Preparation method of fluorine-containing diamine monomer with substituted C6 side chain

A technology of fluorine-containing diamines and monomers, which is applied in the preparation of carboxylic acid amides, the preparation of organic compounds, chemical instruments and methods, etc. It can solve the problems of high molecular weight of diamine monomers, restrictions on the development of polyimides, and reduction of nitro groups. Difficulties and other problems, to achieve the effect of high synthesis yield, increase light transmittance, reduce order and symmetry

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

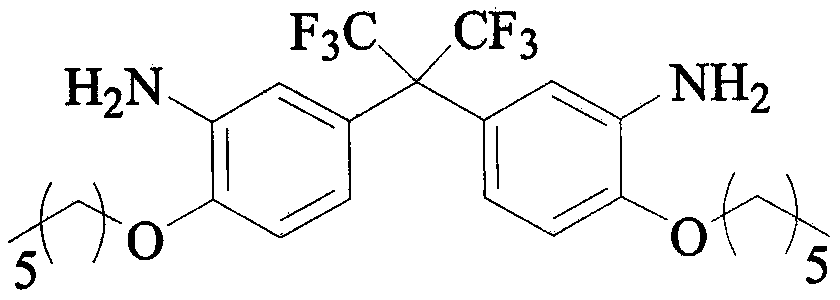

[0027] Step 1: Add 1.2L DMAC, 1000g 2,2-bis(3-amino-4-sodium phenolate)hexafluoropropane and 800g bromo-C6 alkane to a 10L four-necked reaction flask in sequence, start stirring and heating, and maintain React at 80°C for 2-3 hours. After the reaction of the raw materials is completed, turn off the heating, pour out the reaction liquid, and filter while it is hot. The upper layer of filter cake is the by-product sodium bromide, which is collected and stored. The filtrate is naturally cooled to room temperature, and then added to 2.4 Quenched in L water, a large amount of solids will appear at this time, filter with suction, wash the filter cake with 3.5L of water, and dry the filter cake in vacuum to obtain 1173g of pure C6-FN.

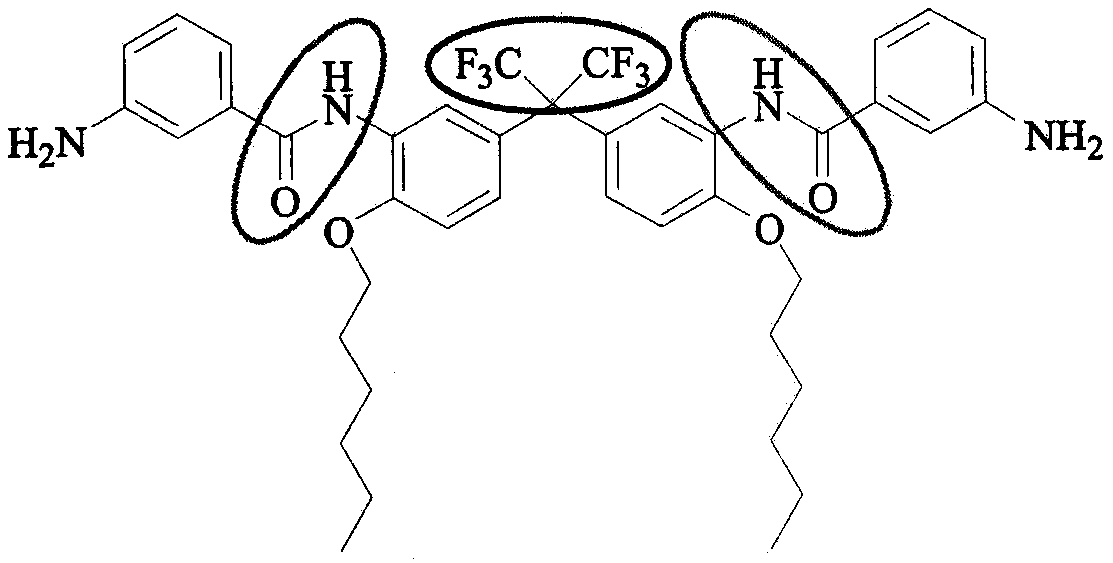

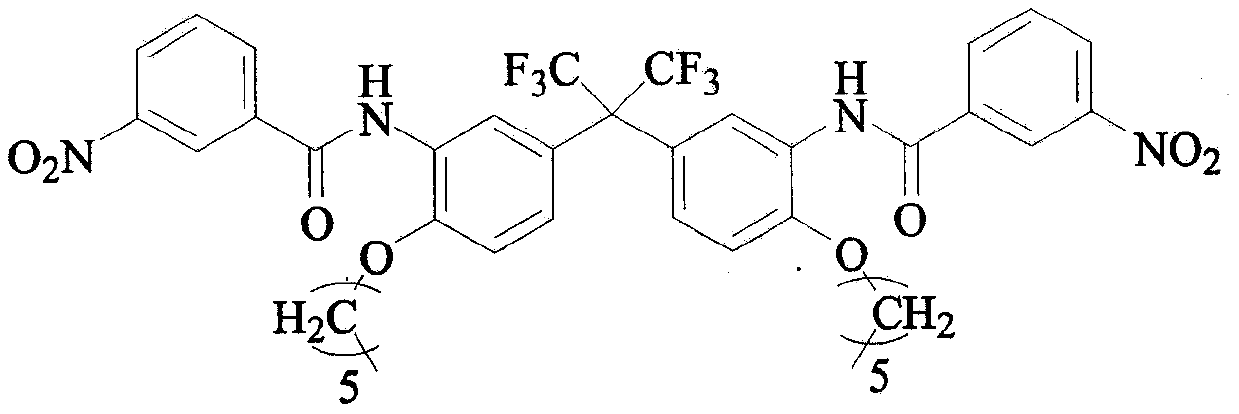

[0028] The second step: add 1173g C6-FN and 550mL NMP to the 10L four-necked reaction flask, start stirring, and then slowly dropwise add the mixed solution of 812g m-nitrobenzoyl chloride and 550mL NMP to it, and control the concentration of the react...

Embodiment 2

[0031] Step 1: Add 24.3L DMAC, 1000g 2,2-bis(3-amino-4-sodium phenolate) hexafluoropropane and 4000g bromo-C6 alkane to the 30L double-layer glass reactor, start stirring and heating, Maintain the reaction at 166°C for 2-3 hours. After the reaction of the raw materials is completed, turn off the heating, release the reaction liquid, and filter while it is hot. The upper layer of filter cake is the by-product sodium bromide, which is collected and stored. The filtrate is naturally cooled to room temperature, and then added to 48.6 Quenched in L water, a large amount of solids will appear at this time, filter with suction, wash the filter cake with 3.5L of water, and dry the filter cake in vacuum to obtain 1238g of pure C6-FN.

[0032] Step 2: Add 1238g C6-FN and 11.5L NMP to the 30L double-layer glass reactor, start stirring and jacket cooling, when the temperature of the reaction solution drops to 0°C, slowly add 4286g m-nitrobenzene dropwise For the mixed solution of formyl c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com