Surface modified fibre for filling reinforcement, preparation method of surface modified fibre for filling reinforcement, and fibre reinforced composite material

A technology of surface modification and composite materials, which is applied in the fields of carbon fiber, fiber treatment, textiles and papermaking, etc., which can solve problems such as low shear strength, poor composite effect of fiber and matrix, and damage to the mechanical properties of fiber precursors. Mechanical properties, improvement of fiber surface properties, and enhancement of interfacial bonding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] The surface-modified fiber for filling and reinforcement in this embodiment consists of a fiber body and a hybrid coating loaded on the surface of the fiber body. The hybrid coating consists of a polyvinyl alcohol matrix and graphene oxide dispersed in the polyvinyl alcohol matrix Composition, the mass ratio of polyvinyl alcohol and graphene oxide in the hybrid coating is 5:0.1, and the sheet thickness of graphene oxide is 3-8nm. The fiber body is carbon fiber and glass fiber with a volume ratio of 1:1. In other implementations, a single fiber may be used, such as carbon fiber or glass fiber.

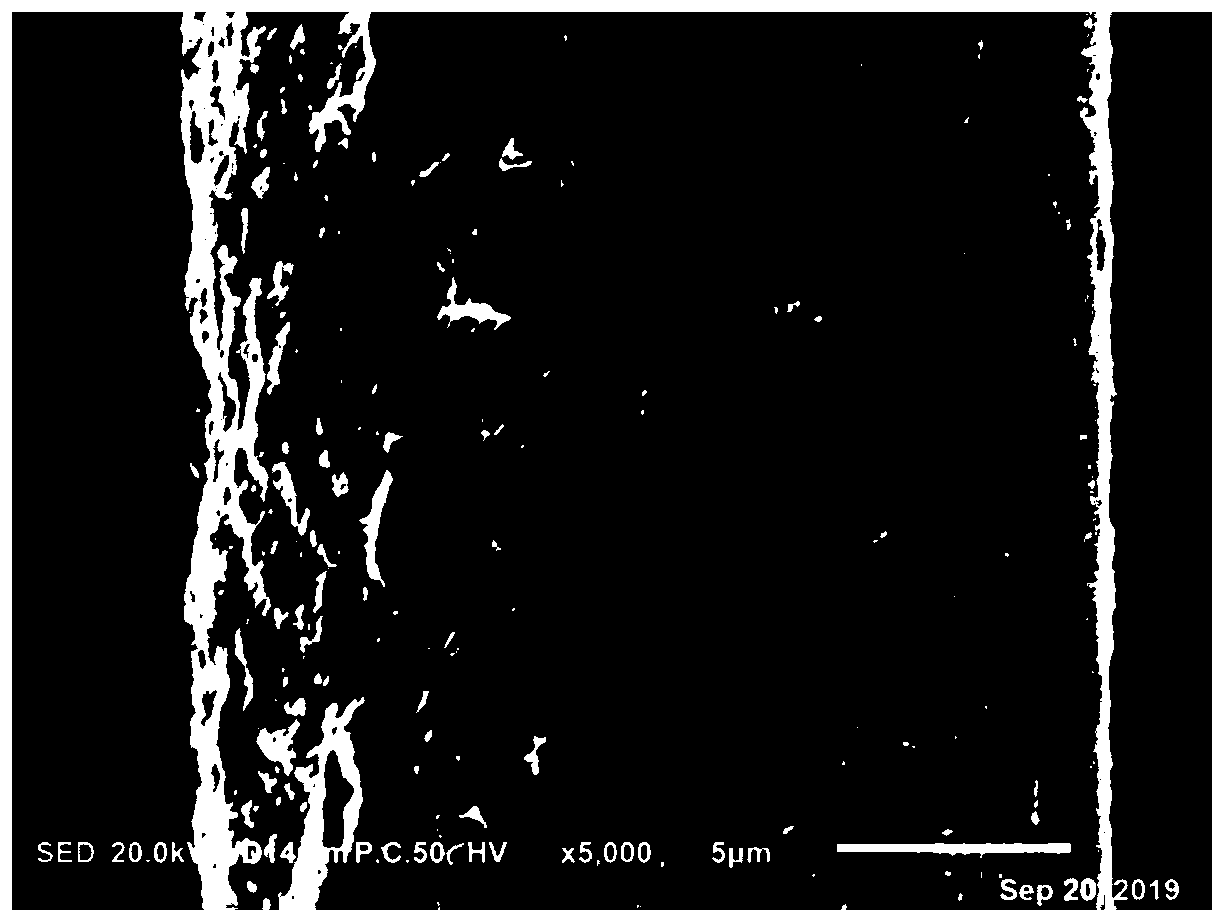

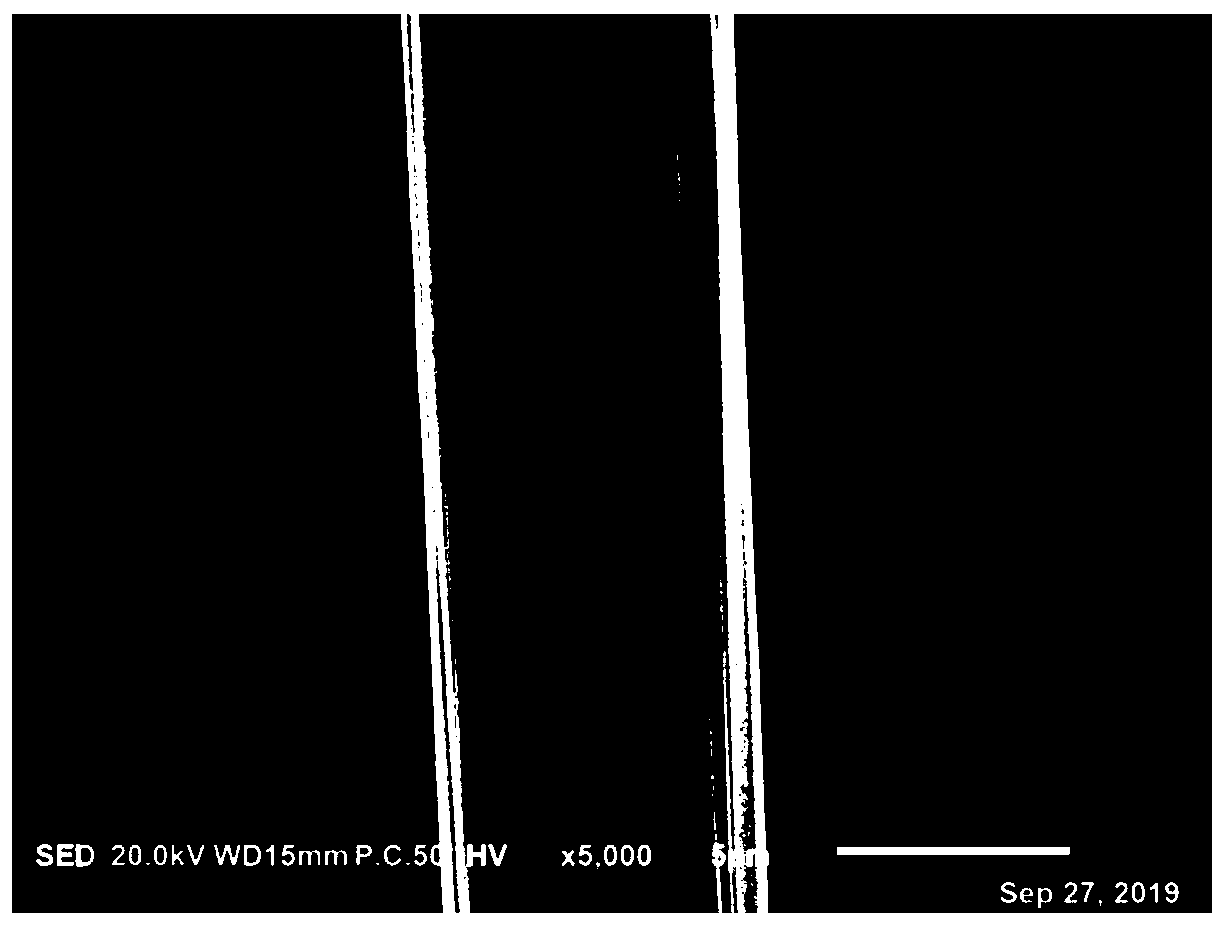

[0035] The scanning electron microscope images of the glass fiber surface before and after surface modification are as follows: figure 1 with figure 2 As shown, the scanning electron microscope images of the carbon fiber surface before and after surface modification are as follows image 3 with Figure 4 As shown, the comparison shows that the surface of glass fiber and carb...

Embodiment 2

[0037] The surface-modified fiber for filling and reinforcement in this embodiment consists of a fiber body and a hybrid coating loaded on the surface of the fiber body. The hybrid coating consists of a polyvinyl alcohol matrix and graphene oxide dispersed in the polyvinyl alcohol matrix Composition, the mass ratio of polyvinyl alcohol and graphene oxide in the hybrid coating is 0.5:5, and the sheet thickness of graphene oxide is 3-8nm. The fiber body is carbon fiber and glass fiber with a volume ratio of 1:1.

Embodiment 3

[0039]The surface-modified fiber for filling and reinforcement in this embodiment consists of a fiber body and a hybrid coating loaded on the surface of the fiber body. The hybrid coating consists of a polyvinyl alcohol matrix and graphene oxide dispersed in the polyvinyl alcohol matrix Composition, the mass ratio of polyvinyl alcohol and graphene oxide in the hybrid coating is 2:3, and the sheet thickness of graphene oxide is 3-8nm. The fiber body is carbon fiber and glass fiber with a volume ratio of 1:1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Sheet thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com