Biomass granular fuel crushing device with material pressing function

A biomass particle and crushing device technology, which is applied in the direction of biofuel, waste fuel, fuel, etc., can solve the problems of hindering fine particle materials from passing through the screen, increasing rotor resistance, insufficient and other problems, so as to improve the screening efficiency and improve the Pulverization efficiency, sufficient pulverization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

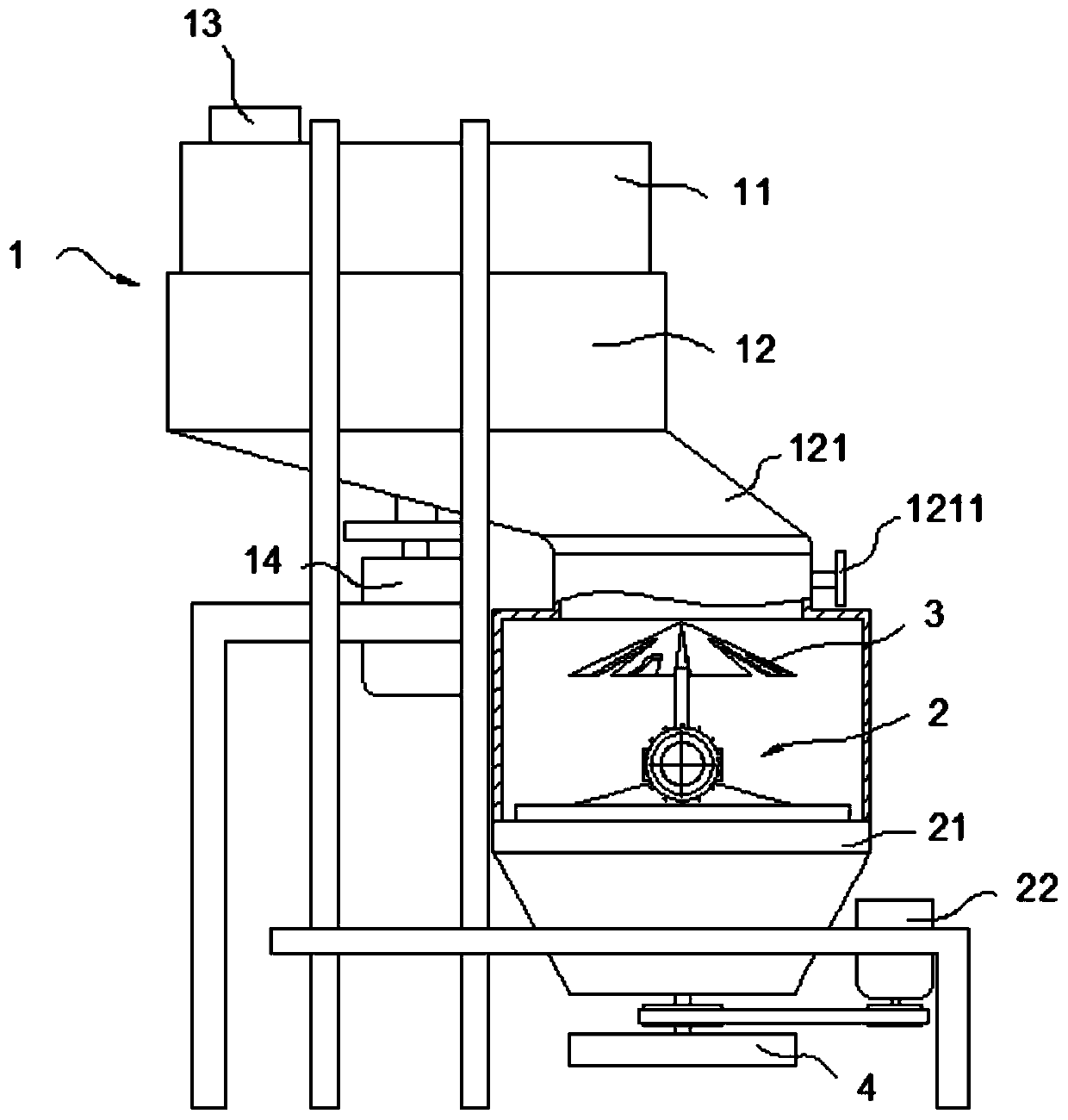

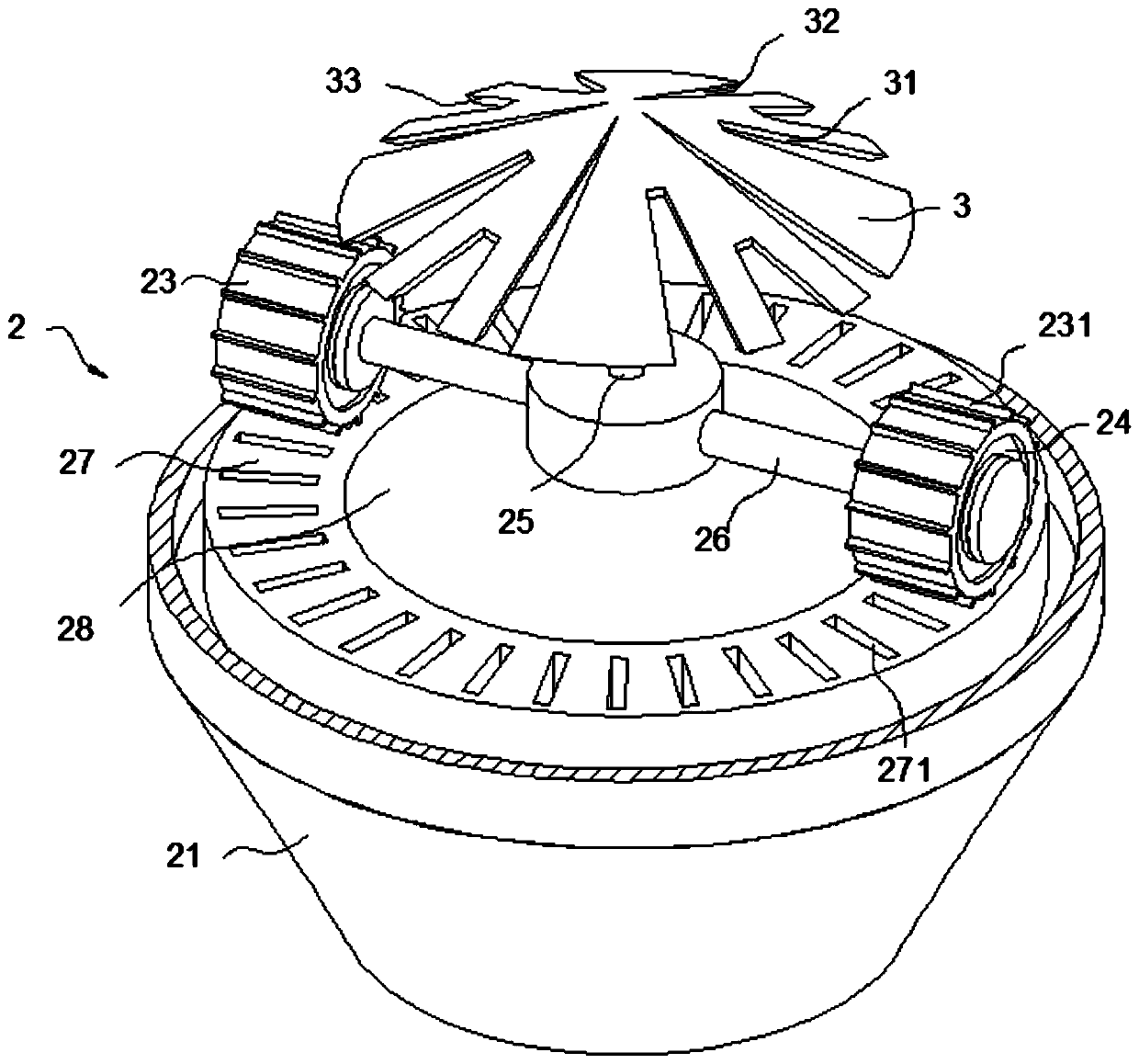

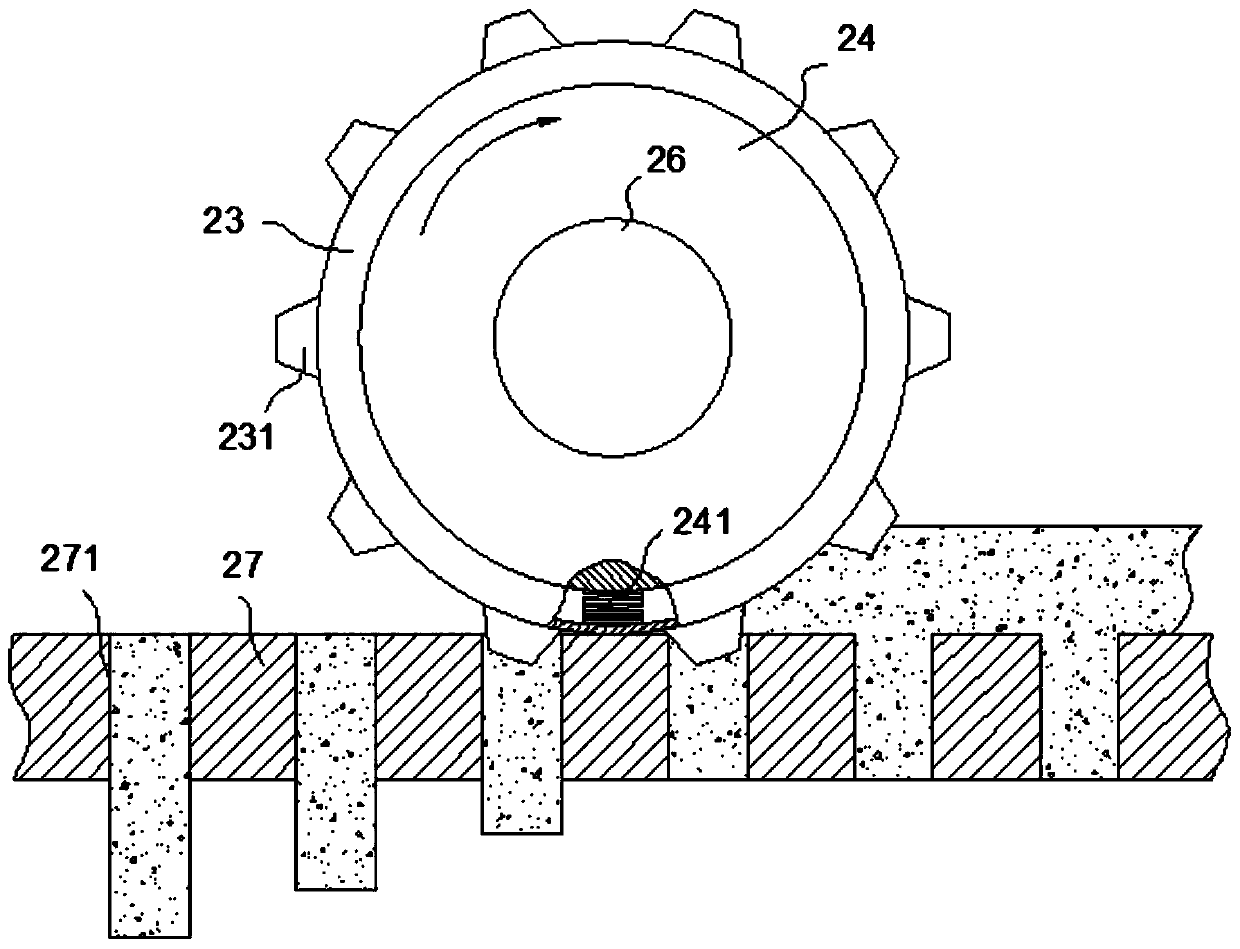

[0037] Embodiment: When using the crushing device, the rod-shaped material to be crushed is first cut into short sections by the chopping knife of the crushing device 1, and then crushed into powder by the L-shaped blade 181, and the crushed material is stored in the storage In the material bin 121, the material is put into the material distribution plate 3 and rotated to distribute the material under the control of the material blocking valve 1211, and then rolled into small pieces by the flat die rolling device 2, and then put into the discharge hopper 4.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com