Method for making arrow launcher barrel

A technology of a launcher and a cylinder body is applied in the field of the manufacture of a composite material launcher cylinder, which can solve the problems of high manufacturing cost, plastic deformation of metal lining, local combustion, etc., and achieves improved structural integrity, small difference in expansion coefficient, The effect of increasing the interface strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described in detail below in conjunction with the accompanying drawings and preferred embodiments.

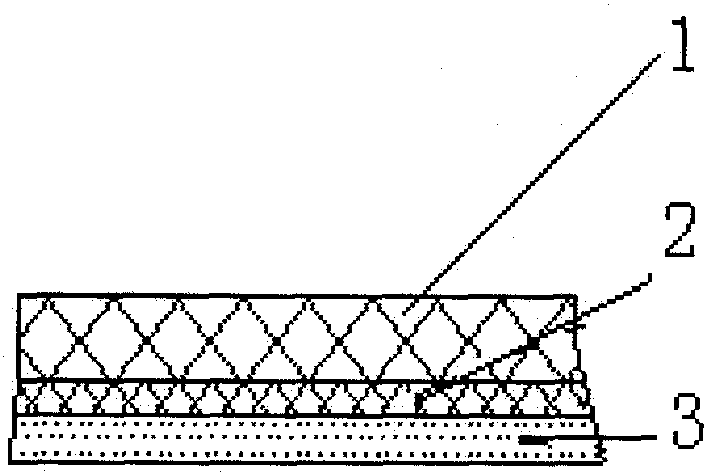

[0015] as figure 1 As shown, the preferred embodiment of the composite material for the barrel of the rocket launcher of the present invention includes a strength structure layer 1 , a transition structure layer 2 , and an ablation-resistant structure layer 3 . The ablation-resistant structural layer 3 is a coating formed by a phenolic resin-based ablation-resistant paint through a spraying process, and this structural layer will serve as the inner wall of the emitter cylinder. The transition structure layer 2 is made of two layers of 0.1 mm glass fiber non-alkali cloth reinforced epoxy resin layer treated by Wolan and bonded on the ablation-resistant structure layer 3 . The strength structure layer 1 is a glass fiber untwisted yarn reinforced epoxy resin layer and is compounded on the transition structure layer 2 .

[0016] A pref...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com