Method and equipment for recovering protein from starch crop processing wastewater

A technology for processing wastewater and starch, which is applied in the field of protein recovery, can solve the problems of high cost and difficulty in maintaining biological activity, and achieve the effects of low cost, high degree of automation and high separation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] This embodiment provides a method for recovering protein from starch crop processing wastewater, including:

[0045] (1) Disperse the silicon dioxide particles in the dodecyl dimethyl betaine solution, adjust the pH to 4.9, stir, centrifuge and freeze-dry; the silicon dioxide particles and the dodecyl dimethyl betaine molar The ratio is 2:1;

[0046] (2) Add the modified silicon dioxide nanoparticles obtained in step (1) to starch crop processing wastewater, feed gas to generate foam, the concentration of silicon dioxide nanoparticles is 500mg / L, and the flow rate of feeding gas is 250mL / L min;

[0047] (3) Ultrasonic defoaming the foam generated in step (2), spray-drying, and then ultrafine pulverization, and the particle size of the crude protein extract powder after ultrafine pulverization is 100 nm.

[0048] (4) The protein crude extract powder after ultrafine pulverization is triboelectrically charged to make the protein positively charged, and the starch and oth...

Embodiment 2

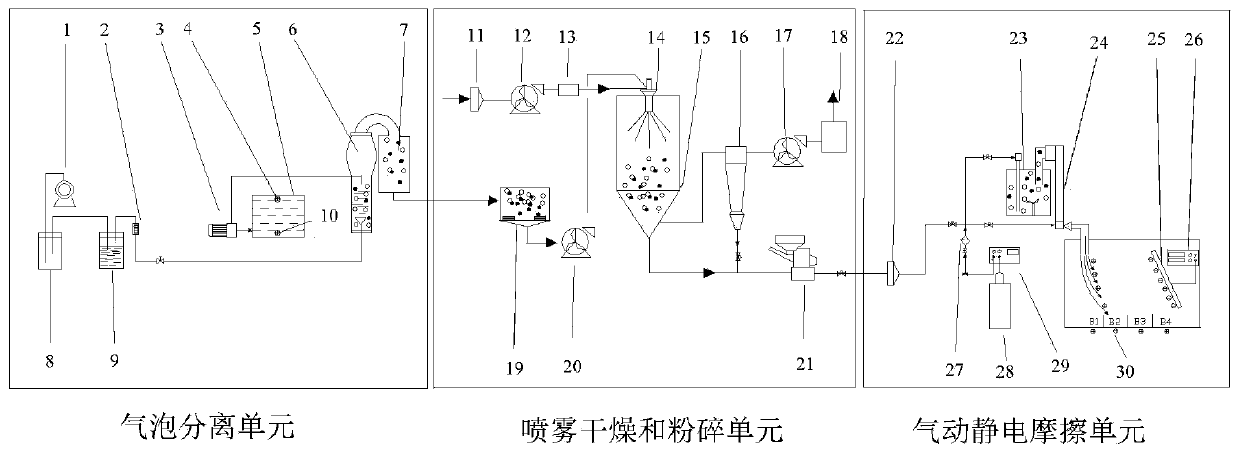

[0051] figure 1 For this embodiment, a kind of equipment for recovering protein from starch crop processing wastewater is provided for implementing the method in Example 1, such as figure 1 As shown, starch crop protein extraction equipment includes:

[0052] Bubble separation unit, spray drying and crushing unit and pneumatic electrostatic friction unit;

[0053] The bubble separation unit comprises a starch crop processing wastewater storage tank 5, a foam separator 6 and a foam collector 7, and the starch crop processing wastewater storage tank 5 is provided with a feed port 4 and a discharge port 10, and the starch crop is fed by a feed pump 3 The processing wastewater is transported to the foam separator 6 through pipelines; the foam separator 6 is composed of an upper part of an elliptical sphere connected with a lower part of a cylinder, and the air inlet end is connected with an air compressor 1, a gas cylinder 8, and a rotor in sequence. The flow meter 2 and the air...

Embodiment 3

[0060] This embodiment provides a method for recovering protein from starch crop processing wastewater, combining figure 1 , the specific steps of the method are as follows:

[0061] (1) In the bubble separation unit, the potato processing wastewater containing modified silicon dioxide nanoparticles in the starch crop processing wastewater storage tank 5 enters the foam separator 6 through the feed pump 3, wherein the modified silicon dioxide nanoparticles and The concentration is 500mg / L. The gas produced by the air compressor 1 passes through the gas cylinder 8 and the air humidification cylinder 9 in turn. The flow rate of the gas is controlled by the rotameter 2 to be 250mL / min. In the foam separator 6, the foam produced by the potato processing wastewater under the action of the gas passes through the continuous The expansion and contraction flow to the spray drying and crushing unit.

[0062] Among them, the preparation method of modified silica nanoparticles is as fol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com