High-efficiency flame-retardant ceramic particle water-based thermal insulation coating and preparation method thereof

A technology of ceramic particles and heat-insulating coatings, applied in anti-corrosion coatings, fire-resistant coatings, coatings, etc., can solve problems that affect the heat-insulation effect of heat-insulating coatings, coatings do not have flame-retardant properties, and the proportion of functional powders is reduced. , to achieve good suspension and easy dispersibility, good storage stability, and reduce the effect of film-forming temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

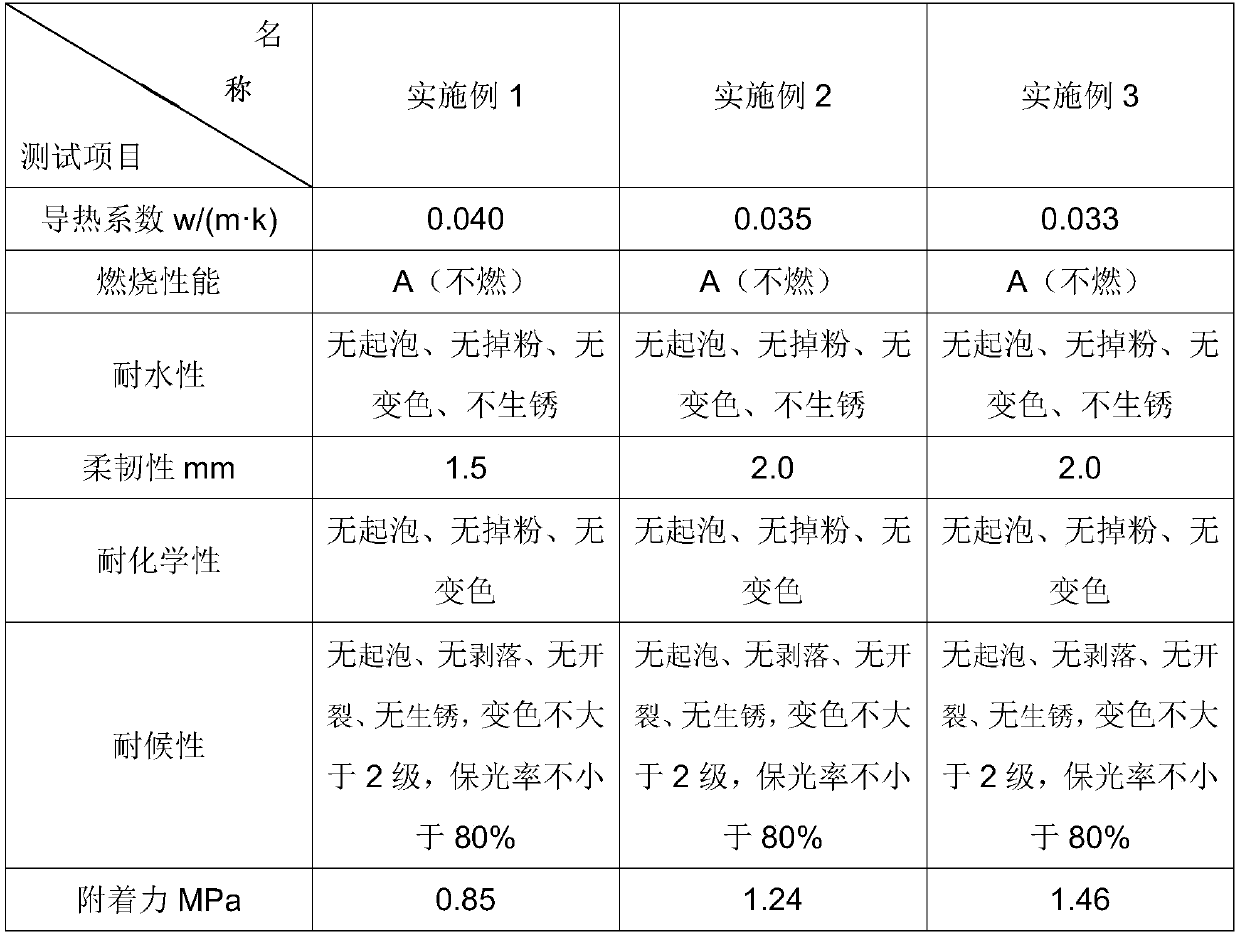

Embodiment 1

[0046] A high-efficiency flame-retardant ceramic particle water-based heat-insulating coating is composed of liquid component I, liquid component II and solid component in a mass ratio of 7.0:0.4:3.0.

[0047] Liquid component I, by mass percentage, includes the following components: 35.0% of acrylic ester emulsion, 1.5% of alcohol ester dodecane, 0.5% of 2-amino-2-methyl-1-propanol, and 0.5% of defoamer , wetting agent 1.0%, leveling agent 0.5%, dispersant 4.0%, liquid flame retardant 10.0% and water 47.0%.

[0048] The liquid component II includes the following substances in terms of mass percentage: 50% thickener and 50% water.

[0049] The solid components, in terms of mass percentage, include the following substances: 20.0% talc powder, 15.0% mica powder, 15.0% titanium dioxide powder, 20.0% heat insulating powder, and 30.0% hollow ceramic particles.

[0050] The acrylic emulsion is an alcohol-acrylic emulsion, or a styrene-acrylic emulsion, or a silicon-acrylic emulsion...

Embodiment 2

[0059] A high-efficiency flame-retardant ceramic particle water-based heat-insulating coating is composed of liquid component I, liquid component II and solid component in a mass ratio of 7.0:0.3:3.5.

[0060] Liquid component I, by mass percentage, includes the following components: 45.0% of acrylic ester emulsion, 2.2% of alcohol ester dodecane, 1.0% of 2-amino-2-methyl-1-propanol, and 0.8% of defoamer , wetting agent 1.5%, leveling agent 1.0%, dispersant 5.0%, liquid flame retardant 15.0% and water 28.5%.

[0061] The liquid component II includes the following substances in terms of mass percentage: 50% thickener and 50% water.

[0062] The solid components, in terms of mass percentage, include the following substances: 15.0% talc powder, 10.0% mica powder, 15.0% titanium dioxide powder, 15.0% heat insulating powder, and 45.0% hollow ceramic particles.

[0063] The acrylic emulsion is an alcohol-acrylic emulsion, or a styrene-acrylic emulsion, or a silicon-acrylic emulsion...

Embodiment 3

[0072] A high-efficiency flame-retardant ceramic particle water-based heat-insulating coating is composed of liquid component I, liquid component II and solid component in a mass ratio of 7.0:0.2:4.0.

[0073] Liquid component I, by mass percentage, includes the following components: 55.0% acrylic ester emulsion, 3.0% alcohol ester dodecane, 1.5% 2-amino-2-methyl-1-propanol, and 1.0% defoamer , wetting agent 2.0%, leveling agent 1.5%, dispersant 6.0%, liquid flame retardant 20.0% and water 10.0%.

[0074] The liquid component II includes the following substances in terms of mass percentage: 50% thickener and 50% water.

[0075] The solid components, in terms of mass percentage, include the following substances: 10.0% talc powder, 6.0% mica powder, 6.0% titanium dioxide powder, 18.0% heat insulating powder, and 60.0% hollow ceramic particles.

[0076] The acrylic emulsion is an alcohol-acrylic emulsion, or a styrene-acrylic emulsion, or a silicon-acrylic emulsion. The defoame...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com