Double-phase stainless steel metallographical corrosive liquid formula and application method thereof

A duplex stainless steel and metallographic corrosion technology, which is applied in the preparation of test samples, etc., can solve the problems of combustion and explosion, complicated operation, and high risk of potassium sulfite, so as to improve the overpotential, improve the operating conditions, and the operating conditions are good Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

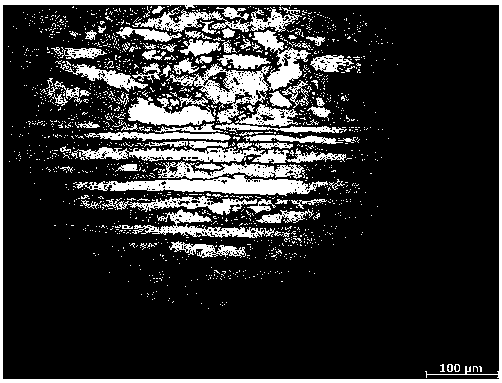

[0033] Taking the calculation of the two-phase ratio of 2205 duplex stainless steel as an example, the specific implementation method is as follows:

[0034] A. Grind the sample to be corroded step by step with 120-2000# sandpaper, and use 3.5 μm and 1 μm Diamond abrasive paste polishing;

[0035] B, 20g of sodium sulfite and 2g of thiourea were dissolved in 45ml of water, and the aqueous solution, 40ml of phosphoric acid, and 52ml of sulfuric acid were added to 160ml of glycerin successively;

[0036] C. Put the metallographic corrosion solution prepared in step B into the container with the cathode installed, and heat it to 42°C in a water bath;

[0037] D. Measure the area of the sample to be corroded, connect the sample to be corroded to the anode of the DC power supply, and press 0.13A / cm 2 Set current size;

[0038] E. Immerse the sample to be corroded in metallographic corrosion solution, turn on the DC power supply, and corrode the sample for 2 minutes;

[003...

Embodiment 2

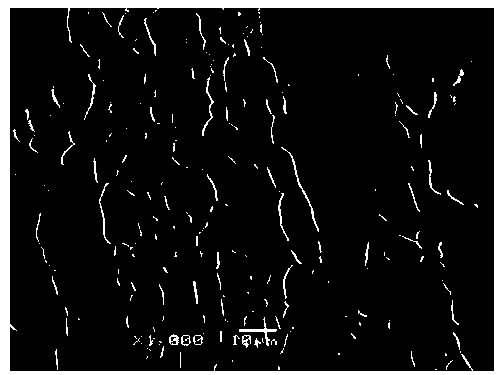

[0042] Taking the use of EDS to measure the two-phase composition of 2507 duplex stainless steel as an example, the specific implementation method is as follows:

[0043] A. Grind the sample to be corroded step by step with 120-2000# sandpaper, and use 3.5 μm and 1 μm Diamond abrasive paste polishing;

[0044] B, 20g of sodium sulfite and 2g of thiourea were dissolved in 45ml of water, and the aqueous solution, 42ml of phosphoric acid, and 54ml of sulfuric acid were added successively in 160ml of glycerol;

[0045] C. Put the metallographic corrosion solution prepared in step B into the container with the cathode installed, and heat it to 45°C in a water bath;

[0046] D. Measure the area of the sample to be corroded, connect the sample to be corroded to the anode of the DC power supply, and press 0.15A / cm 2 Set current size;

[0047] E. Immerse the sample to be corroded in metallographic corrosion solution, turn on the DC power supply, and corrode the sample for 2 min...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com