Disc type dragging and power generation integrated pulse power supply system

A pulsed power supply, integrated technology, applied in electrical components, electromechanical devices, electric components and other directions, can solve the problems of low energy storage density and power density, low system compactness, high noise, etc., to improve energy storage density, reduce Noise, impact reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

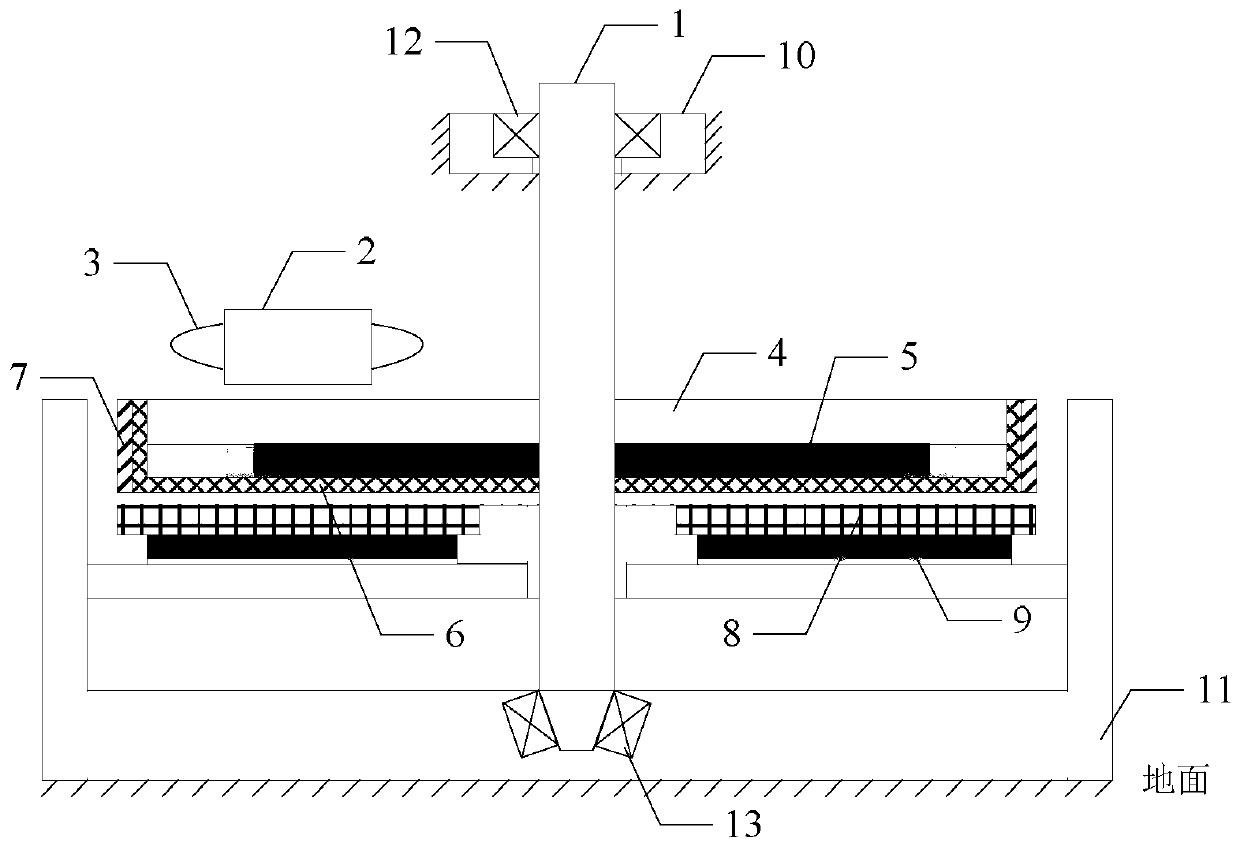

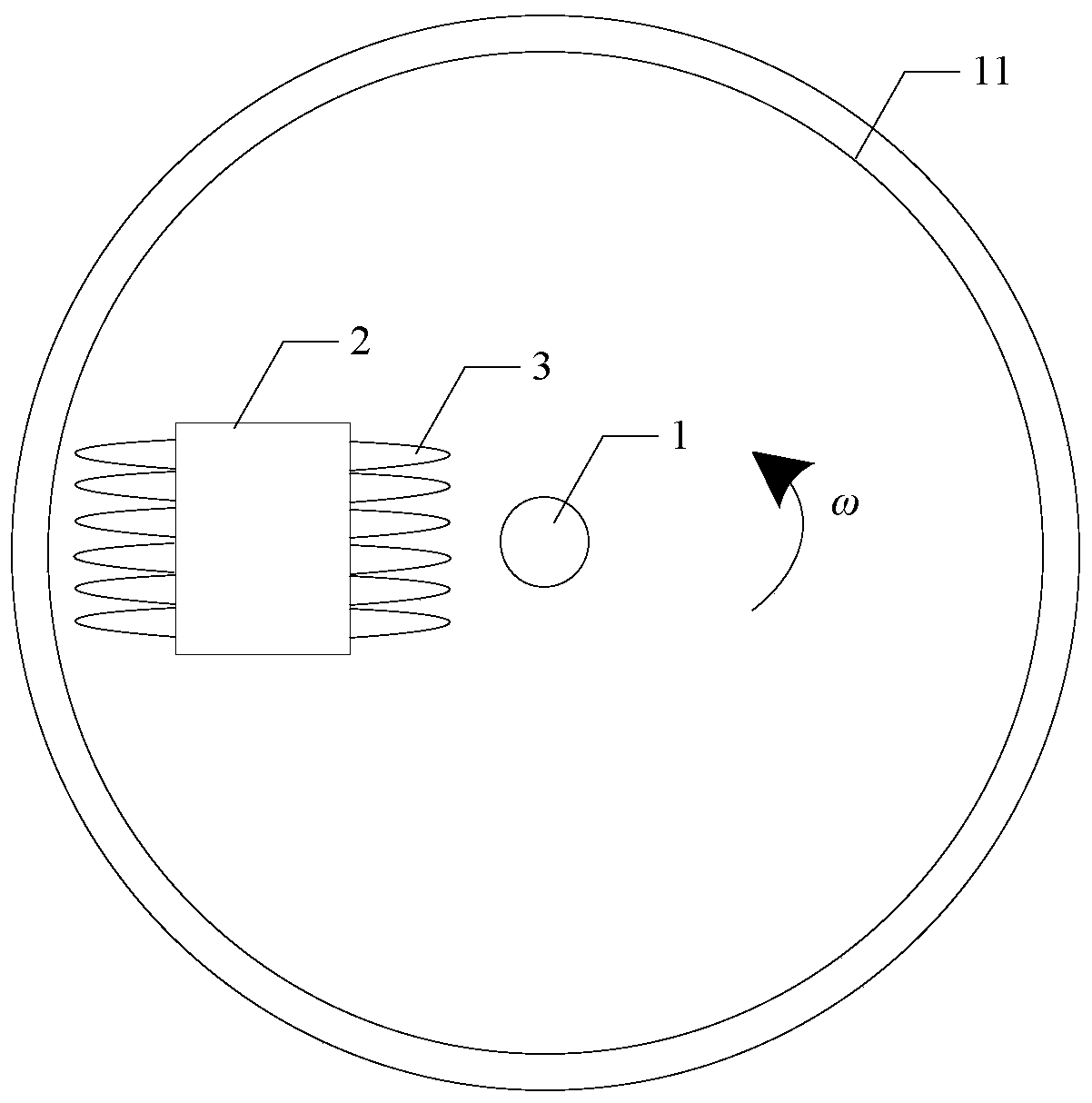

[0024] Specific implementation mode one: combine Figure 1 to Figure 3 Describe this embodiment, a disc drive and power generation integrated pulse power supply system described in this embodiment is characterized in that the integrated pulse power supply system includes an upper stator, a rotor, a lower stator, a fixing device 10, a fixing platform 11. Ball bearing 12 and tapered bearing 13;

[0025] The upper stator includes a No. 1 stator yoke 2 and a motor stator winding 3;

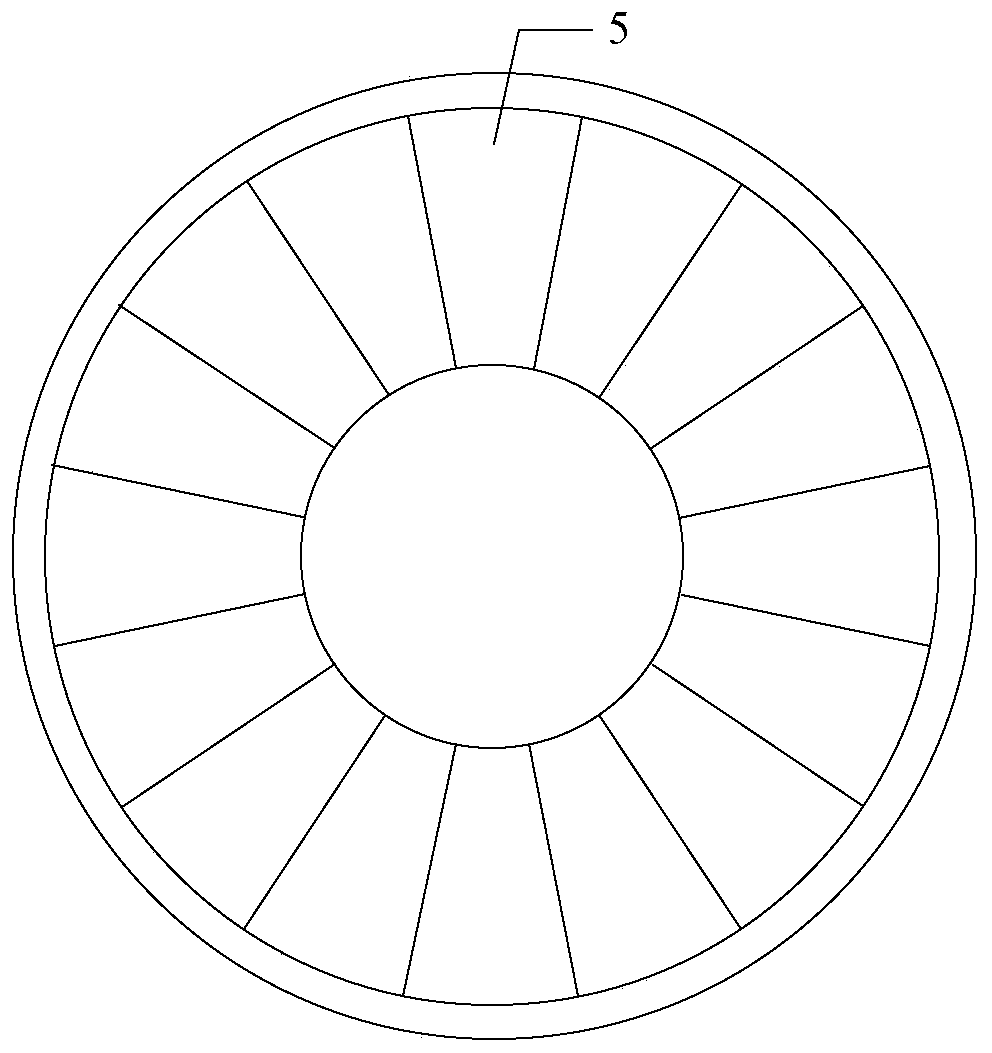

[0026] The rotor includes a rotating shaft 1, an energy storage flywheel 4, a permanent magnet 5, a compensating element 6 and a rotor bandage 7;

[0027] The lower stator includes an armature winding 8 and a second stator yoke 9;

[0028] The outer ring of the tapered bearing 13 is fixed in the fixed platform 11, the outer ring of the ball bearing 12 is fixed in the fixing device 10, and the two ends of the rotating shaft 1 are respectively fixed on the inner ring of the tapered bearing 13 and the ...

specific Embodiment approach 2

[0036] Specific implementation mode two: combination Figure 4 Describe this embodiment, this embodiment is to further limit a kind of disk drive and power generation integrated pulse power supply system described in the first embodiment, in this embodiment, the permanent magnet 5 is a Halbach permanent magnet array structure .

specific Embodiment approach 3

[0037] Specific Embodiment 3: This embodiment is to further limit the disk drive and power generation integrated pulse power supply system described in Embodiment 1 or 2. In this embodiment, the motor stator winding 3 and the permanent magnet 5 The air gap magnetic density generated is axial.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com