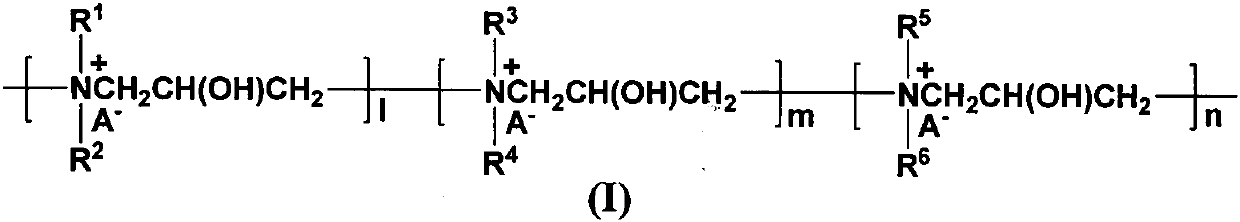

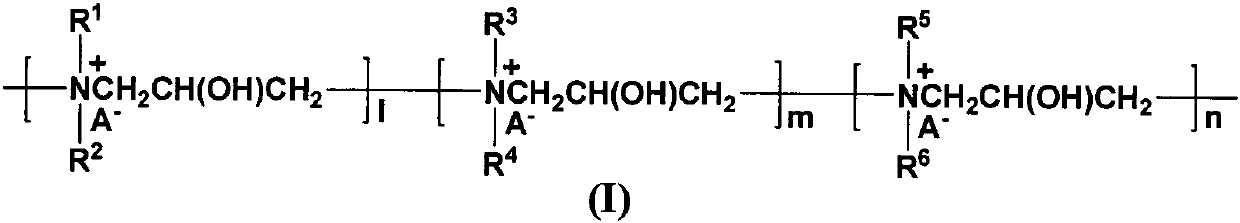

Method for synthesizing polyquaternary ammonium salt

A polyquaternary ammonium salt and synthesis method technology, which is applied in coatings, conductive coatings, epoxy resin coatings, etc., can solve the problems of high cost of use, incompatibility of epoxy resins, and large additions, so as to reduce orderly Sexuality and symmetry, improvement of antistatic performance, effect of improving exercise ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

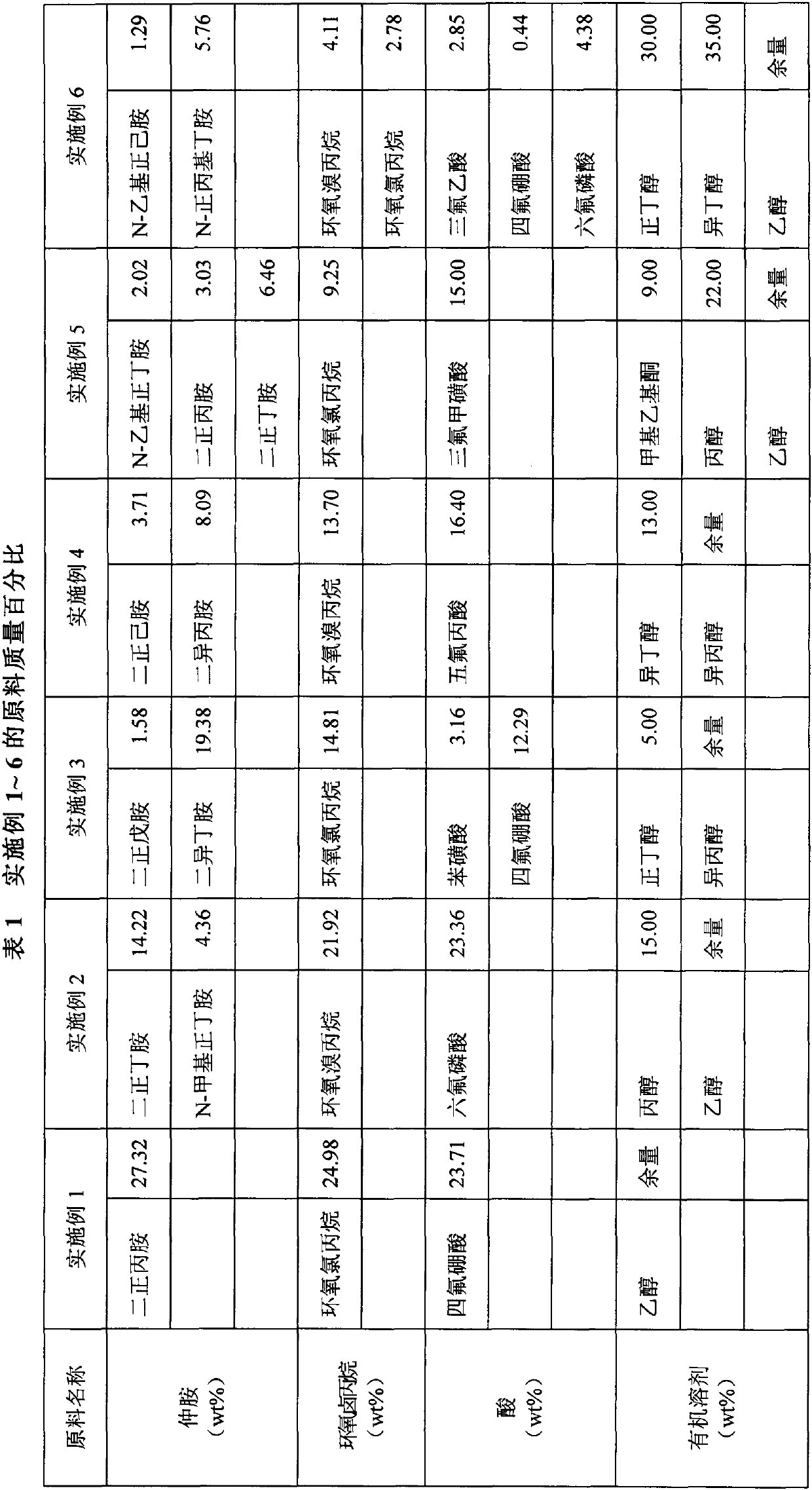

Embodiment 1

[0035] According to the mass percentages of the organic solvent, secondary amine, epihalohydrin and acid in Example 1 in Table 1, first, under nitrogen protection and room temperature water bath cooling, the organic solvent and the secondary amine were mixed, and the epoxy halogen was added dropwise under stirring Addition reaction of propane, continue to react for 0.5h after epihalohydrin is added dropwise to obtain a solution of tertiary amine compound; secondly, heat the solution of tertiary amine compound to carry out quaternization polymerization reaction, the reaction temperature is 50°C, and the reaction time is 25h. After the reaction is completed, a solution of polyquaternium hydrohalide is obtained; thirdly, the solution of polyquaternium hydrohalide is treated with a strong basic anion exchange resin until the liquid phase detects no halogen ions, and then filtered to obtain polyquaternium Alkali solution; Fourth, under cooling in a water bath at room temperature, ne...

Embodiment 2

[0038]According to the mass percentages of the organic solvent, secondary amine, epihalohydrin and acid in Example 2 in Table 1, first, under nitrogen protection and room temperature water bath cooling, the organic solvent and the secondary amine were mixed, and the epoxy halogen was added dropwise under stirring. Addition reaction of propane, continue to react for 1.5h after epihalohydrin is added dropwise to obtain a solution of tertiary amine compound; secondly, heat the solution of tertiary amine compound for quaternization polymerization reaction, the reaction temperature is 60°C, and the reaction time is 20h. After the reaction is completed, a solution of polyquaternium hydrohalide is obtained; thirdly, the solution of polyquaternium hydrohalide is treated with a strong basic anion exchange resin until the liquid phase detects no halogen ions, and then filtered to obtain polyquaternium Alkali solution; Fourth, under cooling in a water bath at room temperature, neutralize ...

Embodiment 3

[0040] According to the mass percentages of the organic solvent, secondary amine, epihalohydrin and acid in Example 3 in Table 1, first, under nitrogen protection and room temperature water bath cooling, the organic solvent and the secondary amine were mixed, and the epoxy halogen was added dropwise under stirring. Addition reaction of propane, continue to react for 2.5h after epihalohydrin is added dropwise to obtain a solution of tertiary amine compound; secondly, heat the solution of tertiary amine compound for quaternization polymerization reaction, the reaction temperature is 65°C, and the reaction time is 15h. After the reaction is completed, a solution of polyquaternium hydrohalide is obtained; thirdly, the solution of polyquaternium hydrohalide is treated with a strong basic anion exchange resin until the liquid phase detects no halogen ions, and then filtered to obtain polyquaternium Alkali solution; Fourth, under cooling in a water bath at room temperature, neutralize...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com