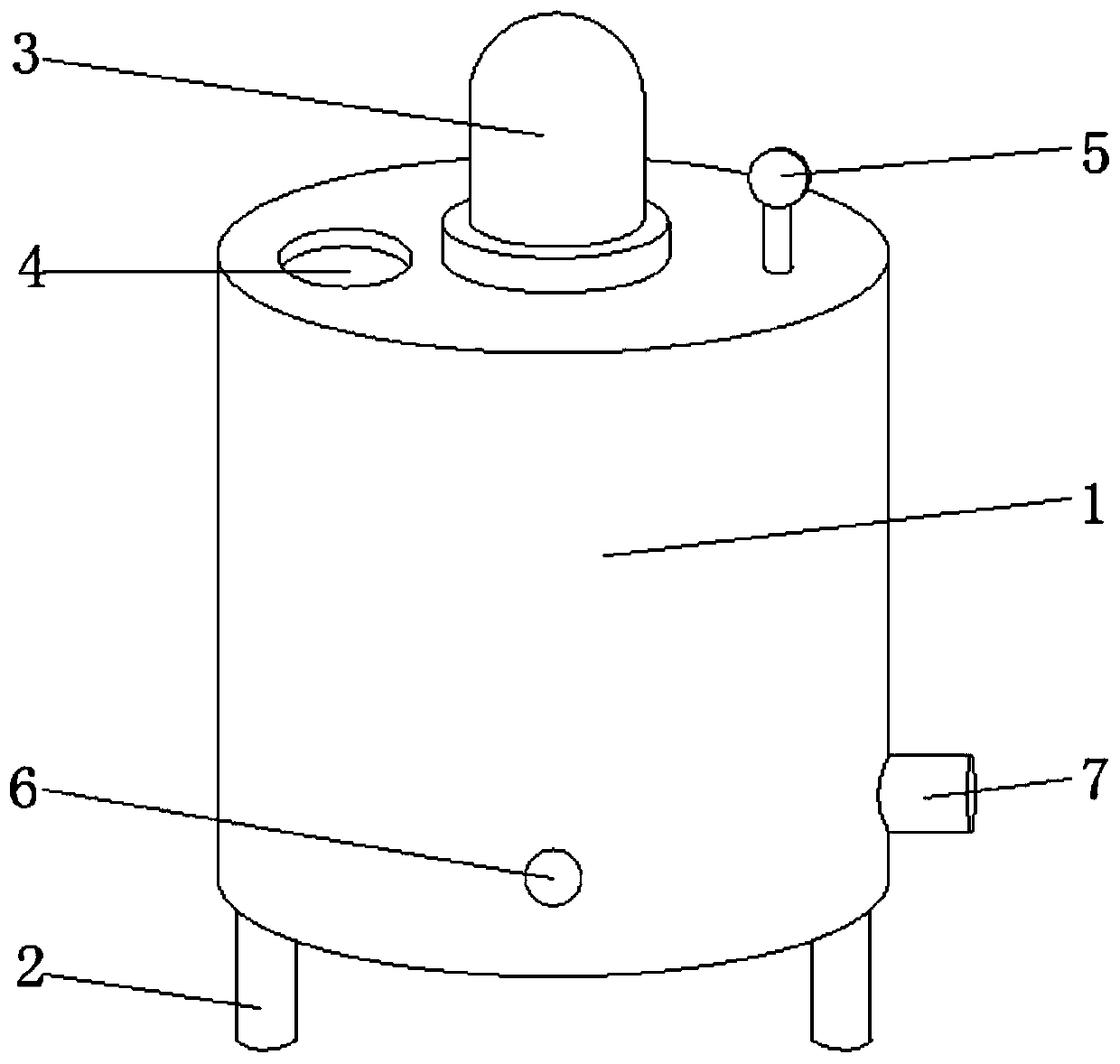

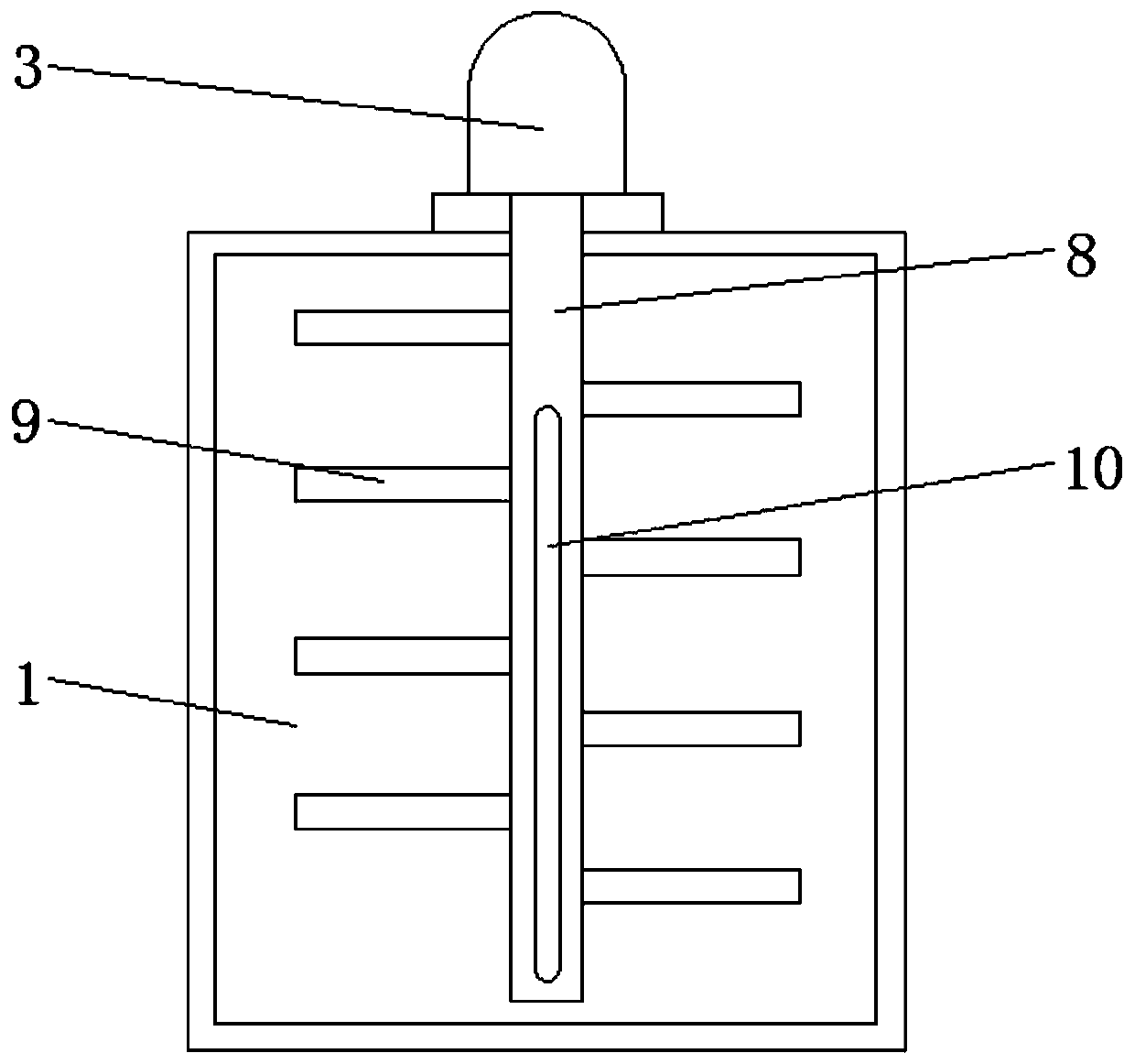

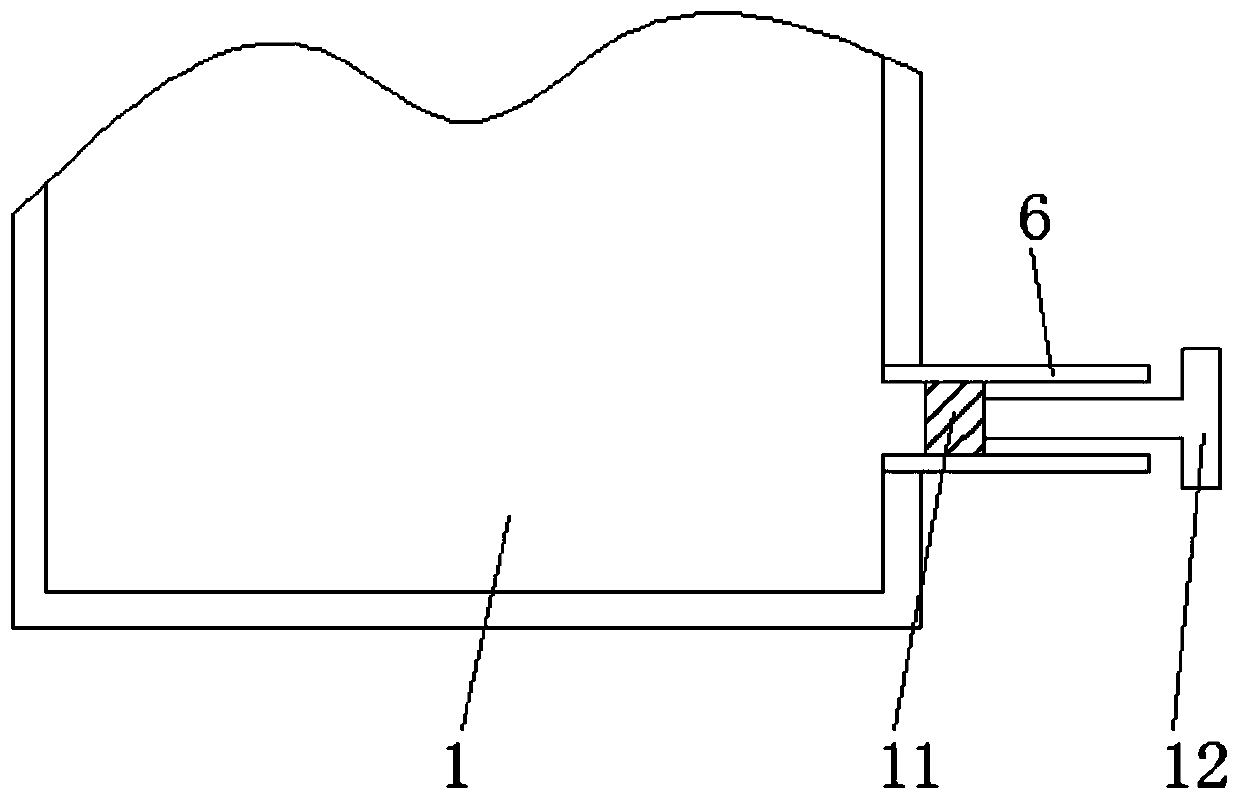

[0028] see Figure 1 to Figure 3 , the low-temperature-resistant water-based automotive coating provided by the present embodiment is made of the following parts by weight: 60 parts of water-based acrylic emulsion, 3 parts of film-forming aids, 0.5 part of defoamer, 0.3 part of wetting and leveling agent, 2 parts of rheology additive, 1.5 parts of surface control additive, 0.1 part of matting agent, 0.05 part of preservative, 0.05 part of pH regulator, 10 parts of pigment, and the balance of water.

[0029] The preparation method of the aforementioned low-temperature-resistant water-based automotive paint, it may further comprise the steps:

[0030] S1: Add water-based acrylic emulsion, pigment and water into the mixing equipment for stirring, and the stirring time is 30 minutes;

[0031] S2: Add defoamer, wetting and leveling agent, rheology additive, surface control additive, matting agent, preservative, pH regulator, and film-forming additive composed of propylene glycol e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com