Grouting type steel tube screw pile and construction method thereof

A technology of screw pile and steel pipe, applied in sheet pile wall, foundation structure engineering, construction and other directions, can solve the problems of difficult drilling, low overall stiffness, steel corrosion, etc., to improve the stability of the pile body and the structural bearing capacity, improve Flexural stiffness and structural bearing capacity, the effect of improving corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

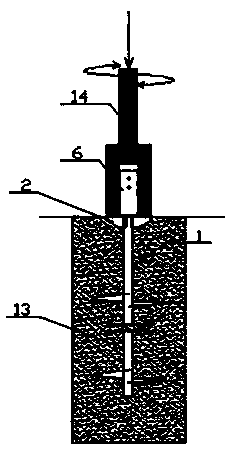

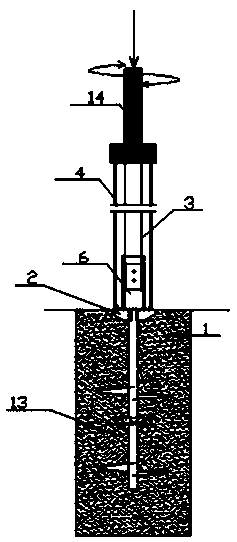

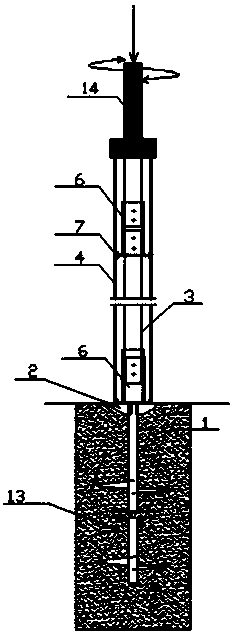

[0035] Such as figure 1 , figure 2 with image 3 As shown, a grouting type steel pipe screw pile, including a solid square rod or steel pipe 1 welded with spiral blades in the guiding part, an annular soil squeezing device 2, an extension steel pipe 3, a protective wall casing 4, cement-based slurry 5 and connecting steel Sleeve 6; the top end of the solid square bar or steel pipe 1 welded to the spiral blade is fixedly connected with the annular earth squeezing device 2 by welding or bolts, and the top end of the annular earth squeezing device 2 is provided with one or more extended steel pipes 3. The steel pipe 3 of the extended part of the bottom section is fixedly connected with the annular soil squeezing device 2 through the connecting steel sleeve 6 and bolts, and the steel pipes 3 of the adjacent two extended parts are fixedly connected through the connecting steel sleeve 6 and bolts; each section is extended The outer sides of some steel pipes 3 are provided with co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com