Preparation method of nitric acid oxidation modified high-temperature carbonized activated bamboo charcoal

A technology of activated bamboo charcoal and high-temperature carbonization, which is applied in chemical instruments and methods, and other chemical processes, can solve the problems of small specific surface area and uneven pore size distribution of activated carbon, and achieve fast adsorption speed, uniform pore size distribution, and developed pore structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

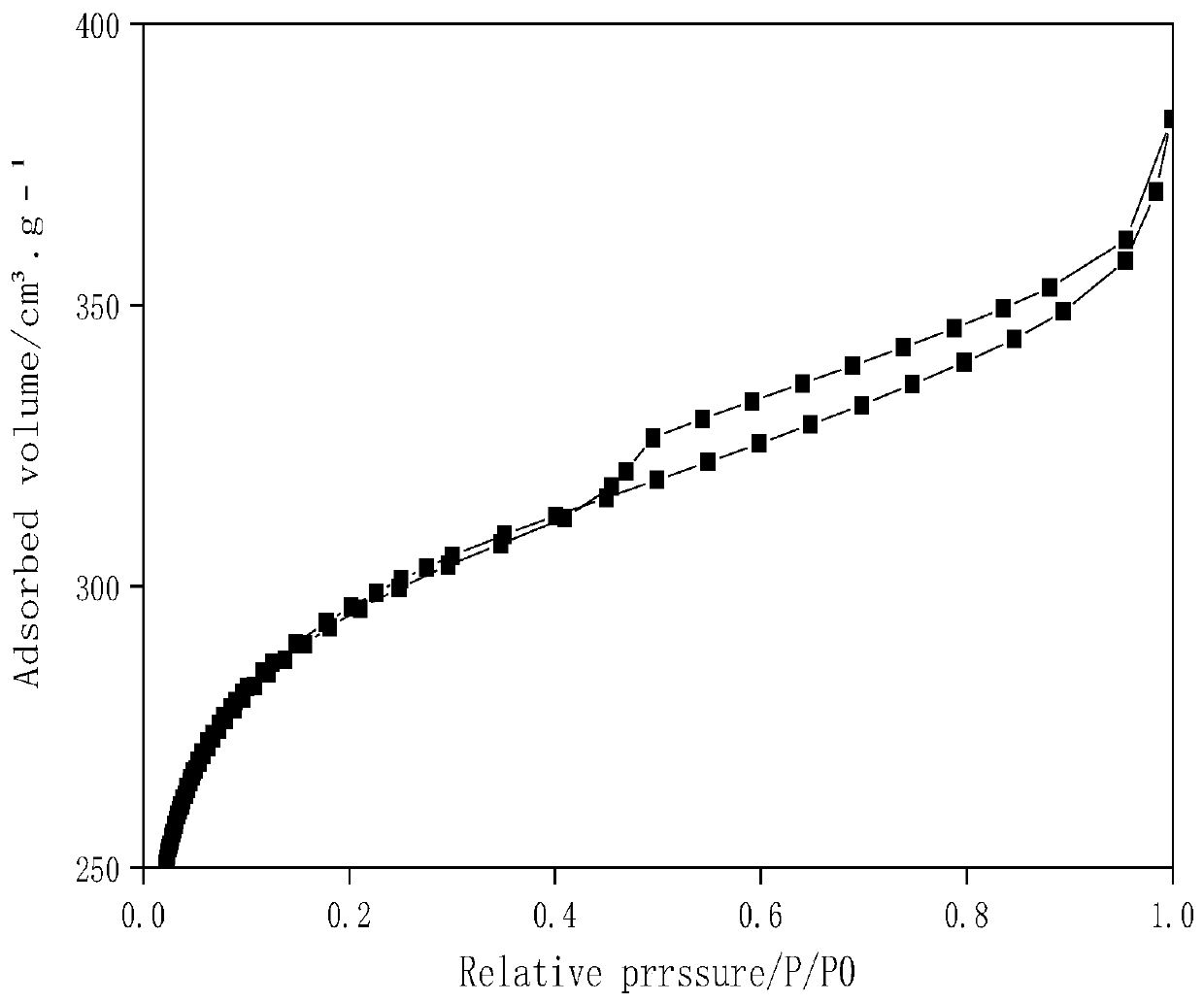

Image

Examples

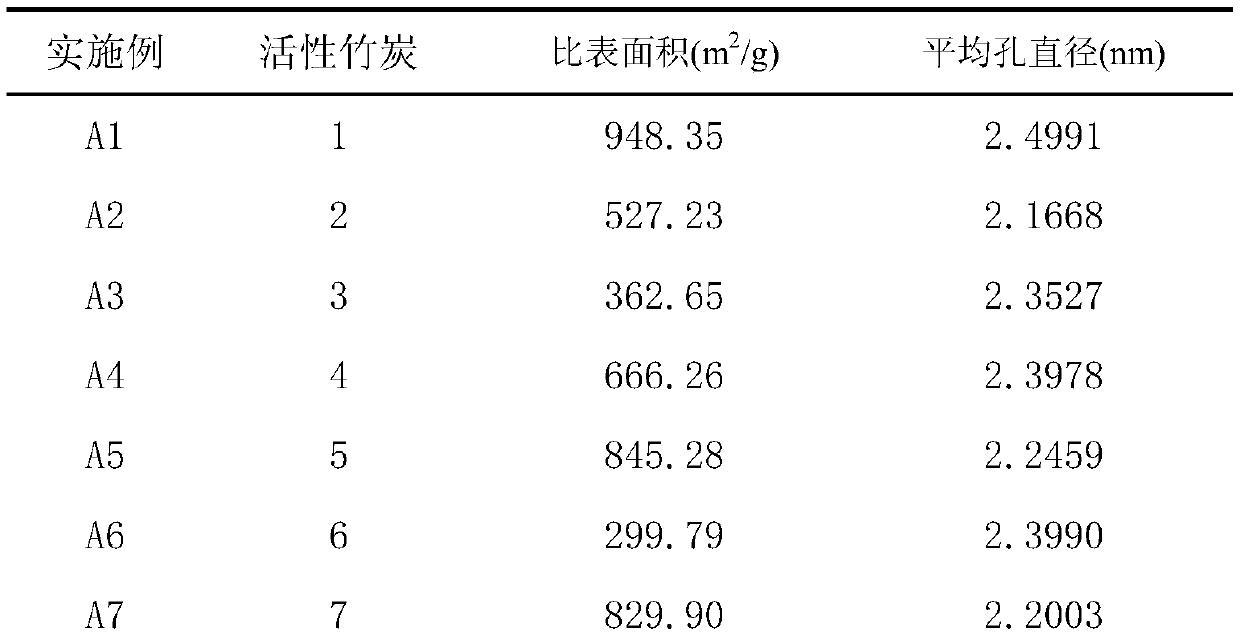

Embodiment 1

[0027] Embodiment 1: A kind of preparation method of nitric acid oxidation modified high-temperature carbonization active bamboo charcoal, specifically: bamboo branch is dried 48h in 120 ℃ of electric heating constant temperature blowing drying ovens, under the condition of flowing nitrogen, through 800 ℃ of carbonization, obtain bamboo material carbonization. The carbonized bamboo material is pulverized and sieved through a 100-mesh sieve to obtain bamboo material powder. Take 5g of bamboo material powder and add 1mol / L HNO3 solution for impregnation, place it in a collector-type constant temperature heating magnetic stirrer at 60°C and stir for 24 hours, then wash the bamboo material powder twice with the distilled water and absolute ethanol washed last time, and then Repeated washing with new distilled water and absolute ethanol to neutrality, vacuum filtration, and drying at 60° C. for 6 hours to obtain a powder product. The powder product was calcined at 1000°C under nit...

Embodiment 2

[0028] Embodiment 2: A kind of preparation method of nitric acid oxidation modified high-temperature carbonized active bamboo charcoal, specifically: bamboo branch is dried 48h in 120 ℃ of electric heating constant temperature air blast drying box, under the condition of flowing nitrogen, through 800 ℃ of carbonization, obtain bamboo material carbonization. The carbonized bamboo material is pulverized and sieved through a 100-mesh sieve to obtain bamboo material powder. Take 5g of bamboo material powder and add 1mol / L HNO3 solution for impregnation, place it in a collector-type constant temperature heating magnetic stirrer at 60°C and stir for 24 hours, then wash the bamboo material powder twice with the distilled water and absolute ethanol washed last time, and then Repeated washing with new distilled water and absolute ethanol to neutrality, vacuum filtration, and drying at 60° C. for 6 hours to obtain a powder product. The powder product was calcined at 800°C for 4 hours u...

Embodiment 3

[0029] Embodiment 3: A kind of preparation method of nitric acid oxidation modified high-temperature carbonized active bamboo charcoal, specifically: bamboo branch is dried 48h in 120 ℃ electric heating constant temperature blower drying box, under the condition of flowing nitrogen, through 800 ℃ carbonization, obtain bamboo material carbonization. The carbonized bamboo material is pulverized and sieved through a 100-mesh sieve to obtain bamboo material powder. Take 5g of bamboo material powder and add 1mol / L HNO3 solution for impregnation, place it in a collector-type constant temperature heating magnetic stirrer at 60°C and stir for 24 hours, then wash the bamboo material powder twice with the distilled water and absolute ethanol washed last time, and then Repeated washing with new distilled water and absolute ethanol to neutrality, vacuum filtration, and drying at 60° C. for 6 hours to obtain a powder product. The powder product was calcined at 600°C under nitrogen atmosph...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com