Free radical controllable-release defect coordination metal-organic framework, and preparation method and application thereof

A technology of coordinating metals and organic frameworks, applied in water treatment parameter control, chemical instruments and methods, organic compounds/hydrides/coordination complex catalysts, etc. , Unable to achieve controllable release of free radicals, single content of catalytic active sites, etc., to achieve the effects of easy process production, efficient treatment, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

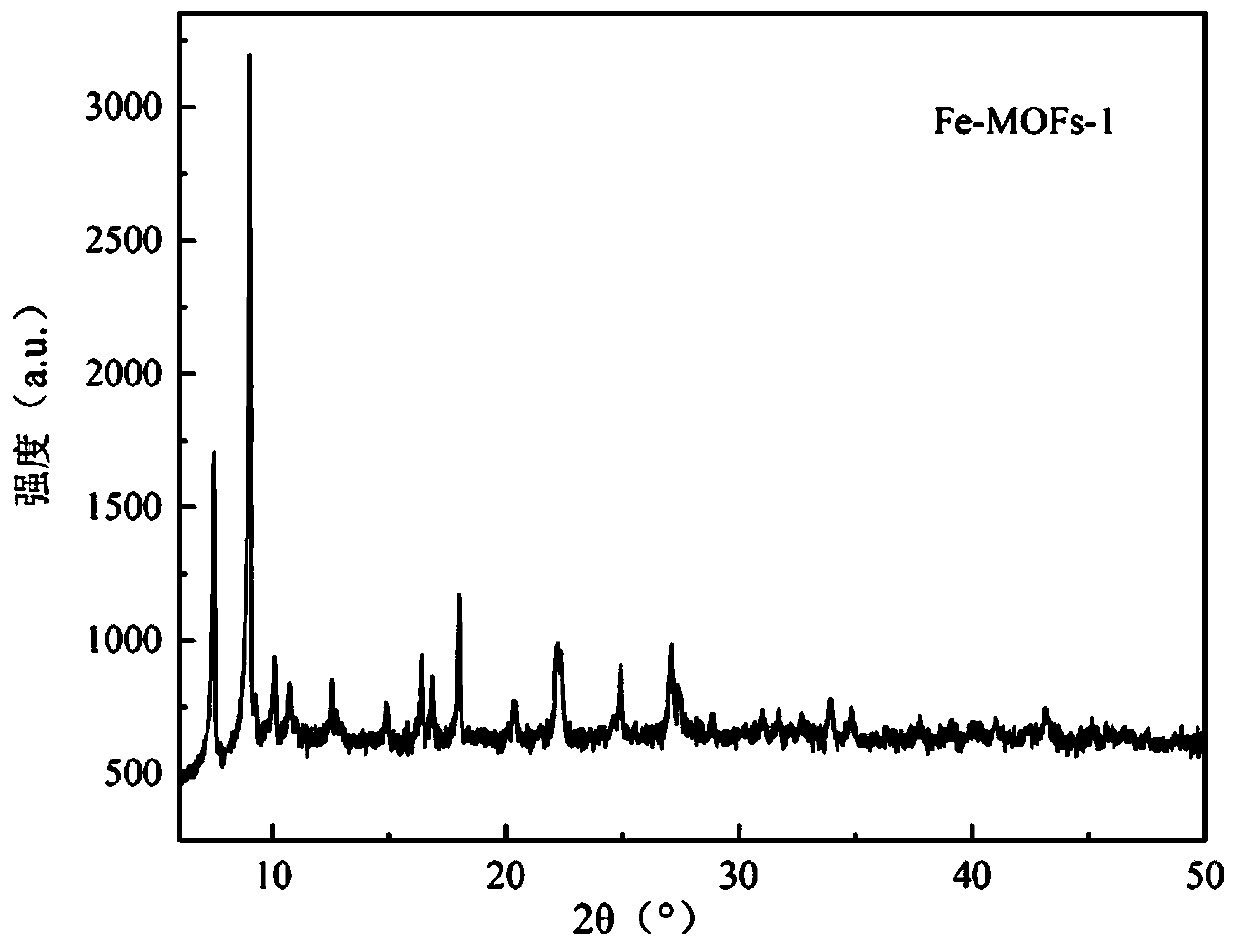

Embodiment 1

[0033] This example provides a method for preparing a defect-coordinated metal-organic framework with controlled release of free radicals, which includes the following steps:

[0034] (1) Dissolve 0.5 mmol of ferrous chloride tetrahydrate and 0.5 mmol of terephthalic acid in 130 mmol of N,N-dimethylformamide and stir for 20 minutes to obtain a mixed solution;

[0035] (2) Add 10 mmol acetic acid to the mixed solution in step (1) and continue stirring under N 2 Deoxygenate in the atmosphere for 30 minutes to obtain a reaction mixture, transfer the reaction mixture to a 25 mL lined polytetrafluoroethylene autoclave reactor and react at 150°C for 12 hours to obtain a post-reaction mixture;

[0036] (3) After the reaction is finished, wait for the reaction kettle to cool down to room temperature and use a high-speed centrifuge to analyze the product, and use 120mL N,N-dimethylformamide to wash the solid product twice, each washing time is 45min, and continue to use methanol to was...

Embodiment 2

[0041] This example provides a method for preparing a defect-coordinated metal-organic framework with controlled release of free radicals, which includes the following steps:

[0042] (1) Dissolve 0.5 mmol of ferrous chloride tetrahydrate and 0.5 mmol of terephthalic acid in 260 mmol of N,N-dimethylformamide and stir for 20 minutes to obtain a mixed solution;

[0043] (2) Add 15 mmol n-butyric acid to the mixed solution in step (1) and continue to stir for 20 min and 2 Deoxygenate in the atmosphere for 30 minutes to obtain a reaction mixture, transfer the reaction mixture to a 25 mL lined polytetrafluoroethylene autoclave reactor and react at 150°C for 12 hours to obtain a post-reaction mixture;

[0044](3) After the reaction is finished, wait for the reaction kettle to cool down to room temperature and use a high-speed centrifuge to analyze the product, and use 120mL N,N-dimethylformamide to wash the solid product twice, each washing time is 45min, and continue to use methano...

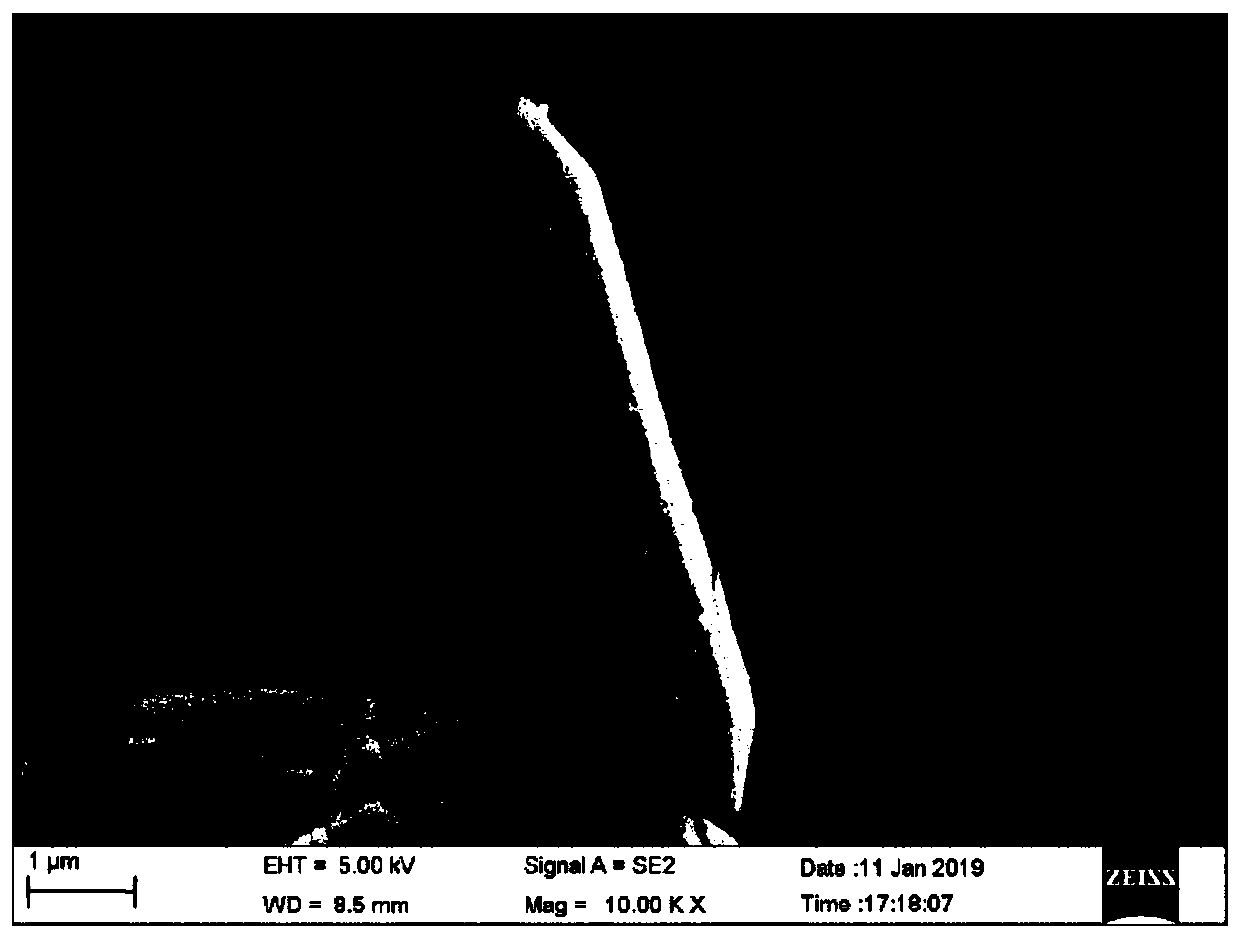

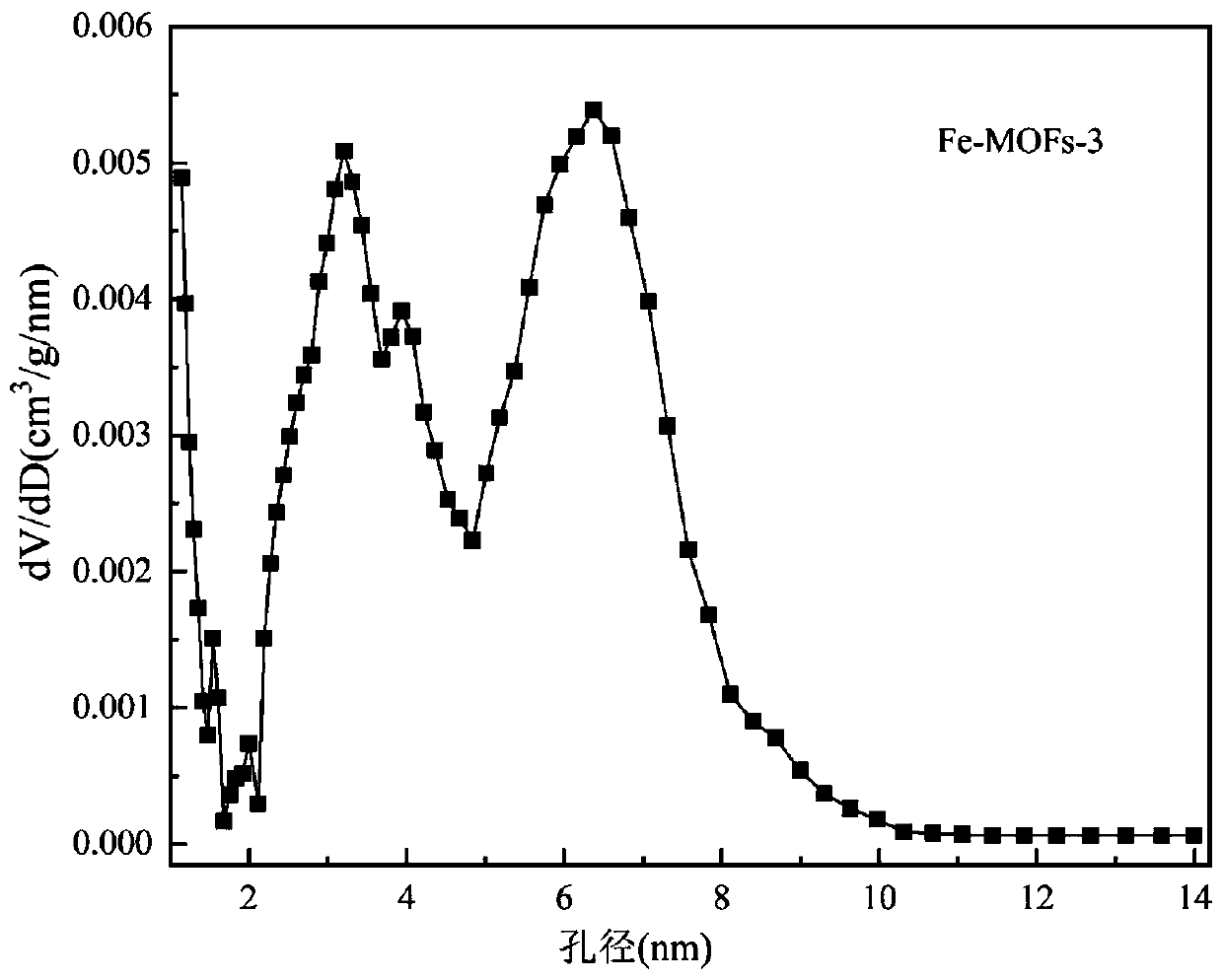

Embodiment 3

[0049] This example provides a method for preparing a defect-coordinated metal-organic framework with controlled release of free radicals, which includes the following steps:

[0050] (1) Dissolve 0.5 mmol ferrous chloride tetrahydrate and 0.5 mmol terephthalic acid in 320 mmol N,N-dimethylformamide and stir for 20 minutes to obtain a mixed solution;

[0051] (2) Add 20 mmol n-octanoic acid to the mixed solution in step (1) and continue stirring for 20 min and 2 Deoxygenate in the atmosphere for 30 minutes to obtain a reaction mixture, transfer the reaction mixture to a 25 mL lined polytetrafluoroethylene autoclave reactor and react at 150°C for 12 hours to obtain a post-reaction mixture;

[0052] (3) After the reaction is finished, wait for the reaction kettle to cool down to room temperature and use a high-speed centrifuge to analyze the product, and use 120mL N,N-dimethylformamide to wash the solid product twice, each washing time is 45min, and continue to use methanol to w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com