Ultrasonic cutting device and using method thereof

A cutting device and ultrasonic technology, applied in metal processing, stone processing tools, manufacturing tools, etc., can solve the problems of long adjustment time of coaxiality, low reliability, large structure occupied space, etc., and improve the surface roughness of workpiece processing. The effect of improving the drilling efficiency and improving the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

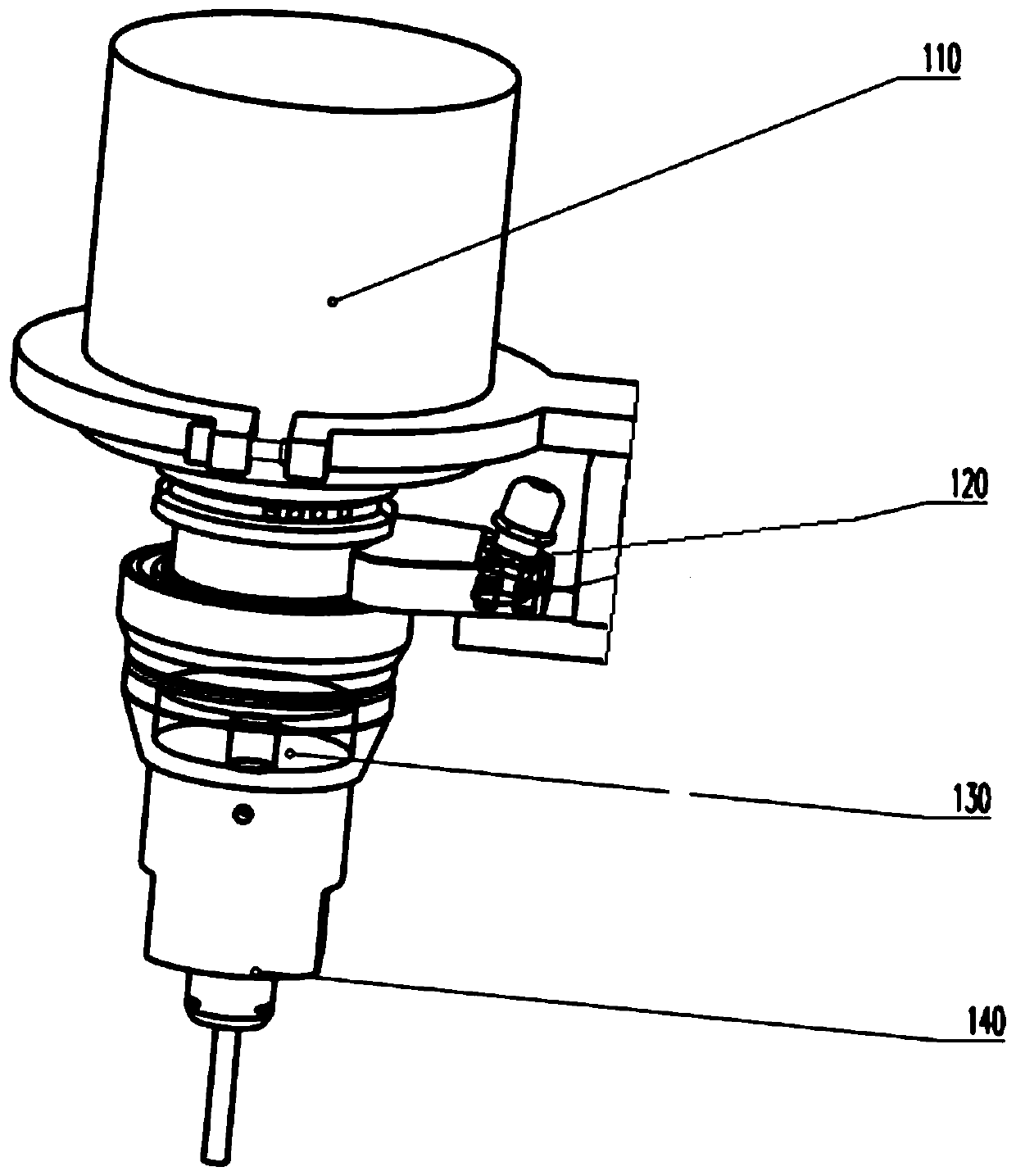

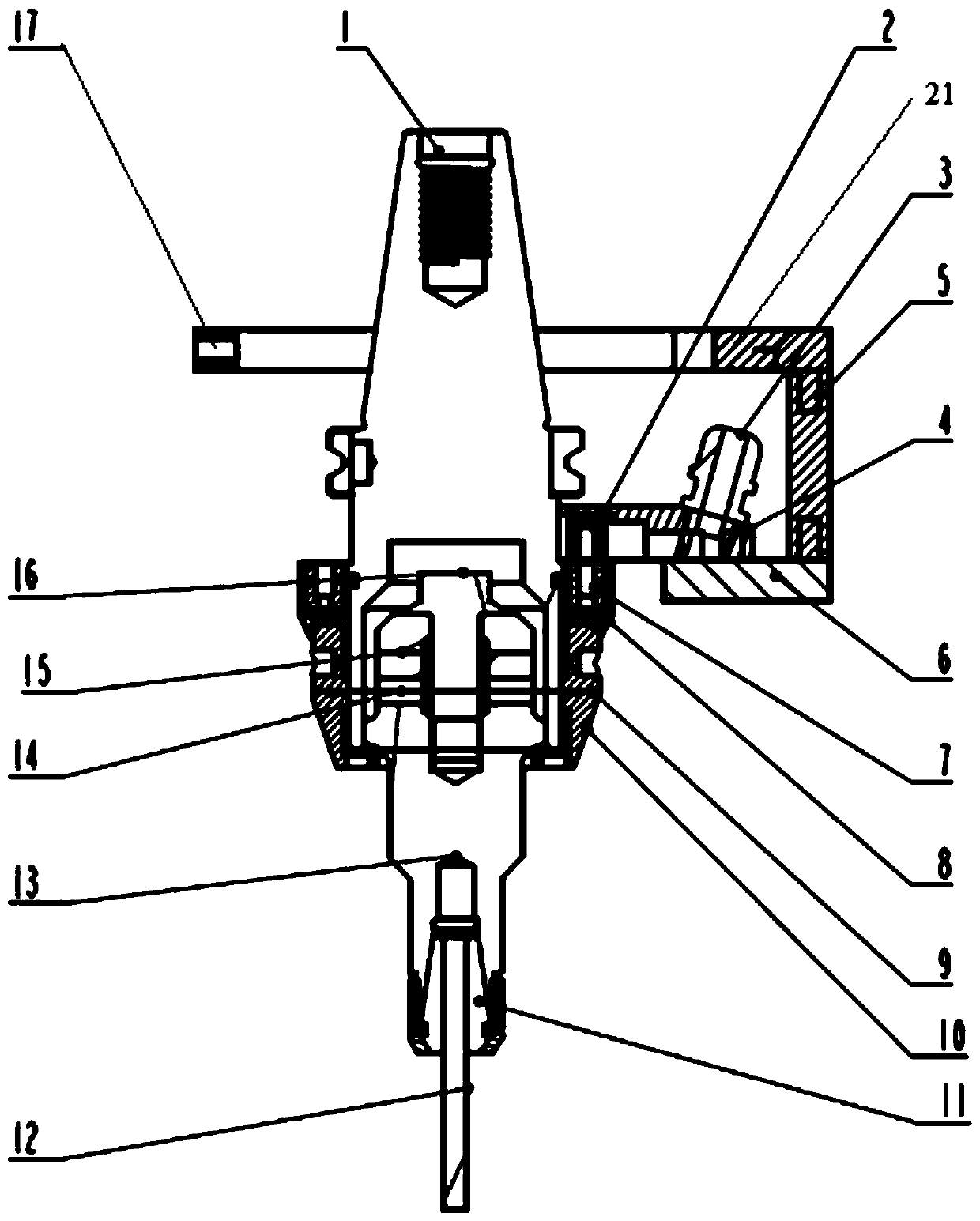

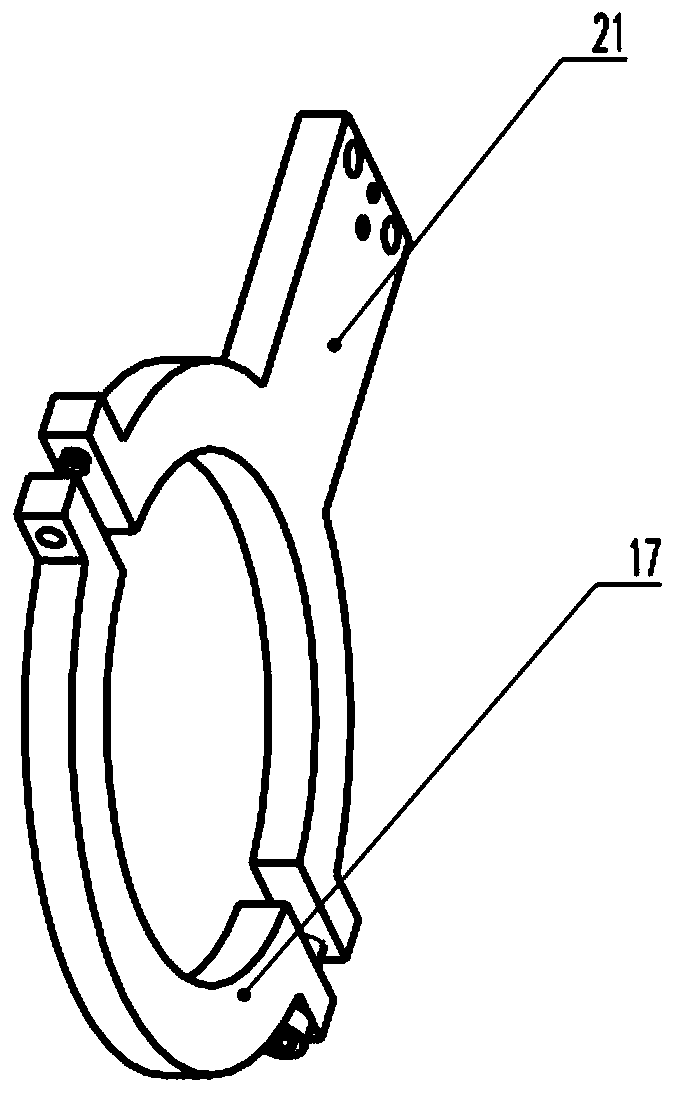

[0037] The appearance of the ultrasonic cutting device of the present invention is as follows: figure 1 As shown, it includes a spindle interface module 110 , a power transmission module 120 , an ultrasonic generation module 130 , and a tool holding module 140 . Among them, such as figure 2 As shown, the spindle interface module 110 includes a tool holder 1 , a radial connecting plate 6 , an axial connecting plate 5 , a first fixing ring 17 , and a second fixing ring 21 . Wherein, the handle 1 is tapered, and its small diameter end is coaxially connected with the rotating spindle of the machine tool through a broach mechanism, and rotates at high speed simultaneously with the spindle. like image 3 As shown, the first fixed ring 17 and the second fixed ring 21 are semicircular, and there are radial bolt holes at both ends of the first fixed ring 17 and the second fixed ring 21 respectively. The first fixed ring 17 and the second fixed ring The fixing ring 21 is fastened on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com