Bulk phase catalyst capable of doing not generate waste liquid, and preparation method thereof and hydrogenation catalyst containing bulk phase catalyst

A bulk catalyst and waste liquid technology, applied in chemical instruments and methods, physical/chemical process catalysts, hydrocarbon oil treatment products, etc., can solve problems such as low catalytic activity and environmental pollution, to avoid pollution and save cumbersome treatment The effect of steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035] The invention provides a method for preparing a bulk catalyst that does not generate waste liquid. The bulk catalyst that does not generate waste liquid is used for hydrogenation reactions of petroleum products. The preparation method includes the following steps:

[0036] Step 1, dissolving the compound containing group VIB elements in a solvent to prepare a solution, and adjusting the pH value of the solution to 6-11;

[0037] Step 2, mixing the solution obtained in step 1 with a powder compound containing Group VIII elements, and stirring evenly to obtain a mixture;

[0038] Step 3, placing the mixture obtained in step 2 in an airtight container for reaction, the reaction time is at least 10 minutes, and the reaction temperature is 5-75°C; and

[0039] Step 4, heating the mixture to 80-200°C for reaction, the reaction time is at least 1 hour, and drying to obtain a bulk catalyst;

[0040] Wherein, the volume of the solvent is 1 to 2 times the saturated water absorpt...

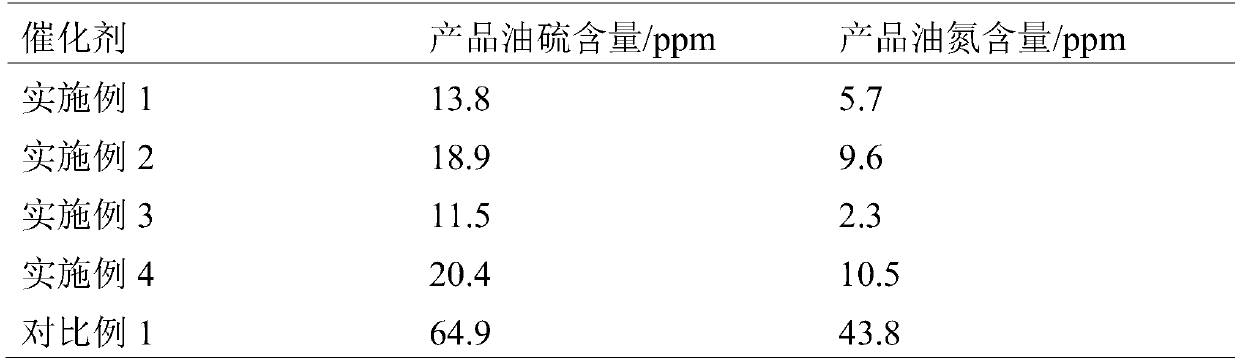

Embodiment 1

[0055] Weigh 8.83g of ammonium heptamolybdate and 13.48g of ammonium metatungstate, and add them into 10g of water to prepare a solution. In the solution, ammonia water with a mass concentration of 25% was added dropwise until the pH value of the solution was 9, then mixed with 12.54 g of basic nickel carbonate, and stirred evenly. The system was placed in a closed reactor, reacted at 35°C for 2 hours, then heated to 150°C, reacted for 2 hours, then cooled, and the obtained wet solid was dried at 120°C for 4 hours. A bulk catalyst is obtained.

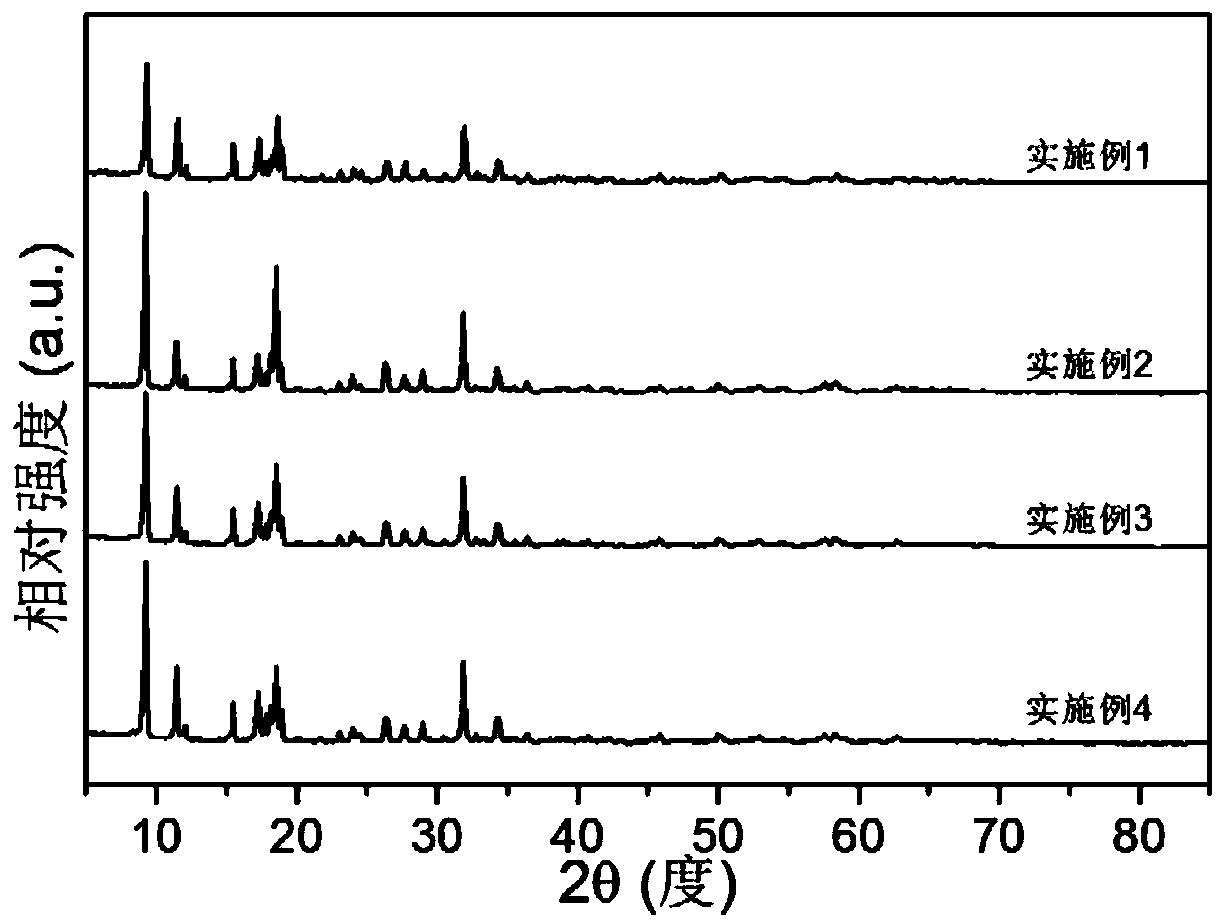

[0056] In this embodiment, during the reaction process of the system at 35°C, bulk catalyst seeds are gradually generated, and the specific reaction mechanism is: the low-temperature reaction conditions provided by the present invention promote the generation of heptamolybdate ions and Ni ions present in the solution. rearrangement, so that a large number of generated (NH 4 ) 4 h 6 NiMo 6 o 24 ·5H 2 O, carry out XRD test to the ...

Embodiment 2

[0058] Weigh 4.41g of ammonium heptamolybdate and 26.96g of ammonium metatungstate, and add them into 20g of water to prepare a solution. In the solution, add 4.01g of urea, the pH value of the solution is 8, then mix the solution with the mixed powder of 12.03g of basic nickel carbonate and 0.57g of basic cobalt carbonate, and stir evenly. The system was placed in a closed reactor, reacted at 45°C for 3 hours, then heated up to 120°C, reacted for 3 hours, then cooled, and the obtained wet solid was dried at 120°C for 4 hours. A bulk catalyst is obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com