Method for making crispy biscuits with characteristic of delaying starch digestion by utilizing microwave enzyme-inactivated bacteria-reduced wheat middling

A technology of wheat flour and crispy biscuits, which is applied in the field of food processing, can solve the problems that need to be developed, achieve the effect of reducing lipase activity and microbial content, and improving food safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

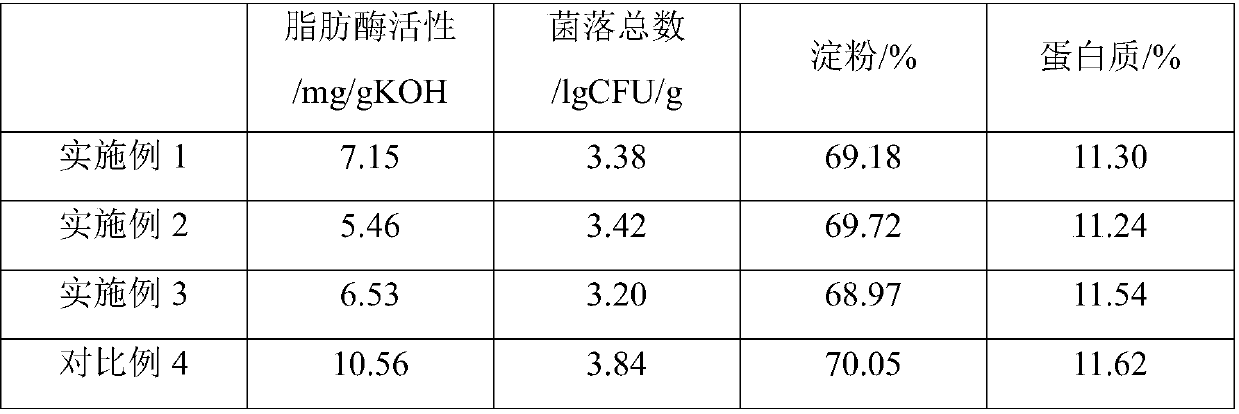

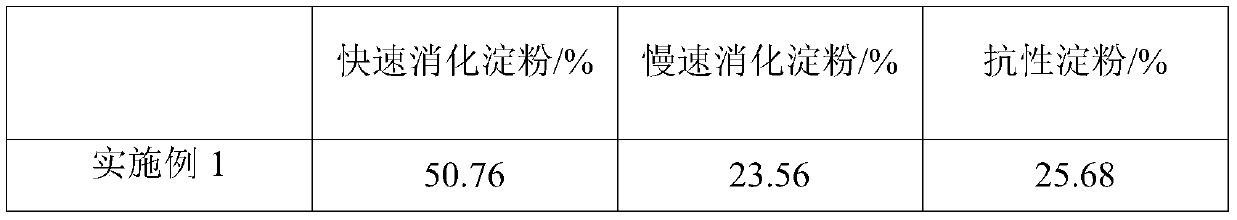

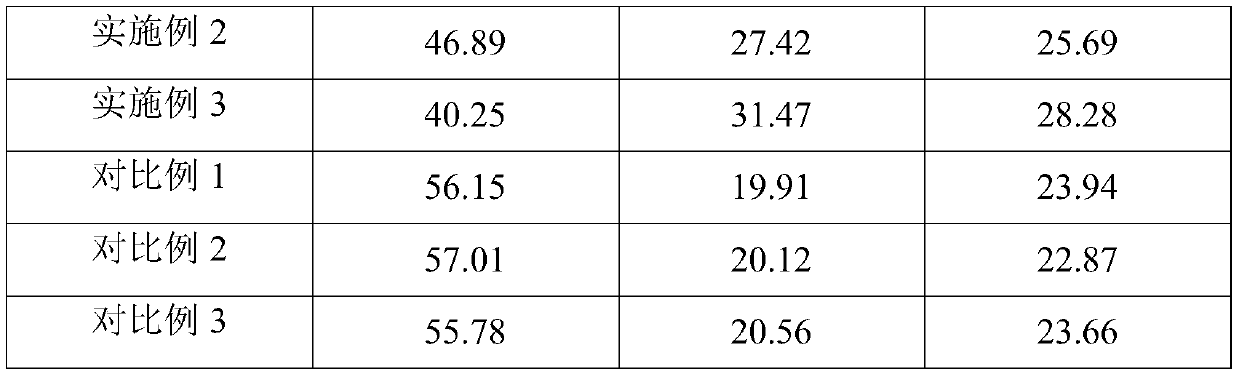

Embodiment 1

[0031] The method for making crispy biscuits with the characteristic of delaying starch digestion by using microwave blunt enzyme reduced bacteria wheat flour is as follows:

[0032] The process of preparing blunt enzyme reduced bacterium wheat secondary flour is as follows:

[0033] S101, microwave, evenly spread the wheat flour on the flat plate, the thickness of the material is 0.5mm, put the flat plate in the microwave equipment, the microwave power is 200W, and process for 20s;

[0034] S102, cooling, cooling the microwave-treated wheat secondary flour to room temperature to prepare blunted enzyme-reduced wheat secondary flour;

[0035] Processed crispy biscuits with delayed starch digestion properties as:

[0036] S201, sieving, passing the low-gluten flour used for processing, blunted enzyme-reduced bacterium wheat flour respectively through a 60-mesh sieve;

[0037] S202, stir the ingredients, weigh 90 parts of low-gluten flour, 10 parts of blunt enzyme reduced bacte...

Embodiment 2

[0042] The method for making crispy biscuits with the characteristic of delaying starch digestion by using microwave blunt enzyme reduced bacteria wheat flour is as follows:

[0043] The process of preparing blunt enzyme reduced bacterium wheat secondary flour is as follows:

[0044] S101, microwave, evenly spread the wheat flour on the plate, the thickness of the material is 2mm, put the plate in the microwave equipment, the microwave power is 400W, and process for 40s;

[0045] S102, cooling, cooling the microwave-treated wheat secondary flour to room temperature to prepare blunted enzyme-reduced wheat secondary flour;

[0046] Processed crispy biscuits with delayed starch digestion properties as:

[0047] S201, sieving, passing the low-gluten flour and blunt enzyme-reduced bacterium wheat flour used for processing through an 80-mesh sieve respectively;

[0048] S202, stir the ingredients, weigh 75 parts of low-gluten flour, 25 parts of blunt enzyme reduced bacterium wheat f...

Embodiment 3

[0053] The method for making crispy biscuits with the characteristic of delaying starch digestion by using microwave blunt enzyme reduced bacteria wheat flour is as follows:

[0054] The process of preparing blunt enzyme reduced bacterium wheat secondary flour is as follows:

[0055] S101, microwave, evenly spread the wheat flour on the plate, the thickness of the material is 5mm, put the plate in the microwave equipment, the microwave power is 600W, and process for 60s;

[0056] S102, cooling, cooling the microwave-treated wheat secondary flour to room temperature to prepare blunted enzyme-reduced wheat secondary flour;

[0057] Processed crispy biscuits with delayed starch digestion properties as:

[0058] S201, sieving, passing the low-gluten flour used for processing, blunted enzyme-reduced bacterium wheat flour respectively through a 60-mesh sieve;

[0059] S202, stir the ingredients, weigh 50 parts of low-gluten flour, 50 parts of blunt enzyme reduced bacterium wheat f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com