Technology for processing wastewater generated in lincomycin antibiotic production

A technology for the production of wastewater and lincomycin, which is applied in water/sewage treatment, natural water treatment, oxidized water/sewage treatment, etc., can solve the problems of high SS concentration, high salt concentration, high COD concentration, etc., and achieve improved dehydration performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

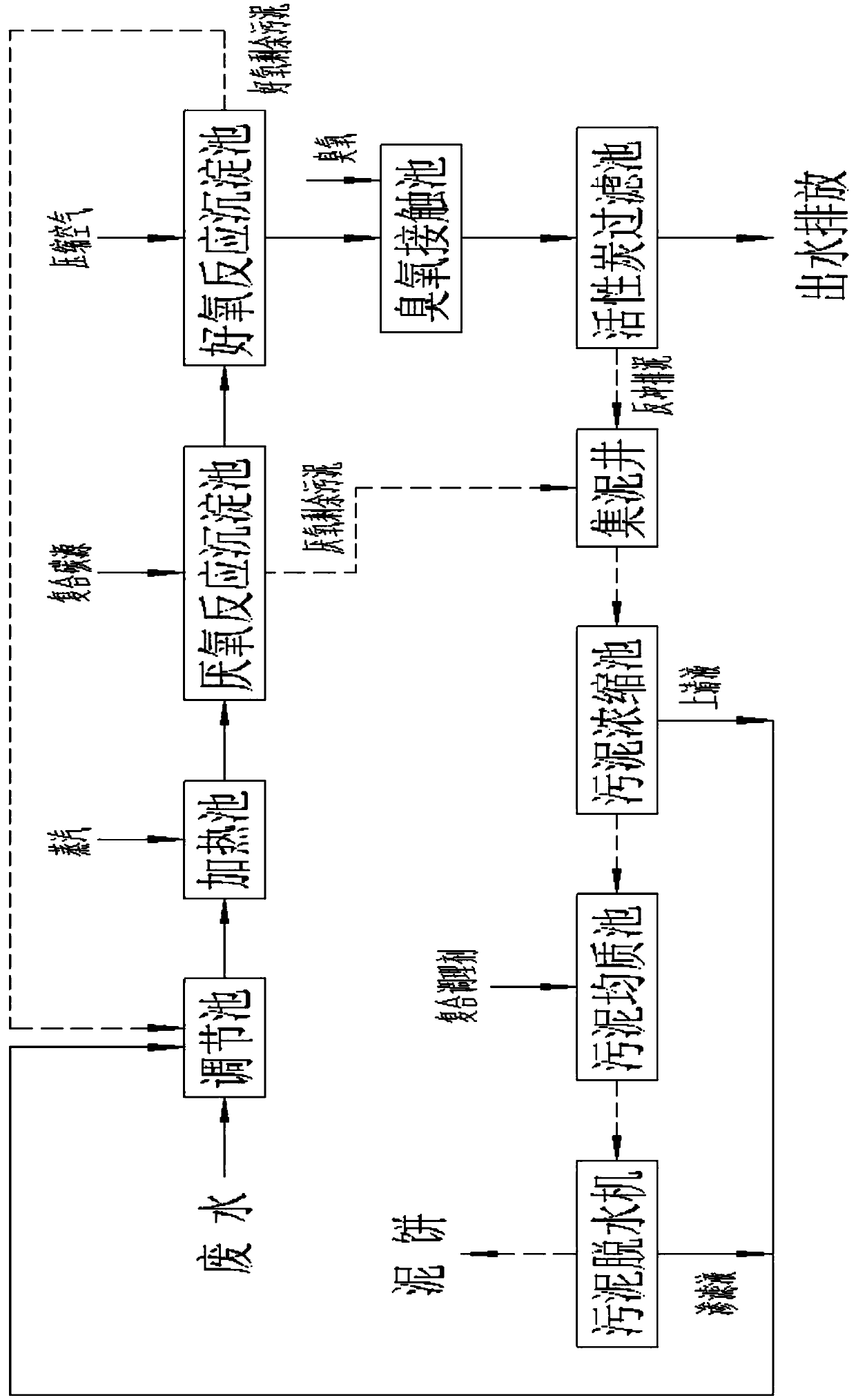

[0030] like figure 1 Shown, the present invention handles lincomycin class antibiotic production waste water, and main procedure has:

[0031] 1) The lincomycin-type antibiotic production wastewater discharged from the production workshop flows into the regulating pool by itself. The regulating pool plays the role of equalizing the water quality and regulating the water volume. The hydraulic retention time is 4.0-6.0h, and the effluent is pumped to the heating pool by the sewage lifting pump installed at the bottom of the pool.

[0032] 2) Wastewater enters the heating pool. Heating is carried out by the steam passing into the heating pool, the heated water temperature is controlled at 34-36°C, and the hydraulic retention time of the heating pool is 15 minutes.

[0033] 3) The effluent from the heating pool flows into the anaerobic reaction sedimentation tank by gravity. The hydraulic retention time of the anaerobic reaction sedimentation tank is 27.0h.

[0034] The compos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com