Pressure double-control mold grouting all-in-one machine

An all-in-one machine with mold technology, which is applied in the direction of liquid variable capacity machinery, mechanical equipment, machines/engines, etc., can solve the problem of uncontrollable grouting volume, grouting time and grouting pressure, and the difficulty of combining grout with hardened concrete. Overall, high compressive and flexural strength of the grouting pipe, to improve the grouting efficiency, easy to disassemble and clean, and easy to maintain

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

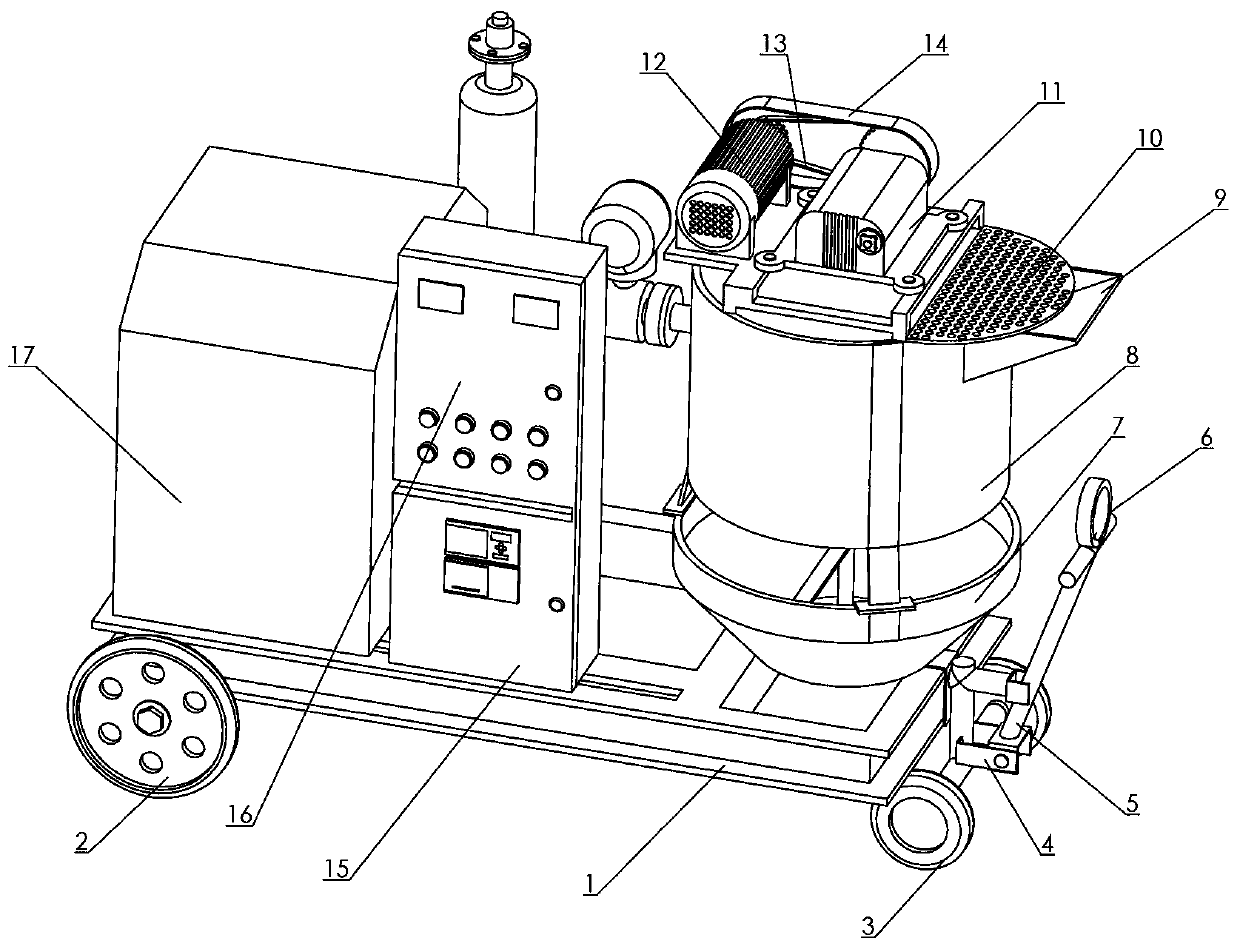

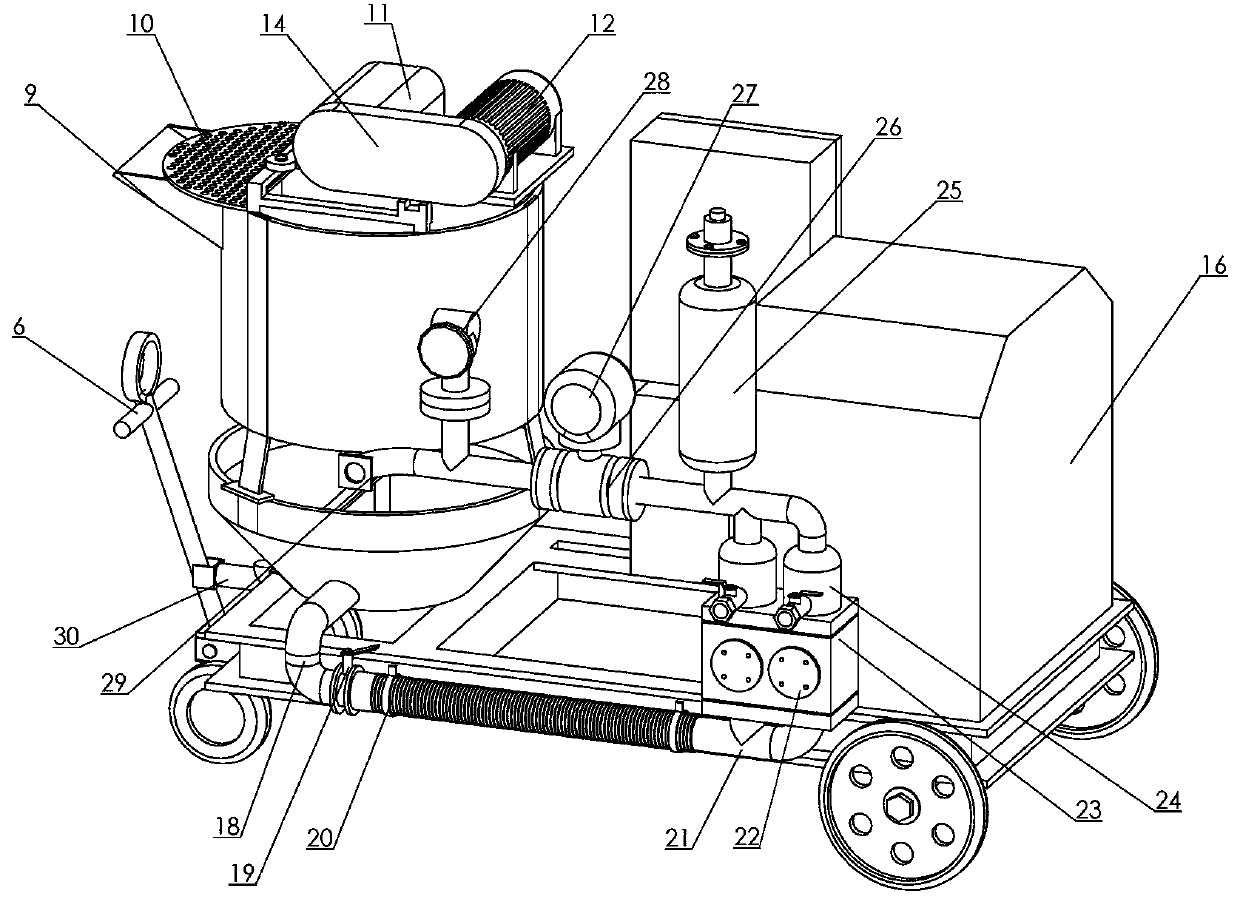

[0036] as attached Figure 1-2 As shown, the present invention includes a walking mechanism, a pulping mechanism, a grouting mechanism, a pumping mechanism and a PLC control mechanism,

[0037] The walking mechanism is composed of a chassis 1, a front wheel 2, a rear wheel 3 and a hand-held pull rod device. The hand-held pull rod device includes a pull rod seat 4 and a pull rod 5 hinged with the pull rod seat 4. The frame 1 is also provided with The pull rod limiting card 30, the front end of the pull rod limiting card 30 is U-shaped, and its recessed part is adapted to the pull rod 5, and the top of the pull rod 5 is provided with a push rod 6.

[0038] The pulping mechanism includes a pulping barrel 8 and a slurry storage tank 7 arranged at the lower end of the pulping barrel 8. The slurry storage tank 7 is fixedly arranged on the upper end of the chassis 1, and a slurry storage tank is arranged in the slurry storage tank 7. Agitator, the pulping barrel 8 is provided with a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com