Preparation method and application of catalyst for synthesizing methyl methacrylate

A technology of methyl methacrylate and catalyst, which is applied in the direction of molecular sieve catalyst, aldehyde redox preparation, chemical instruments and methods, etc., can solve the problems of high conversion rate and selectivity, expensive catalyst, reduced catalyst activity, etc., to achieve improved Stability, good wear resistance, effect of reducing wear rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

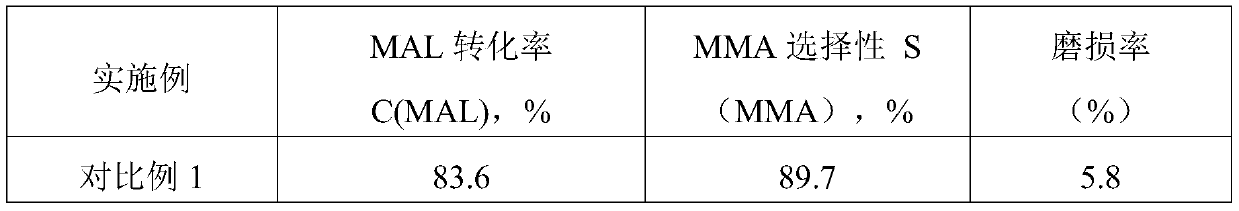

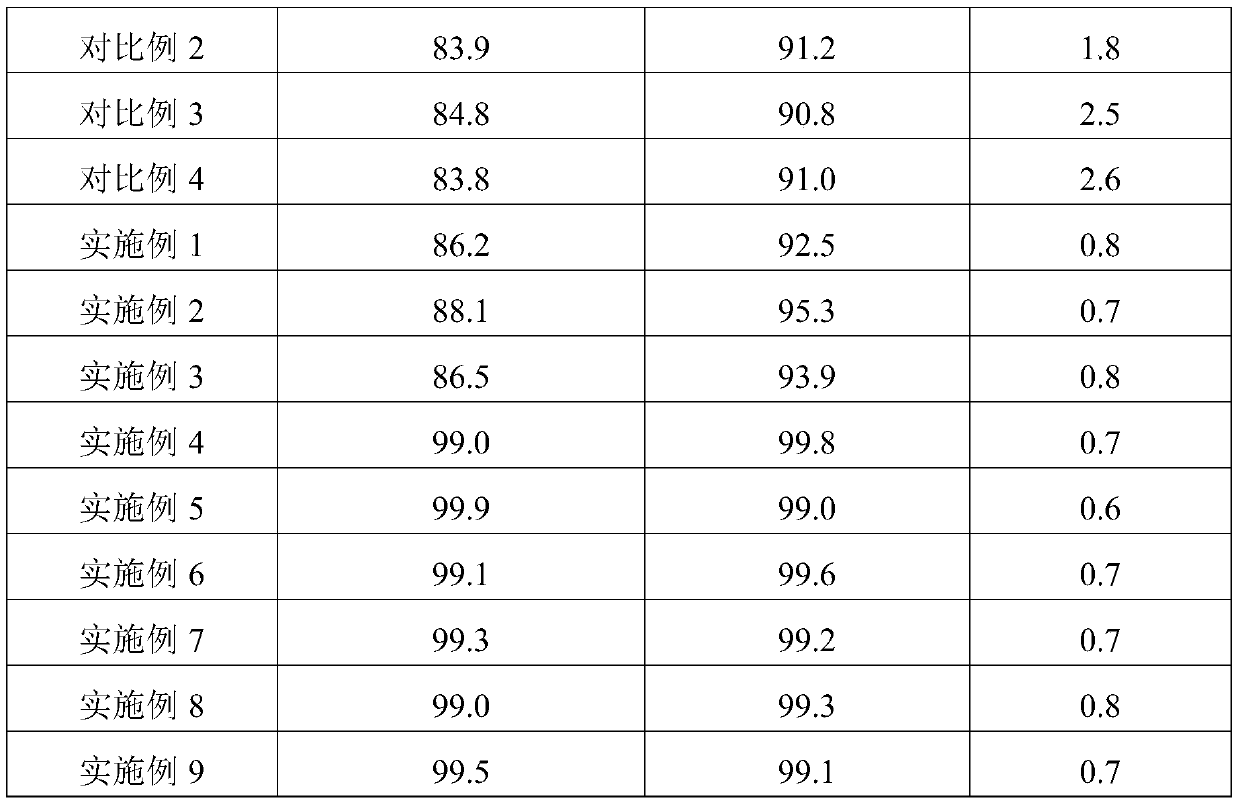

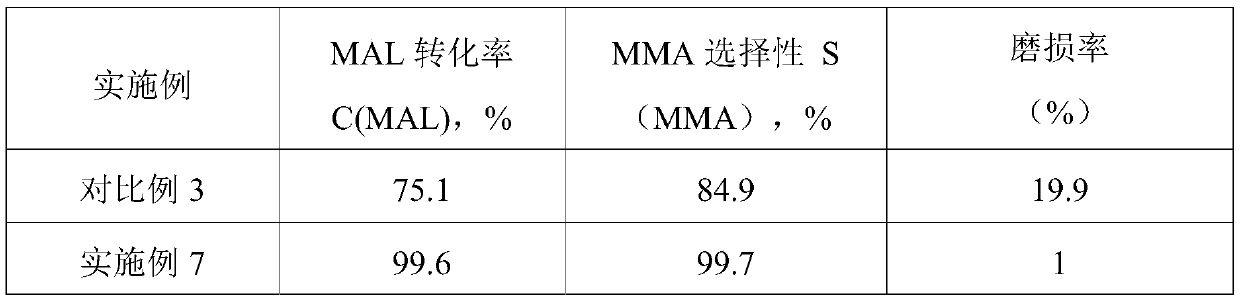

Examples

Embodiment 1

[0056] The preparation method of the catalyst of synthesizing methyl methacrylate comprises 1) the preparation of carrier: 25kg water and 27.7kg sodium silicate aqueous solution and 660gNaOH are mixed and added in 13.9kg to be dissolved in 1.26kg octadecadecane aluminum sulfate aqueous solution, Stir rapidly, then add 2.6kg of n-butylamine and mix evenly, put it in a crystallization kettle, crystallize at 170°C for 2 days, and then reduce the temperature under reduced pressure to recover the template agent n-butylamine to obtain a crystallization mother liquor containing ZSM-5 molecular sieve; The obtained crystallization mother liquor is adjusted to PH value to 2 with nitric acid and stirred evenly, then the evenly stirred mixture is spray-dried at 150°C, the spraying conditions are: 10ml / min feed rate, inlet temperature 200-220°C, outlet temperature 80 -100°C, then calcined at 550°C for 6h to obtain sodium ZSM-5 molecular sieve carrier SiO 2 / Al 2 o 3 The molar ratio was 8...

Embodiment 2

[0059] The preparation method of the catalyzer of synthesizing methyl methacrylate comprises the following steps: 25kg water and 27.7kg sodium silicate aqueous solution and 660gNaOH are mixed and added in the 1.6kg octadecadecane aluminum sulfate aqueous solution with 13.9kg water-dissolving, fast stirring, Then add 2.6kg of n-butylamine and mix evenly, put it in a crystallization kettle, crystallize at 170°C for 2 days, then reduce the temperature under reduced pressure to recover the template agent n-butylamine, and obtain a crystallization mother liquor containing ZSM-5 molecular sieve; Use nitric acid to adjust the pH value of the mother liquor to 2 and stir evenly, then spray dry the stirred mixture at 150°C, the spraying conditions are: 10ml / min feed rate, inlet temperature 200-220°C, outlet temperature 80-100°C , and then calcined at 550°C for 6h to obtain the sodium ZSM-5 molecular sieve carrier SiO 2 / Al 2 o 3 The molar ratio was 65.

[0060] The preparation proces...

Embodiment 3

[0062] The preparation method of the catalyzer of synthesizing methyl methacrylate comprises the following steps: 25kg water and 27.7kg sodium silicate aqueous solution and 660gNaOH are mixed and added in 13.9kg water-dissolved 0.6kg aluminum sulfate eighteen water aqueous solution, stirring rapidly, Then add 2.6kg of n-butylamine and mix evenly, put it in a crystallization kettle, crystallize at 170°C for 2 days, then reduce the temperature under reduced pressure to recover the template agent n-butylamine, and obtain a crystallization mother liquor containing ZSM-5 molecular sieve; Use nitric acid to adjust the pH value of the mother liquor to 2 and stir evenly, then spray dry the stirred mixture at 150°C, the spraying conditions are: 10ml / min feed rate, inlet temperature 200-220°C, outlet temperature 80-100°C , and then calcined at 550°C for 6h to obtain the sodium ZSM-5 molecular sieve carrier SiO 2 / Al 2 o 3 The molar ratio was 160.

[0063] The preparation process of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com