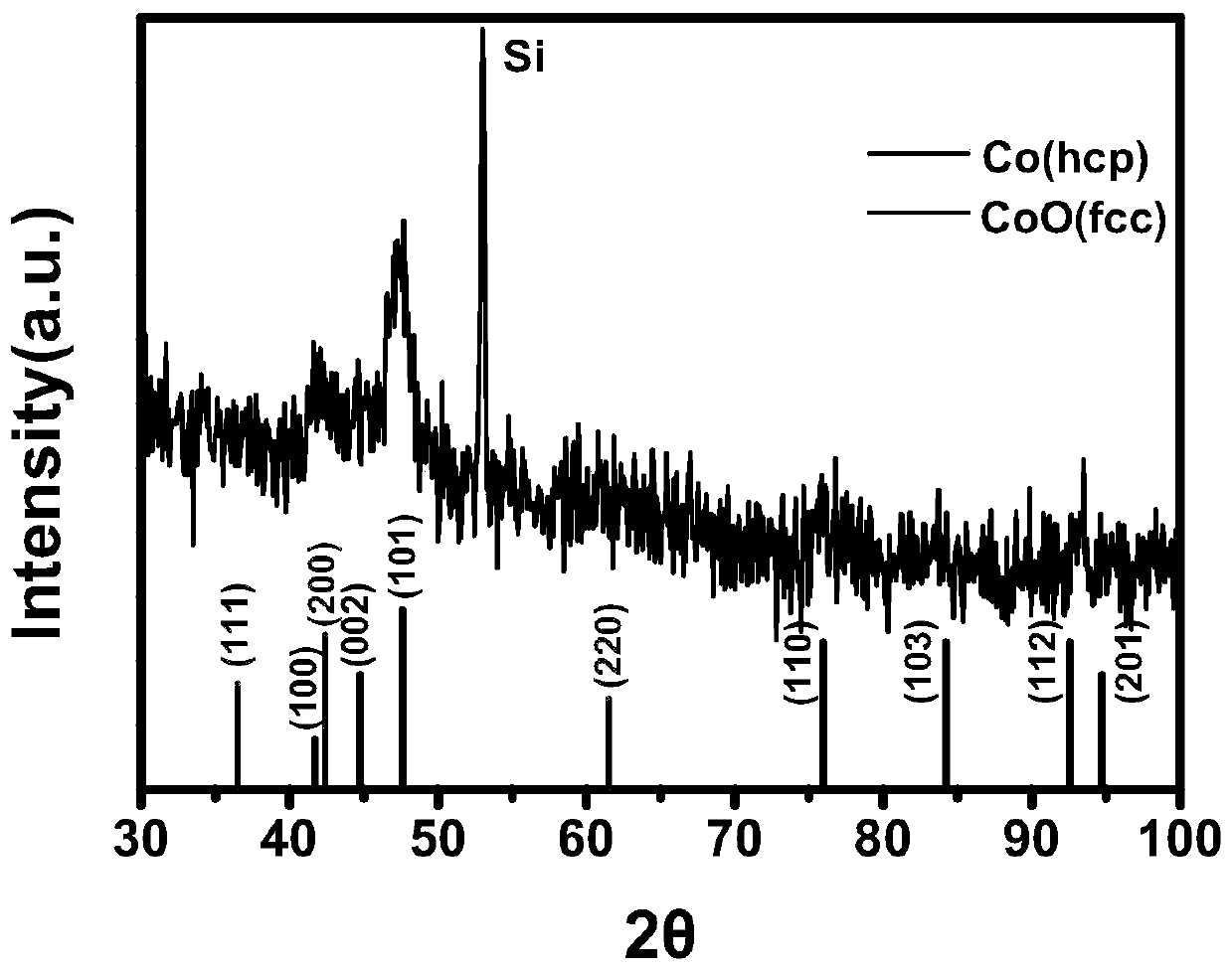

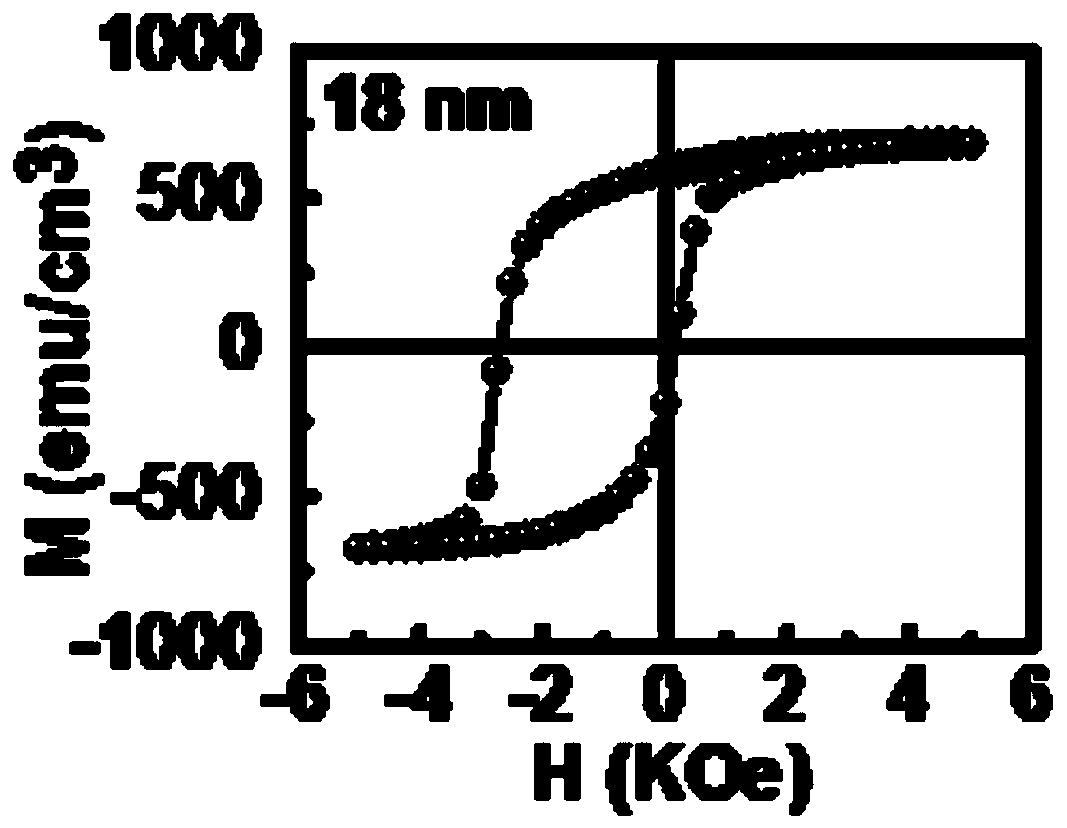

Co/CoO nano composite film with zero-field cooling exchange bias effect as well as preparation method and application of Co/CoO nano composite film

A nano-composite, bias effect technology, applied in the manufacture/processing of electromagnetic devices, magnetic field-controlled resistors, material selection, etc., can solve problems such as inconvenience, and achieve the effect of a simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

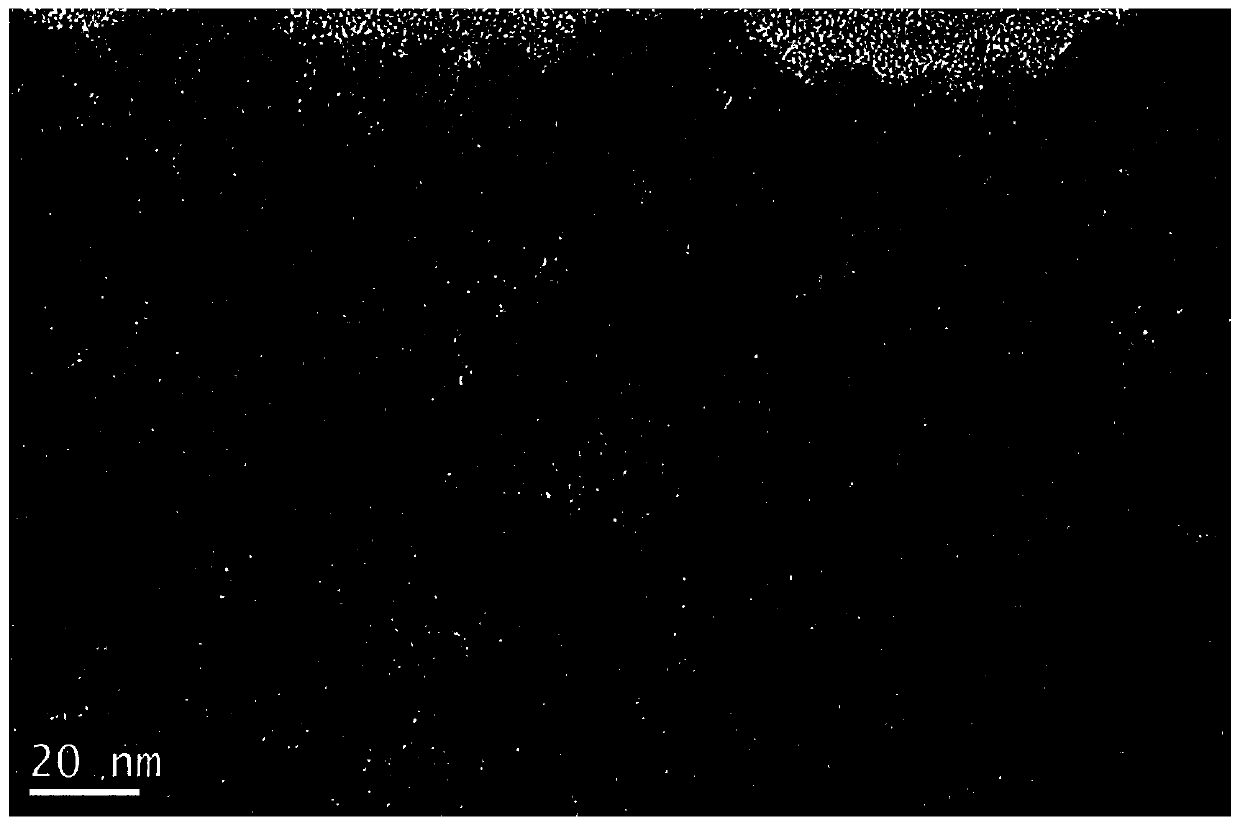

[0047] This embodiment provides a method for preparing a Co / CoO nanocomposite film, including the following steps:

[0048] Step S1: Select a single crystal Si substrate with a thickness of 0.5mm and perform pretreatment, that is, use water, acetone and ethanol to perform ultrasonic cleaning on the single crystal Si substrate in sequence, cycle three times, and finally blow dry with a nitrogen gun.

[0049] Step S2: Fix the single crystal Si substrate in the magnetron sputtering apparatus, fix the single crystal Si substrate on the sample holder, put it into the sample chamber of the magnetron sputtering apparatus, close the door of the sample chamber, and respectively Vacuum the sampling chamber and the sputtering chamber. When the vacuum difference between the sampling chamber and the sputtering chamber is less than 1 Pa, open the gate valve connecting the sampling chamber and the sputtering chamber, and send the sample carrier from the sampling chamber to to the sputtering ...

Embodiment 2

[0055] The difference between embodiment 2 and embodiment 1 is that the sputtering time in step S3 is 36s, so that a 3.6nm thick Co / CoO nanoparticle composite film is formed on the single crystal Si substrate.

Embodiment 3

[0057] The difference between embodiment 3 and embodiment 1 is that the sputtering time in step S3 is 1080 s, so that a 108 nm thick Co / CoO nanoparticle composite film is formed on the single crystal Si substrate.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com