Anti-cracking inorganic waterproof material and preparation method thereof

A waterproof material and anti-crack technology, applied in the field of building materials, can solve the problems of poor compressive strength and waterproof effect, unguaranteed crystal strength, limited waterproof effect, etc. handy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

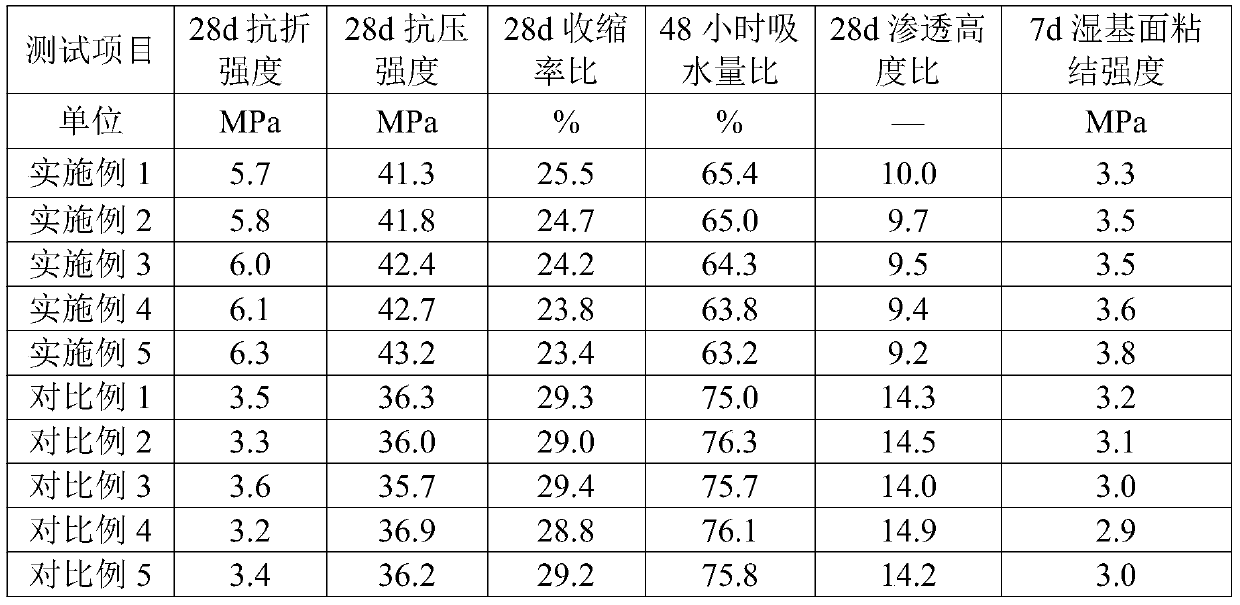

Examples

Embodiment 1

[0031] An anti-cracking inorganic waterproof material is characterized in that it comprises the following components in parts by weight: 50 parts of cement, 10 parts of pyrophyllite powder, 20 parts of saponite powder, 10 parts of silicon coal, 2-chloroethoxyethanol Ionized tris(dimethylamino)chlorosilane 0.5 part, tetrakis(2-trichlorosilylethyl)silane 0.1 part, pectic acid 0.1 part, surface modified Be-Mn-Ca-O 1 part, aluminum silicate 0.3 part of sodium, 1 part of hyperbranched polychitosan, 1 part of black phosphorus, 2 parts of blast furnace slag, 0.5 part of vermiculite, 1 part of SM superplasticizer; the cement is fluoroaluminate cement, pozzolanic portland cement Mixed according to the mass ratio of 1:3.

[0032] The preparation method of the 2-chloroethoxyethanol ionized tris(dimethylamino)chlorosilane comprises the following steps: adding 191g of 2-chloroethoxyethanol and 100g of tris(dimethylamino)chlorosilane to 1000g of acetone , stirred and reacted at 40°C for 4 ...

Embodiment 2

[0039] A crack-resistant inorganic waterproof material is characterized in that it comprises the following components in parts by weight: 52 parts of cement, 11 parts of pyrophyllite powder, 22 parts of saponite powder, 11 parts of silicon coal, 2-chloroethoxyethanol 0.7 parts of ionized tris(dimethylamino)chlorosilane, 0.15 parts of tetrakis(2-trichlorosilylethyl)silane, 0.15 parts of pectic acid, 1.5 parts of surface modified Be-Mn-Ca-O, silicon 0.4 parts of sodium aluminum acid, 1.2 parts of hyperbranched polychitosan, 1.2 parts of black phosphorus, 3 parts of blast furnace slag, 0.7 parts of alumite, 1.2 parts of UNF water reducer; the cement is fluoroaluminate cement, pozzolanic silicic acid Salt cement is mixed at a mass ratio of 1:3.5.

[0040] The preparation method of the 2-chloroethoxyethanol ionized tris(dimethylamino)chlorosilane comprises the following steps: adding 191g of 2-chloroethoxyethanol and 100g of tris(dimethylamino)chlorosilane to dichloro In 1150g of ...

Embodiment 3

[0047] An anti-cracking inorganic waterproof material is characterized in that it comprises the following components in parts by weight: 55 parts of cement, 13 parts of pyrophyllite powder, 23 parts of saponite powder, 13 parts of silicon coal, 2-chloroethoxyethanol 1 part of ionized tris(dimethylamino)chlorosilane, 0.2 part of tetrakis(2-trichlorosilylethyl)silane, 0.2 part of pectic acid, 2 parts of surface modified Be-Mn-Ca-O, silicic acid 0.5 parts of sodium aluminum, 1.5 parts of hyperbranched polychitosan, 1.5 parts of black phosphorus, 3.5 parts of blast furnace slag, 1 part of quicklime, and 1.5 parts of SM water reducing agent; the cement is fluoroaluminate cement and pozzolanic portland cement Mixed according to the mass ratio of 1:4.

[0048] The preparation method of the 2-chloroethoxyethanol ionized tris(dimethylamino)chlorosilane comprises the following steps: adding 191g of 2-chloroethoxyethanol and 100g of tris(dimethylamino)chlorosilane to 1300g of diethyl eth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com