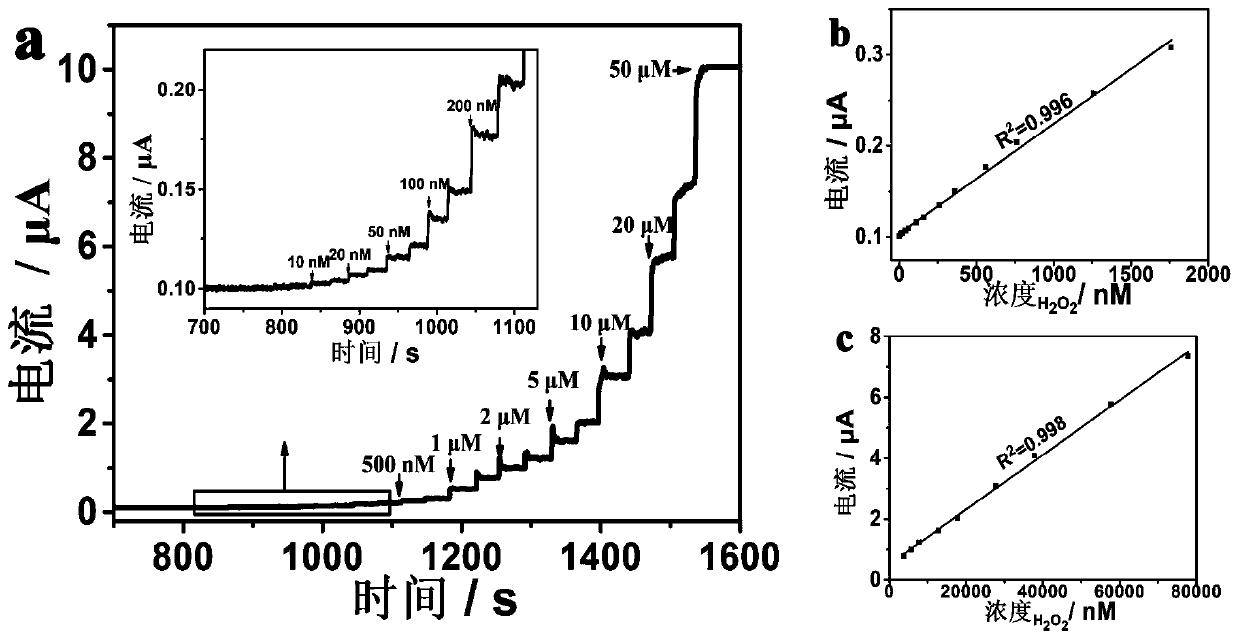

Simple preparation method of transparent electrode of ultralow-concentration hydrogen peroxide sensor

A transparent electrode, ultra-low concentration technology, applied in the field of chemical sensors, can solve problems such as inability to detect hydrogen peroxide, and achieve the effects of avoiding complex transfer processes, simple preparation methods, and strong anti-interference performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

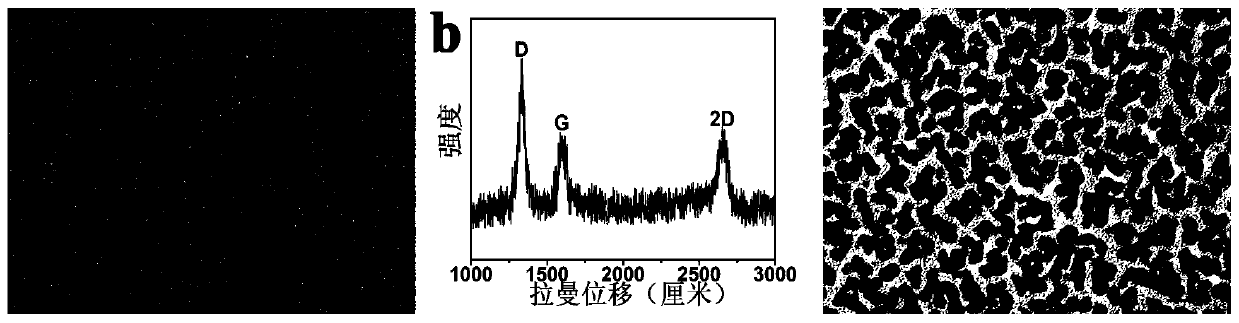

[0034] A simple and convenient preparation method for a transparent electrode of an ultra-low concentration hydrogen peroxide sensor, comprising the following steps:

[0035] (1) Use methane as the carbon source gas, argon as the carrier gas, and hydrogen as the reducing gas to form a mixed gas, pass it into the chemical vapor deposition equipment, and use the normal pressure (one atmospheric pressure) chemical vapor deposition method at a temperature of 1000°C Deposit and grow graphene on the surface of quartz glass for 3h to prepare graphene on quartz glass; the volume ratio of the argon, hydrogen and carbon source gas is 30:5:1, and the flow rate of the mixed gas is 300 sccm.

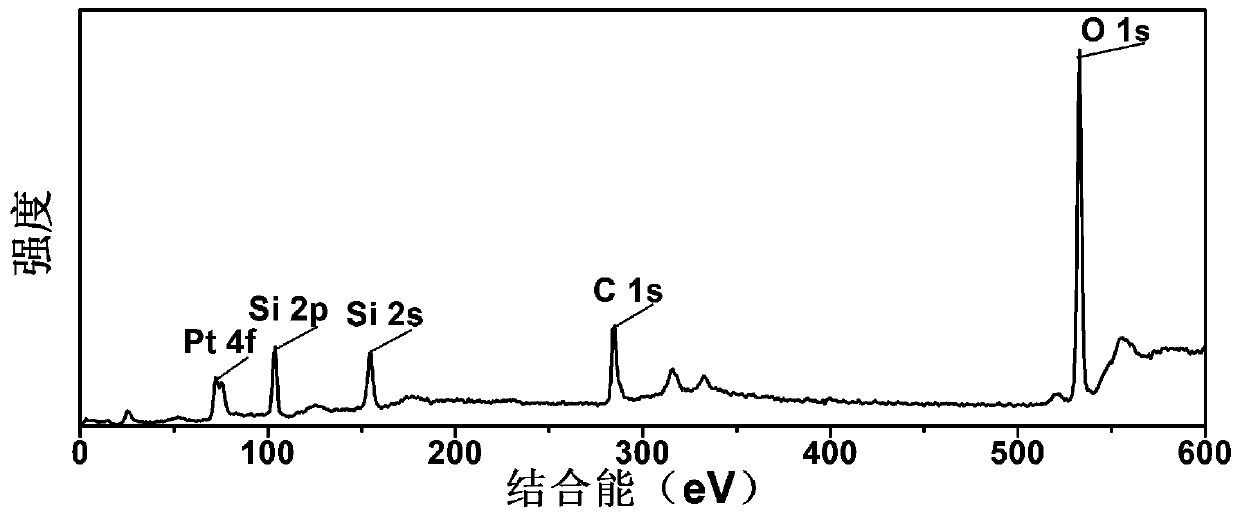

[0036](2) With platinum sheet (purity 99.99wt%) as sputtering target, using vacuum magnetron sputtering equipment, control sputtering pressure 0.3Pa, sputtering power 200W, sputtering time 1min, sputtering temperature is room temperature, in quartz Platinum nanoparticles were sputtered on the surface...

Embodiment 2

[0046] A simple and convenient preparation method for a transparent electrode of an ultra-low concentration hydrogen peroxide sensor, comprising the following steps:

[0047] (1) Use methane as the carbon source gas, argon as the carrier gas, and hydrogen as the reducing gas to form a mixed gas, pass it into the chemical vapor deposition equipment, and use the normal pressure (one atmospheric pressure) chemical vapor deposition method at a temperature of 1050°C Deposit and grow graphene on the surface of quartz glass for 2h to prepare graphene on quartz glass; the volume ratio of the argon, hydrogen and carbon source gas is 30:5:1, and the flow rate of the mixed gas is 400 sccm.

[0048] (2) With platinum sheet (purity 99.99wt%) as sputtering target, using vacuum magnetron sputtering equipment, control sputtering pressure 0.5Pa, sputtering power 300W, sputtering time 40s, sputtering temperature room temperature, in quartz glass Platinum nanoparticles were sputtered on the surf...

Embodiment 3

[0050] A simple and convenient preparation method for a transparent electrode of an ultra-low concentration hydrogen peroxide sensor, comprising the following steps:

[0051] (1) Use methane as the carbon source gas, argon as the carrier gas, and hydrogen as the reducing gas to form a mixed gas, pass it into the chemical vapor deposition equipment, and use the normal pressure (one atmospheric pressure) chemical vapor deposition method at a temperature of 950°C Deposit and grow graphene on the surface of quartz glass for 4h to prepare graphene on quartz glass; the volume ratio of the argon, hydrogen and carbon source gas is 30:5:1, and the flow rate of the mixed gas is 200 sccm.

[0052] (2) Using platinum sheet (purity 99.99wt%) as sputtering target, using vacuum magnetron sputtering equipment, control sputtering pressure 0.7Pa, sputtering power 100W, sputtering time 2min, sputtering temperature room temperature, in quartz glass Platinum nanoparticles were sputtered on the sur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com