Magnesium and lithium alloy surface compound oxidation treatment method

A technology of magnesium-lithium alloy and treatment method, which is applied in the direction of anodic oxidation, surface reaction electrolytic coating, electrolytic coating, etc., can solve the problems that cannot meet the requirements of electrical conductivity and corrosion resistance at the same time, and achieve good electromagnetic shielding effect and good electrical conductivity of the workpiece , The effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

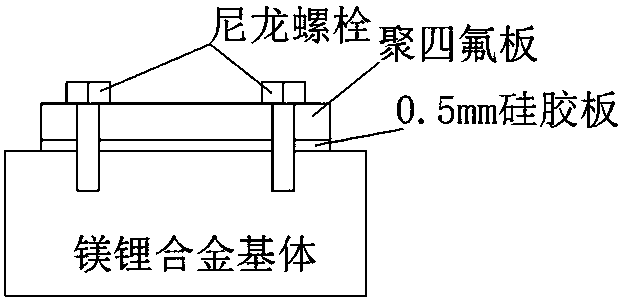

Method used

Image

Examples

Embodiment 1

[0027] A composite oxidation treatment method for the surface of a magnesium-lithium alloy, specifically comprising the following steps, the model of the magnesium-lithium alloy used in this embodiment is LAZ931:

[0028] (1) Cleaning and pretreatment of the surface of the magnesium-lithium alloy substrate: use metallographic sandpaper of models 800#, 1000#, 2000#, and 5000# to polish the surface of the magnesium-lithium alloy to the mirror surface, then polish it with a cloth wheel, and use detergent to polish it. The surface of the finished workpiece is degreased, and finally ultrasonically cleaned with distilled water to remove the oil and oxide film on the surface of the magnesium-lithium alloy;

[0029] (2) Conductive oxidation treatment: place the surface-cleaned magnesium-lithium alloy substrate in a conductive oxidation solution for conductive oxidation treatment. After treatment, rinse the magnesium-lithium alloy parts with deionized water and dry them; The concentrat...

Embodiment 2

[0034] A method for composite oxidation treatment of the surface of a magnesium-lithium alloy, specifically comprising the following steps, the model of the magnesium-lithium alloy used in this embodiment is LA141:

[0035] (1) Cleaning and pretreatment of the surface of the magnesium-lithium alloy substrate: use metallographic sandpaper of models 800#, 1000#, 2000#, and 5000# to polish the surface of the magnesium-lithium alloy to the mirror surface, then polish it with a cloth wheel, remove oil, and finally Ultrasonic cleaning with distilled water to remove oil and oxide film on the surface of the magnesium-lithium alloy;

[0036](2) Conductive oxidation treatment: place the surface-cleaned magnesium-lithium alloy substrate in a conductive oxidation solution for conductive oxidation treatment. After treatment, rinse the magnesium-lithium alloy parts with deionized water and dry them; The concentration of each component is K 2 CrO 7 30g / L, (NH 4 ) 2 SO 4 3g / L, NaF 3g / L...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com