Supporting formwork-free thick coating type cement-based repair mortar and construction method thereof

A repairing mortar and coating type technology, which is applied in building maintenance, construction, building construction, etc., can solve problems such as construction speed and quality of structure repairing projects, and achieve improved construction efficiency and overall quality, good dispersion, and production convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

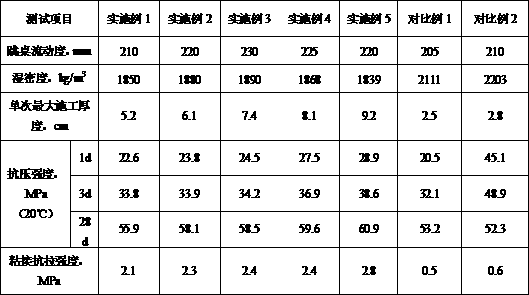

Examples

Embodiment 1

[0043] A kind of thick-coated cement-based repair mortar for free formwork, which is mixed with the following components in parts by weight:

[0044] Ordinary Portland cement 36 parts,

[0045] 41.77 parts of river sand,

[0046] Expansion component 10 parts,

[0047] 2 parts of wet density control components,

[0048] Anti-sagging component 3 parts,

[0049] 3 parts rubber powder,

[0050] Thickener 0.2 part,

[0051] 2 parts retarding component,

[0052] Early strength component 2 parts,

[0053]Chemical staple fiber 0.03 parts.

[0054] Among them, the river sand is a mixture of 0-0.3mm and 0.3-0.6mm river sand with a mass ratio of 1:2; the wet density control component is a hydrophobic silicon dioxide defoamer and triterpene saponins with a mass ratio of 1:3. Aerosol mixture. The anti-sag component is 500kg / m 3 A mixture of encrypted silica fume, sodium bentonite and metakaolin at a weight ratio of 1:1:1. The rubber powder is redispersible vinyl acetate / ethylene...

Embodiment 2

[0056] A kind of thick-coated cement-based repair mortar for free formwork, which is mixed with the following components in parts by weight:

[0057] Ordinary Portland cement 36 parts,

[0058] 36.57 parts of river sand,

[0059] Expansion component 10 parts,

[0060] 2 parts of wet density control components,

[0061] Anti-sagging component 6 parts,

[0062] 5 parts rubber powder,

[0063] Thickener 0.4 part,

[0064] 2 parts retarding component,

[0065] Early strength component 2 parts,

[0066] Chemical staple fiber 0.03 parts.

[0067] Among them, the river sand is a mixture of 0-0.3mm and 0.3-0.6mm river sand with a mass ratio of 1:2; the wet density control component is a hydrophobic silicon dioxide defoamer and triterpene saponins with a mass ratio of 1:3. Aerosol mixture. The anti-sag component is 500kg / m 3 A mixture of encrypted silica fume, sodium bentonite and metakaolin at a weight ratio of 1:1:1. The rubber powder is redispersible vinyl acetate / ethylen...

Embodiment 3

[0069] A kind of thick-coated cement-based repair mortar for free formwork, which is mixed with the following components in parts by weight:

[0070] Ordinary Portland cement 35 parts,

[0071] 35.77 parts of river sand,

[0072] Expansion component 15 parts,

[0073] 3 parts of wet density control components,

[0074] Anti-sagging component 3 parts,

[0075] 3 parts rubber powder,

[0076] Thickener 0.2 part,

[0077] 3 parts of retarding component,

[0078] Early strength component 2 parts,

[0079] Chemical staple fiber 0.03 part.

[0080] Among them, the river sand is a mixture of 0-0.3mm and 0.3-0.6mm river sand with a mass ratio of 1:3; the wet density control component is a hydrophobic silicon dioxide defoamer and triterpene saponins with a mass ratio of 1:2. Aerosol mixture. The anti-sag component is 500kg / m 3 A mixture of encrypted silica fume, sodium bentonite and metakaolin at a weight ratio of 1:1:1. The rubber powder is redispersible vinyl acetate / ethyl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com