A kind of composite thin film and its preparation method and self-starting mode-locked fiber laser device

A composite thin film, one-half technology, used in lasers, semiconductor lasers, laser parts, etc., can solve problems such as aggravating long-distance communication bit error rate, unfavorable communication quality, pulse timing jitter, etc., and achieve a high damage resistance threshold , the effect of high preparation temperature and large modulation depth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

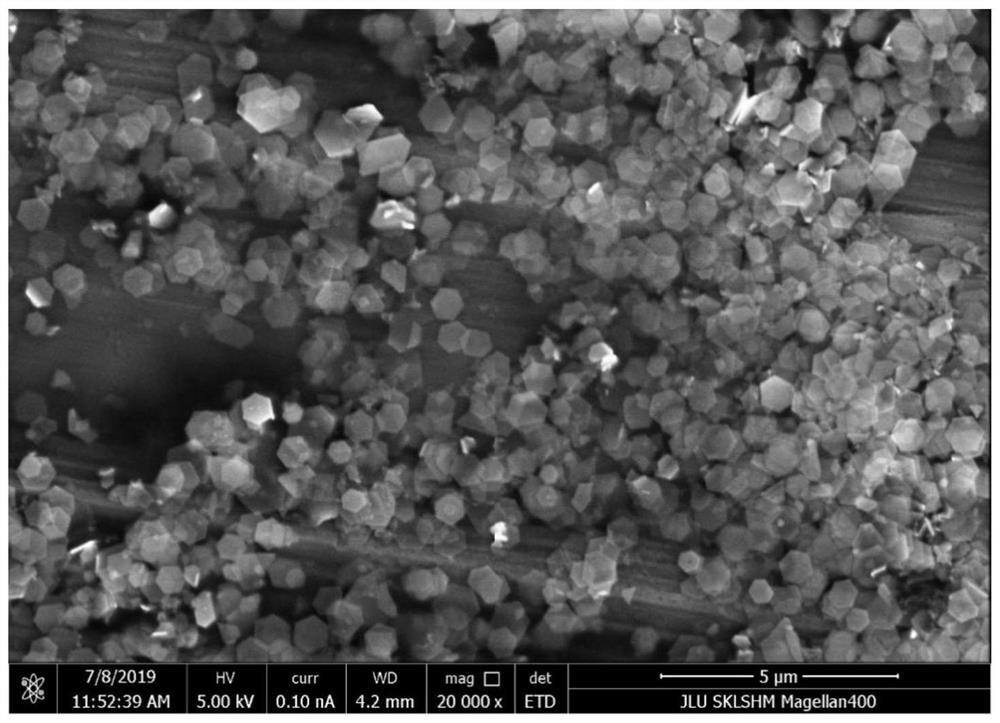

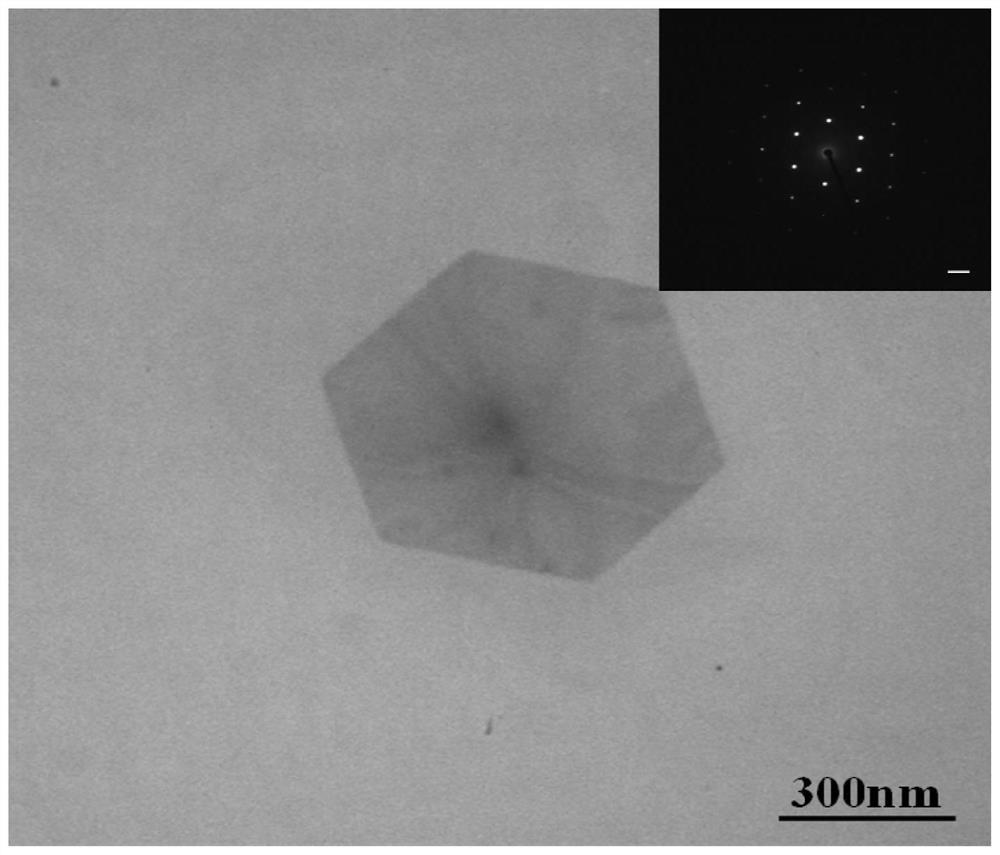

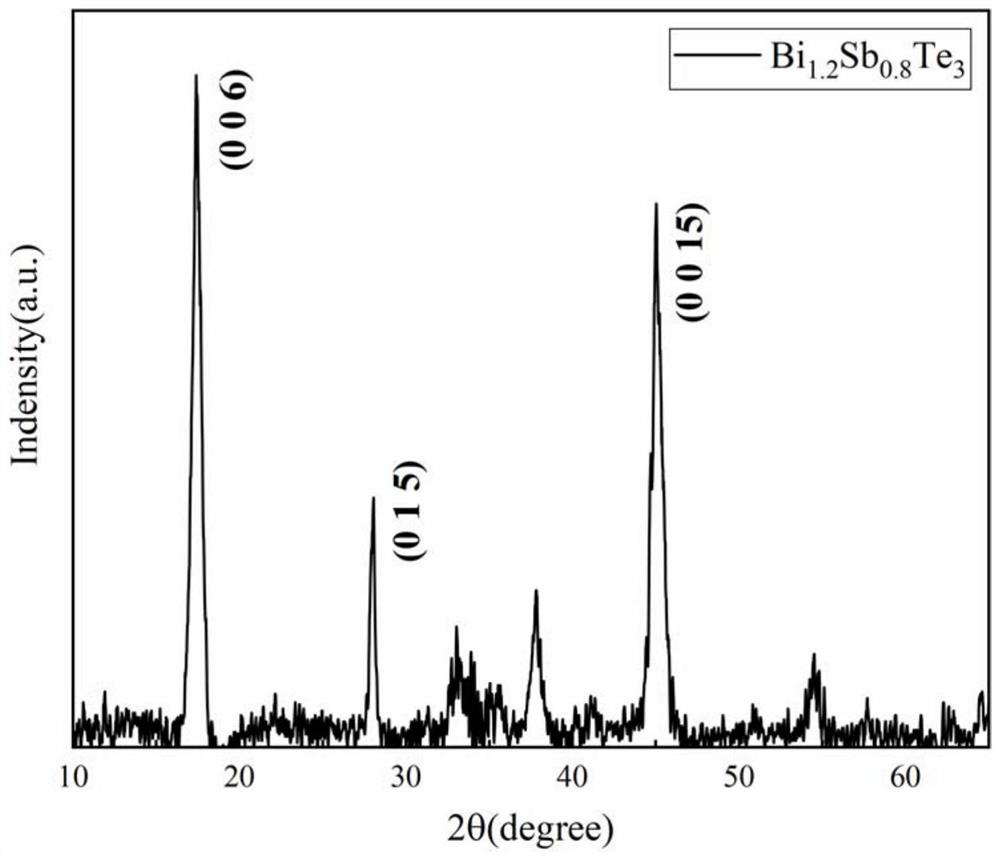

[0057] see Figure 1-7 , the application provides a kind of composite film, and described composite film is made up of the raw material of following weight part:

[0058] 3 parts of polyvinylpyrrolidone, 16 parts of ethylene glycol, 76 parts of sodium hydroxide, 2 parts of bismuth chloride, 1 part of antimony chloride and 11 parts of sodium tellurite.

Embodiment 2

[0060] The application provides a composite film, the composite film is made up of the following raw materials in parts by weight:

[0061] 4 parts of polyvinylpyrrolidone, 17 parts of ethylene glycol, 77 parts of sodium hydroxide, 3 parts of bismuth chloride, 2 parts of antimony chloride and 12 parts of sodium tellurite.

Embodiment 3

[0063] The application provides a composite film, the composite film is made up of the following raw materials in parts by weight:

[0064] 7 parts of polyvinylpyrrolidone, 20 parts of ethylene glycol, 80 parts of sodium hydroxide, 6 parts of bismuth chloride, 4 parts of antimony chloride and 15 parts of sodium tellurite.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com